Ink-jet recording medium

A recording medium and inkjet technology, applied in the direction of copying/marking method, printing, printing device, etc., can solve the problems of dirty recording medium, decreased appearance and texture, scratches of recording head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 0.5 parts by weight of epoxidized behenamide, 1.0 parts by weight of anionic polyacrylamide, and 0.1 parts by weight of polyamide polyamine epichlorohydrin are added to 100 parts by weight of LBKP pulp with a beating degree of 300mlcsf in an absolute dry weight ratio relative to the pulp. , 0.5 parts by weight of cationic polyacrylamide to obtain slurry, which is made into 170g / m by fourdrinier paper machine 2 base paper. And, in order to adjust the surface size of the base paper, 0.04% by weight of a fluorescent whitening agent (Sumitomo Chemical Industry, Whitex BB) was added to a 4% aqueous solution of polyvinyl alcohol, and it was soaked into the base paper so that the absolute dry weight converted into 0.5g / m 2 , after drying, further apply calendering treatment to adjust the density to 1.05g / ml to obtain a base paper with a thickness of 150μm.

[0068] After corona discharge treatment is applied to the line surface (back side) side of the base paper obtained in ...

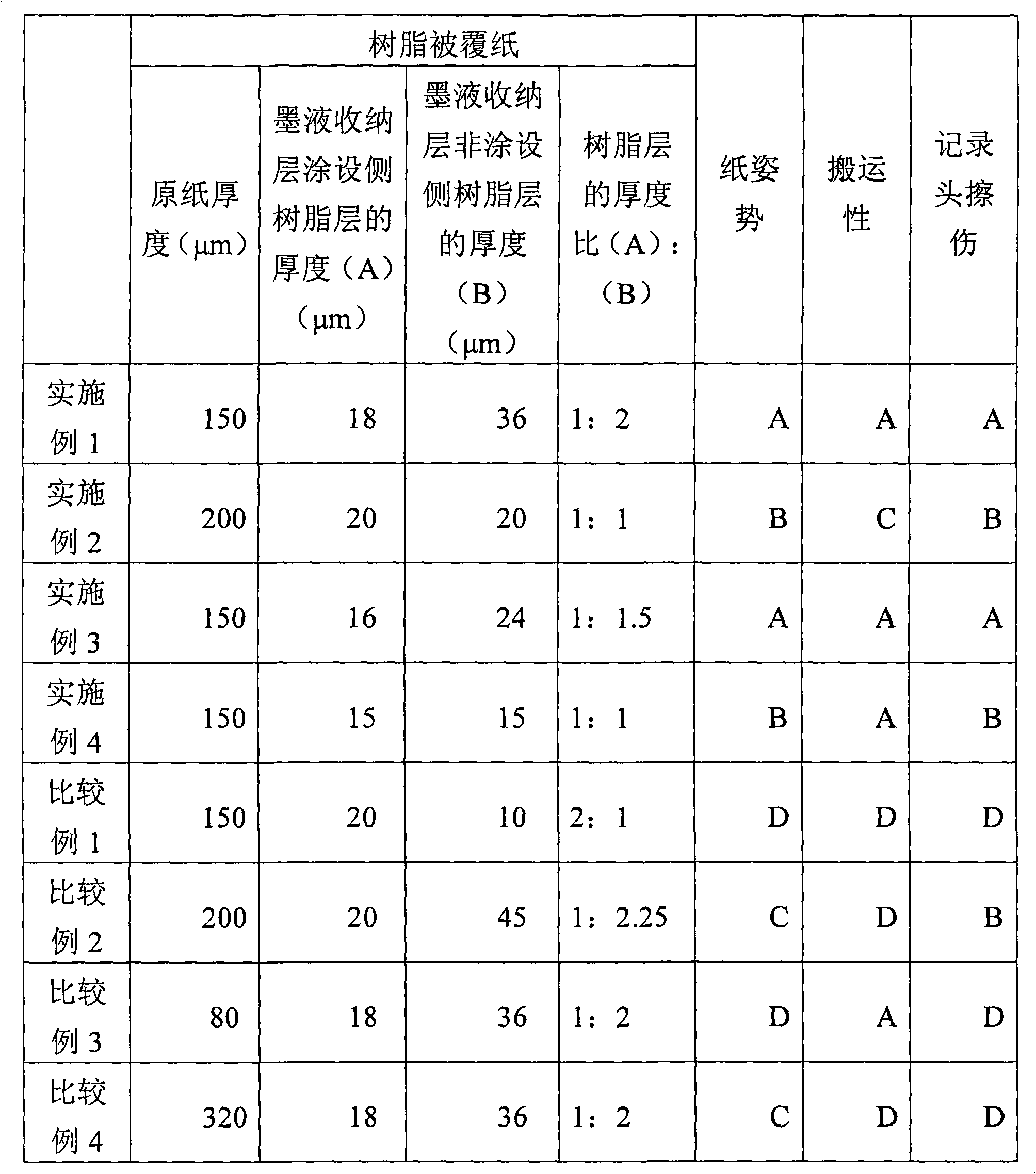

Embodiment 2~4 and comparative example 2~4

[0075] In Example 1, except that the base paper constituting the resin-coated paper and the thickness of the resin layer (resin layer on the ink storage layer coating side, resin layer on the ink storage layer non-coating side) were adjusted as shown in the following (Table 2) Except for various modifications, the same inkjet recording media as in Example 1 were produced, and they were used as samples of Examples 2 to 4 and Comparative Examples 1 to 4, respectively.

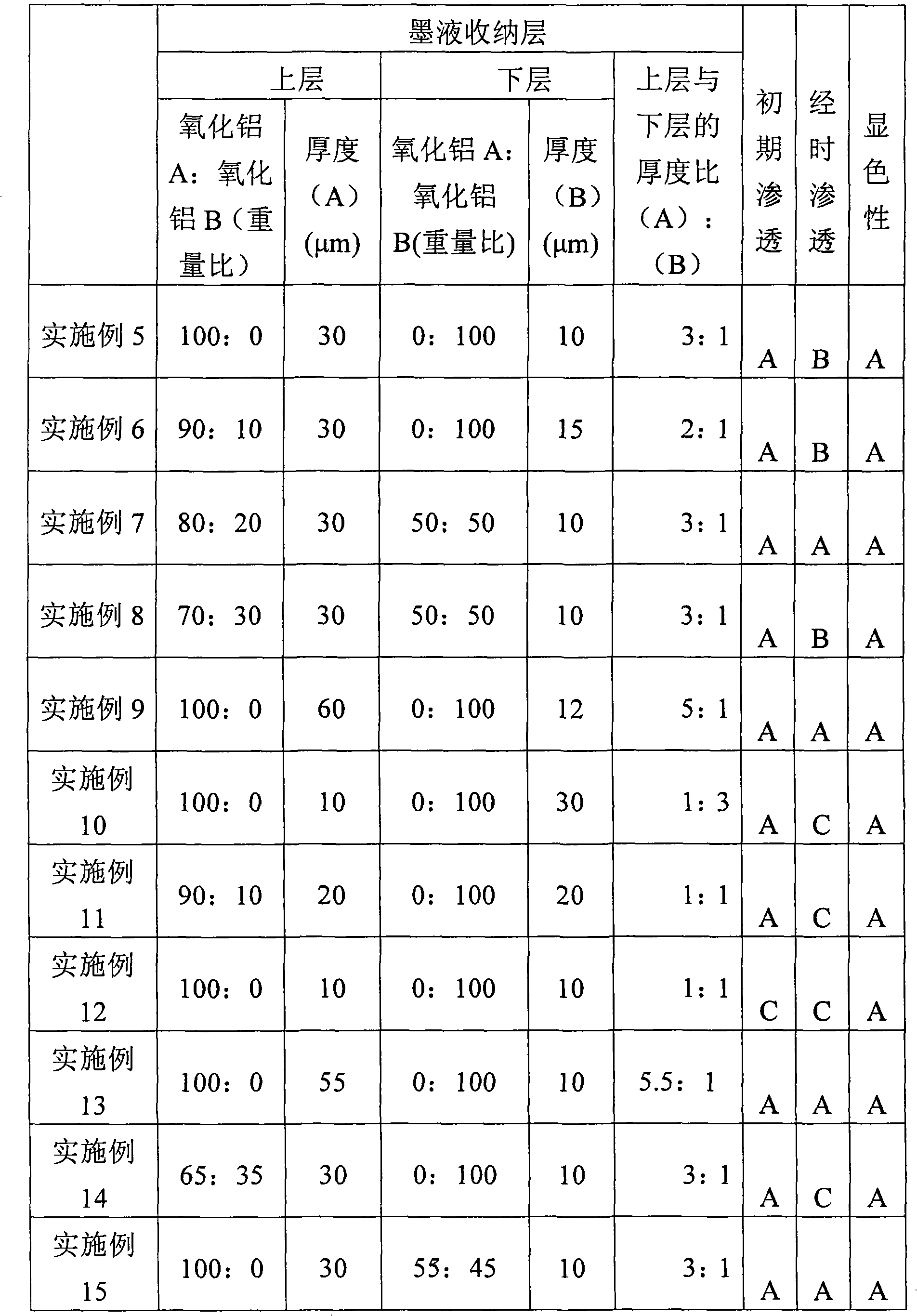

Embodiment 5

[0089] Coating liquids for an upper layer and coating liquids for a lower layer having the following compositions were prepared, respectively. Then, on the above-mentioned anchor coating layer of the resin-coated paper used in Example 1, the coating liquid for the lower layer was coated and dried so that the coating amount after drying was 10 g / m 2 , further, apply and dry the coating liquid for the upper layer, so that the coating amount after drying is 30 g / m 2 . In this manner, an ink storage layer having a two-layer structure composed of a lower layer with a thickness of 10 μm and an upper layer with a thickness of 30 μm laminated in this order was coated on the resin-coated paper.

[0090] The inkjet recording medium obtained by the above procedures was used as a sample of Example 5.

[0091]

[0092]・Alumina A (manufactured by Catalytic Chemicals Co., Ltd., kataroido AS-3) 10% by weight

[0093] (Average primary particle diameter 10μm, average pore radius 3.3nm)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com