Process for depriving acetyl of kanjak glucomannosan

A technology of glucomannan acetylation and konjac glucomannan, applied in the field of removing acetylation of konjac glucomannan, achieving the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Deacetylation of 50 grams of konjac glucomannan:

[0019] Step 1: Dry the konjac glucomannan at 50° C. with a blower until the water content is 4%, weigh 50 g of the dried konjac glucomannan, and add 0.5 g of sodium hydroxide as an alkaline modifier;

[0020] The second step: mix the above-mentioned konjac glucomannan and grinding medium evenly, add it into the grinding jar of the vibrating mill, seal the grinding jar, start the vibrating mill to grind for 60 minutes; the volume of the grinding medium is 50% of the volume of the grinding jar, and the grinding medium A glass ball with a diameter of 8mm is used;

[0021] Step 3: Separating the grinding medium by sieving to obtain deacetylated konjac glucomannan.

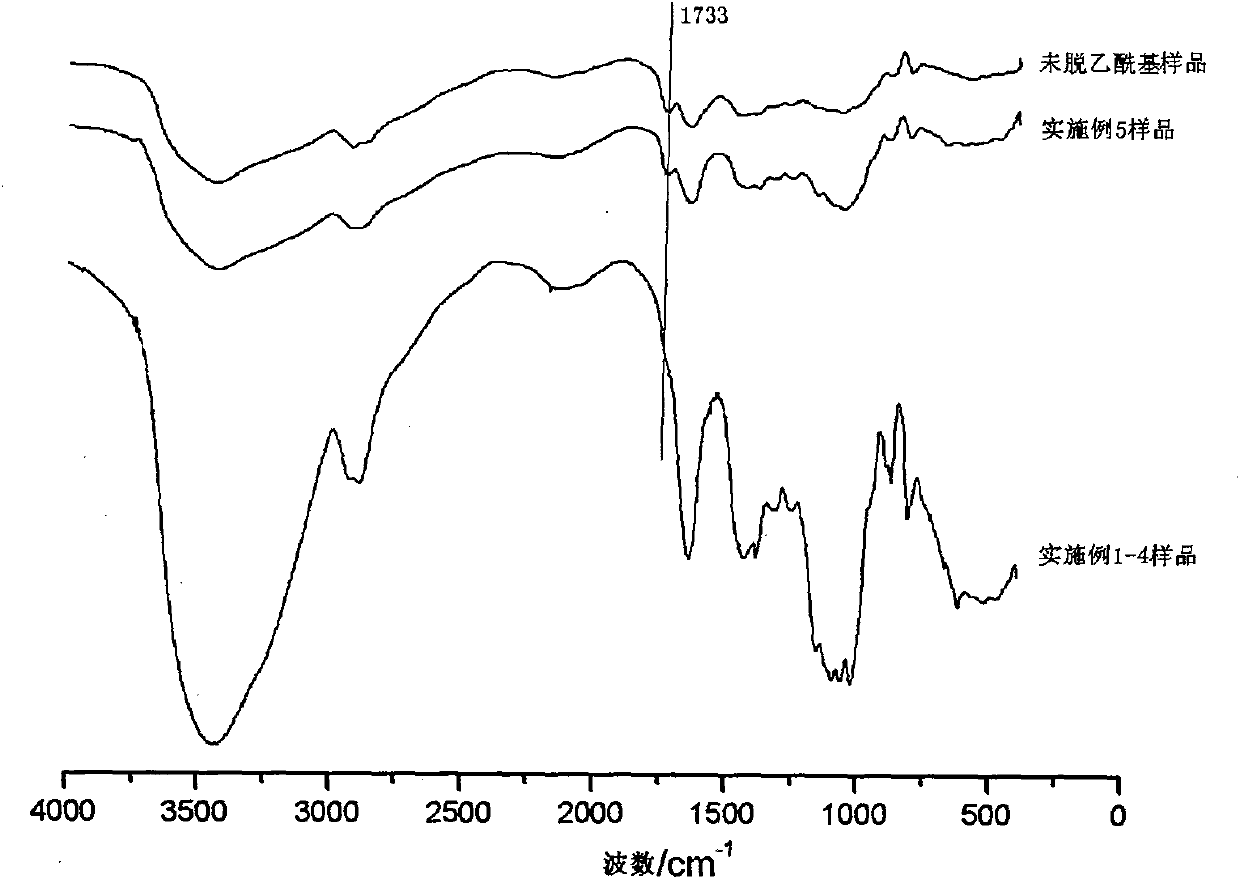

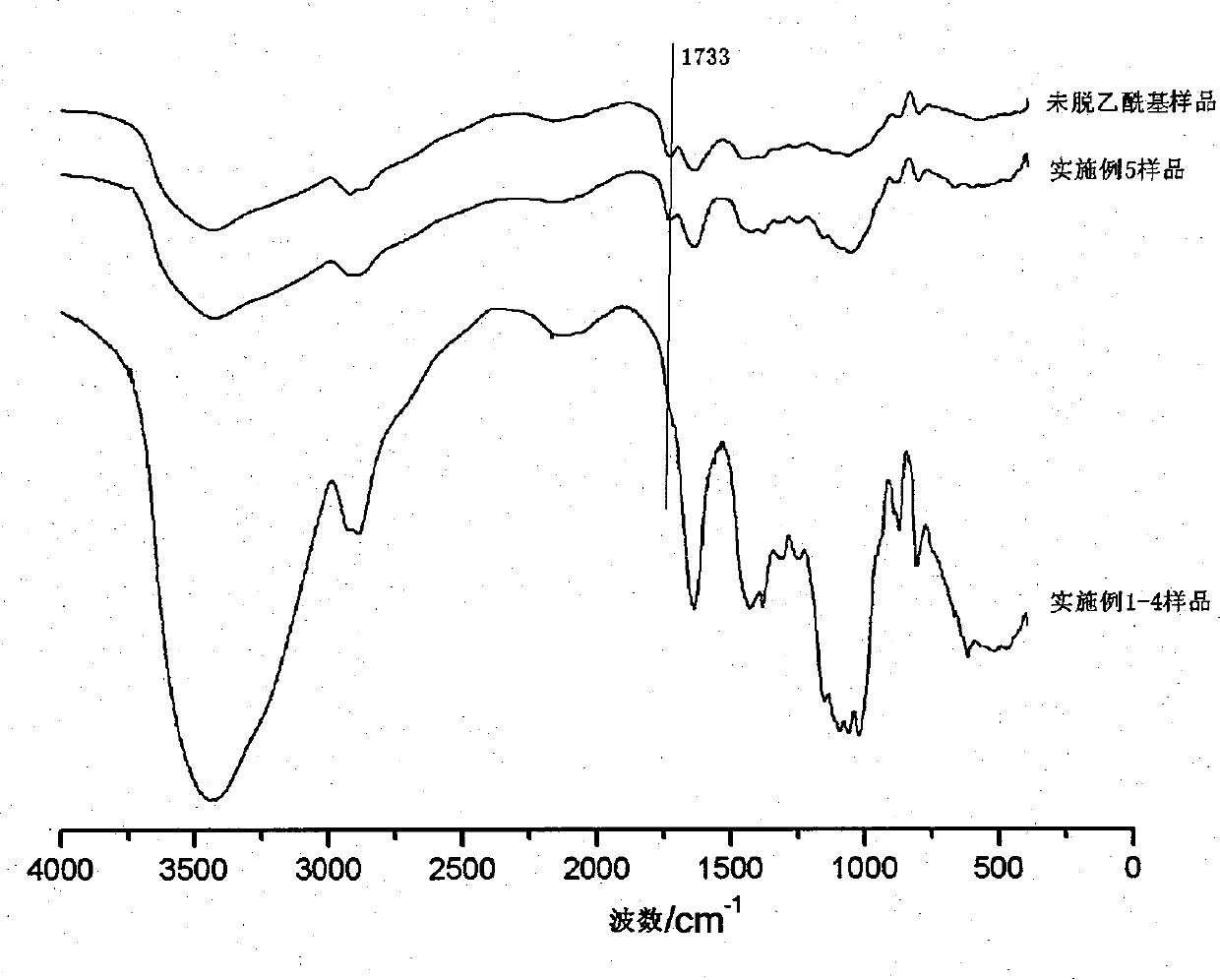

[0022] The mass percent of acetyl group in the gained konjac glucomannan is shown in Table 1, and the infrared analysis spectrogram is as shown in Table 1. figure 1 shown.

Embodiment 2

[0024] Deacetylation of 50 grams of konjac glucomannan:

[0025] Step 1: Dry the konjac glucomannan in a vacuum oven at 80° C. and vacuum-dry it to a water content of 2%, weigh 50 g of the dried konjac glucomannan, and add 2.5 grams of potassium hydroxide as a modifier;

[0026] The second step: mix the above-mentioned konjac glucomannan and the grinding medium evenly, add it into the grinding tank of the vibrating mill, seal the grinding tank, start the vibrating mill to grind for 50 minutes; the volume of the grinding medium is 85% of the volume of the grinding tank, and the grinding medium Use alumina balls with diameters of 15mm and 8mm respectively, and the volume ratio of the two alumina balls is 2:1;

[0027] Step 3: Separating the grinding medium by sieving to obtain deacetylated konjac glucomannan.

[0028] The mass percentage of acetyl group in the gained konjac glucomannan is as shown in Table 1, and the infrared analysis spectrogram of gained konjac glucomannan is...

Embodiment 3

[0030] Deacetylation of 50 grams of konjac glucomannan:

[0031] Step 1: Dry the konjac glucomannan at 70° C. to a water content of 3% with a blast dryer, weigh 50 g of the dried konjac glucomannan, and add 0.25 g of calcium hydroxide as a modifier;

[0032] The second step: mix the above-mentioned konjac glucomannan and grinding medium evenly, add it into the grinding tank of the vibrating mill, seal the grinding tank, start the vibrating mill to grind for 20 minutes; the volume of the grinding medium is 90% of the volume of the grinding tank, and the grinding medium Use zirconia balls with diameters of 8mm and 6mm respectively, and the volume ratio of the two zirconia balls is 1:1;

[0033] Step 3: Separating the grinding medium by sieving to obtain deacetylated konjac glucomannan.

[0034] The mass percentage of acetyl group in the gained konjac glucomannan is as shown in Table 1, and the infrared analysis spectrogram of gained konjac glucomannan is as follows figure 1 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com