Installation method of lifting travel locating optoelectronic control device

A technology of photoelectric control and installation method, which is applied in the direction of non-electric variable control, position/direction control, control/regulation system, etc. It can solve the problem of increased damage rate of travel limit position switch, increased equipment failure rate, and no prompt function, etc. Problems, achieve the effect of reducing mechanical loss, low energy consumption, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

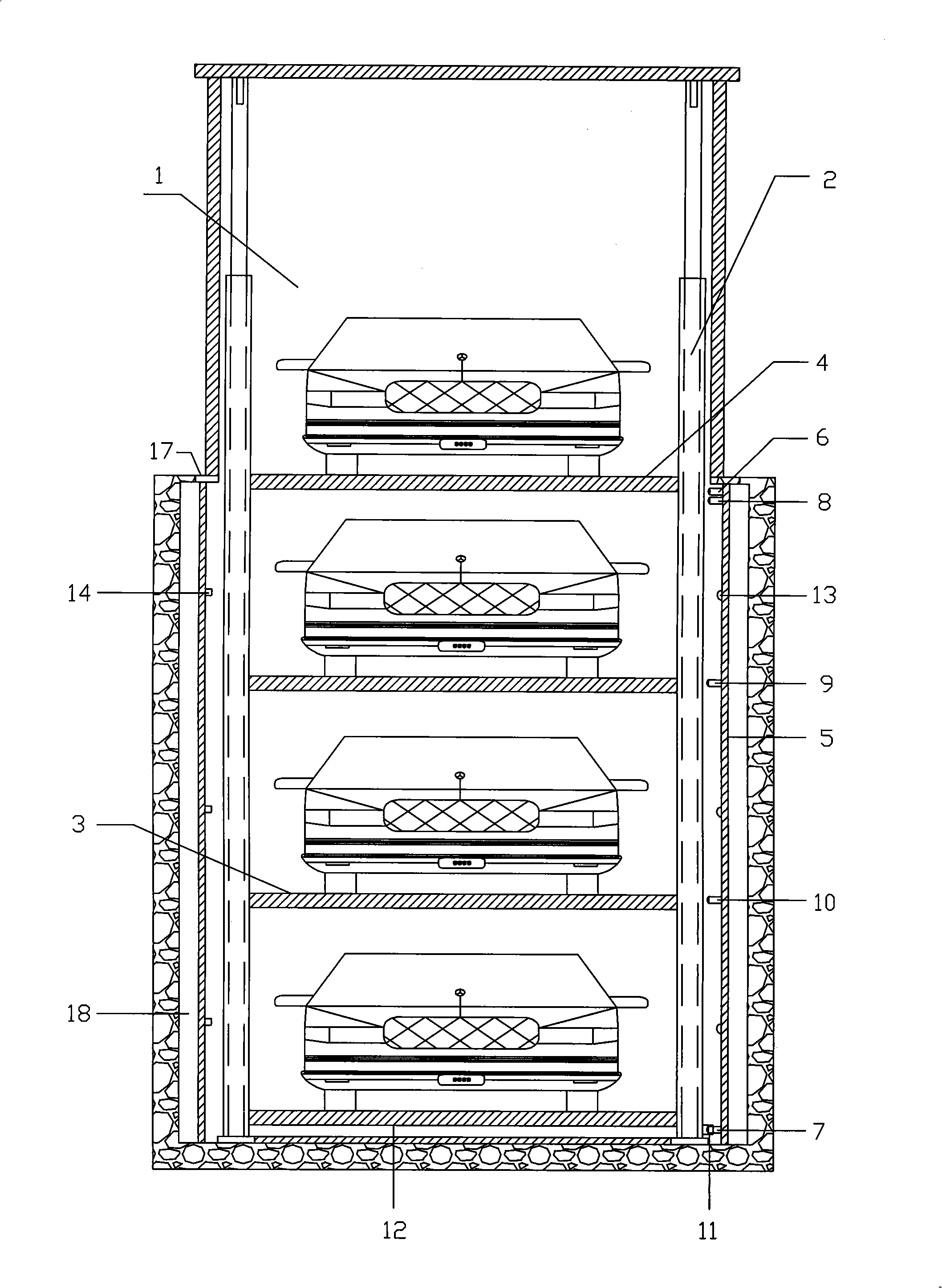

[0022] On the two sides of the three-dimensional vertical lifting parking equipment on the ground floor and underground three floors composed of the parking body 1, the lifting structure body 2, the parking plates 3, and the parking space 4, the two sides of the three-dimensional vertical lifting parking equipment are fixed and installed at the corresponding positions. The upper limit U-shaped photoelectric sensor 6 is installed on the upper side of the functional column 5 corresponding to the ground parking plate 3; the limit positioning U-shaped photoelectric sensor 8 is installed below; the limit positioning is installed at the position corresponding to the lower parking plate 3 U-shaped photoelectric sensor two 9; then install the limit positioning U-shaped photoelectric sensor three 10 at the corresponding position of the lower parking plate; install the lower limit positioning U-shaped photoelectric sensor 7 at the corresponding position under the frame of the bottom parking...

Embodiment 2

[0029]On the two sides of the three-dimensional vertical lifting parking equipment on the ground floor and the underground two floors composed of the parking body 1, the lifting structure body 2, the parking plates 3, and the parking space 4, the two sides of the three-dimensional vertical lifting parking equipment are fixed and installed to stand 5, one The upper limit U-shaped photoelectric sensor 6 is installed on the upper side of the functional column 5 corresponding to the ground parking plate 3; the limit positioning U-shaped photoelectric sensor 8 is installed below; the limit positioning is installed at the position corresponding to the lower parking plate 3 U-shaped photoelectric sensor 2 9; A lower limit positioning U-shaped photoelectric sensor 7 is installed at the corresponding position under the frame of the bottom parking plate 12. Vacancy detection photoelectric sensor transmitters 13 are respectively installed between the two parking panels 3 at positions corresp...

Embodiment 3

[0035] On both sides of the three-dimensional vertical lifting parking equipment on the ground floor and underground floor composed of the parking body 1, the lifting structure body 2, the parking plates 3, and the parking spaces 4, the two sides of the three-dimensional vertical lifting parking equipment corresponding to each other are fixed and installed. The upper limit U-shaped photoelectric sensor 6 is installed on the functional column 5 on the side corresponding to the ground parking plate 3; the limit positioning U-shaped photoelectric sensor 8 is installed below; the lower is installed at the corresponding position under the frame of the bottom parking board 12 Limit positioning U-shaped photoelectric sensor 7. Vacancy detection photoelectric sensor transmitters 13 are respectively installed between the two parking panels 3 at positions corresponding to the car body of the parking space 4; Vacancy detection photoelectric sensor receivers 14 are respectively installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com