Locking structure of axial cylinder

A lock structure, axial marble technology, applied in cylinder marble locks, locks with turning keys, building locks, etc., can solve the problems of difficult radian segmentation manufacturing process, complex combination algorithm, short service life, etc. The effect of mutual opening rate, simple production process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

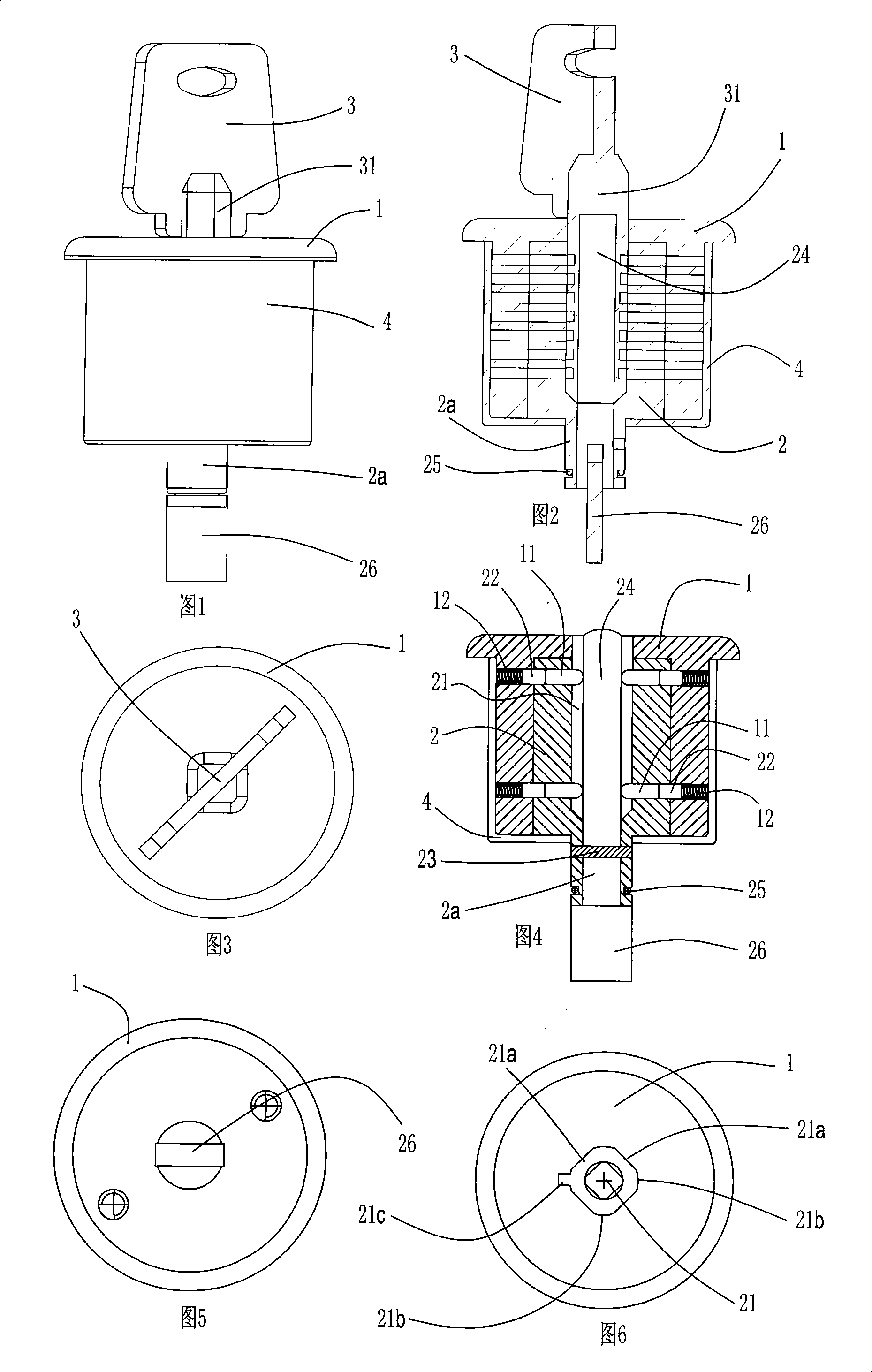

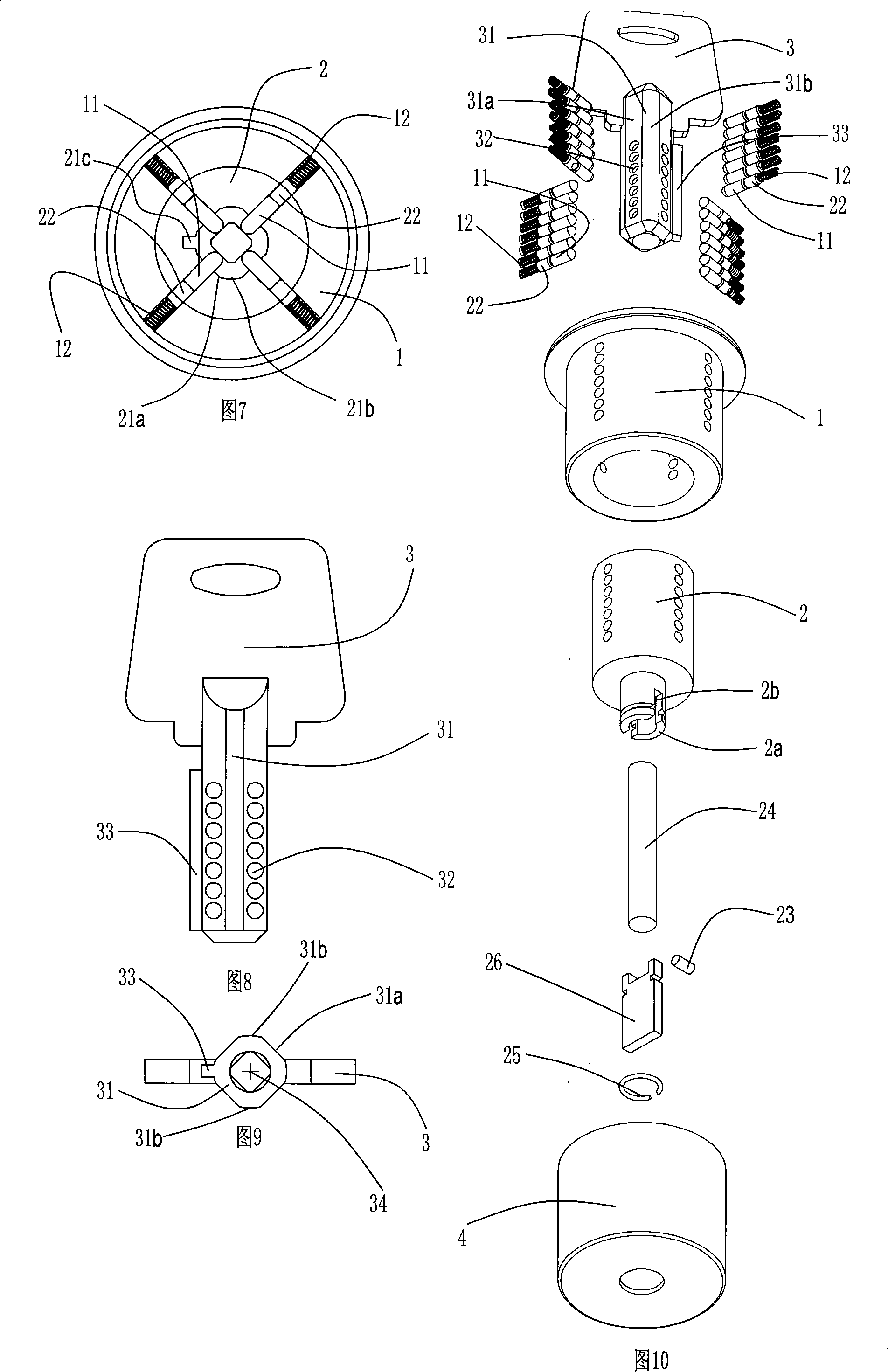

[0028] The embodiment shown in Fig. 1 to Fig. 10, reference number description: lock body 1, lock body pin 11, spring member 12, lock core 2, extension shaft 2a, notch 2b, lock hole 21, inner edge body 21a, inner Transitional arc edge 21b, positioning groove 21c, lock cylinder pin 22, positioning pin 23, positioning guide post 24, snap spring 25, opening and closing rotating piece 26, key 3, latch shaft 31, vertical body 31a, transitional arc edge 31b , Pinhole 32, positioning edge 33, positioning lock hole 34, outer shell 4.

[0029] In an embodiment of the present invention, a lock structure with axial pins includes a lock body 1, a lock cylinder 2 is installed in the lock body 1, and a key 3 is equipped with the lock cylinder 2, and a bolt shaft is formed at the lower end of the key 3 31, the bolt shaft 31 is shaped on four vertical planes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com