Yarn tension monitoring and setting system

A technology of yarn tension and yarn, which is applied in control/regulation systems, transportation and packaging, textiles and papermaking, etc., and can solve the problem that yarn tension cannot be maintained sufficiently uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

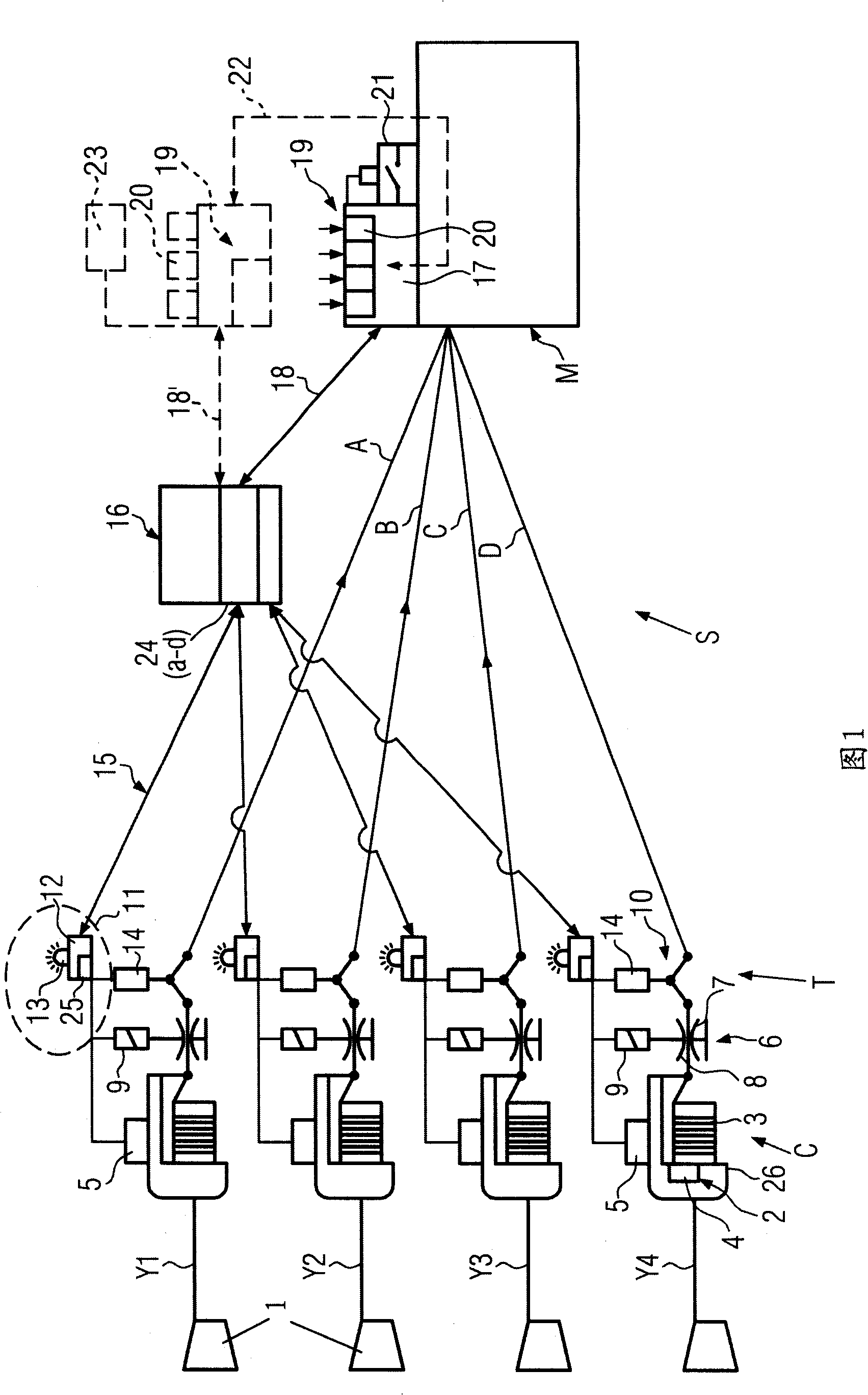

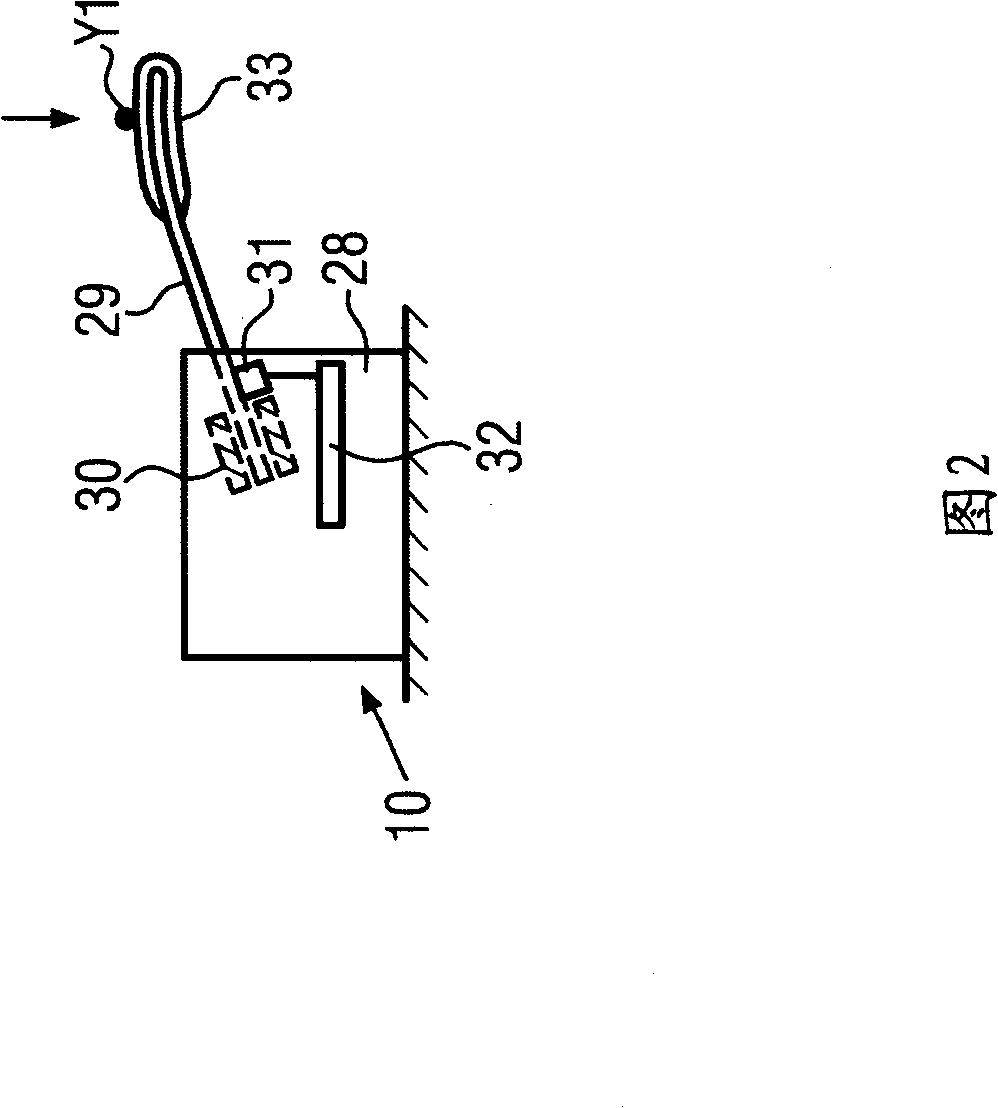

[0028] A yarn processing machine M, such as a yarn twisting machine, a crimper such as an air-jet entangler, or a printing and dyeing machine, simultaneously processes a plurality of yarns Y1 to Y4 (or even more) Separate yarn channels A to D run into a common inlet or into several inlets of the yarn processing machine M. Between eg a series of yarn storage coils 1 and a yarn processing machine M, a yarn delivery device C and a yarn tensioning device T are arranged. The yarn delivery device C is split into a corresponding number of conveyors, each of which corresponds to only a single yarn Y1 to Y4 , such as the yarn feeding device 2 . Each yarn feeding device may be a yarn feeding device normally used for rapier looms or projectile looms. The respective yarn feeding device 2 has a fixed storage drum 3 , an electric motor 4 for driving the winding element 26 and an integrated speed controller 5 .

[0029] Similarly, the thread tensioning device T is split into a correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com