Ball hinge device based on flexible member

A technology of flexible components and spherical hinges, which is applied in the field of positioning support and connection mechanisms, can solve the problems that the degree of freedom of rotation is not easy to realize, affect the stiffness of flexible hinges, the range of motion and life, and the torsional stiffness of the constricted part is large, and the principle is clear. , simple structure, loose processing and installation process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

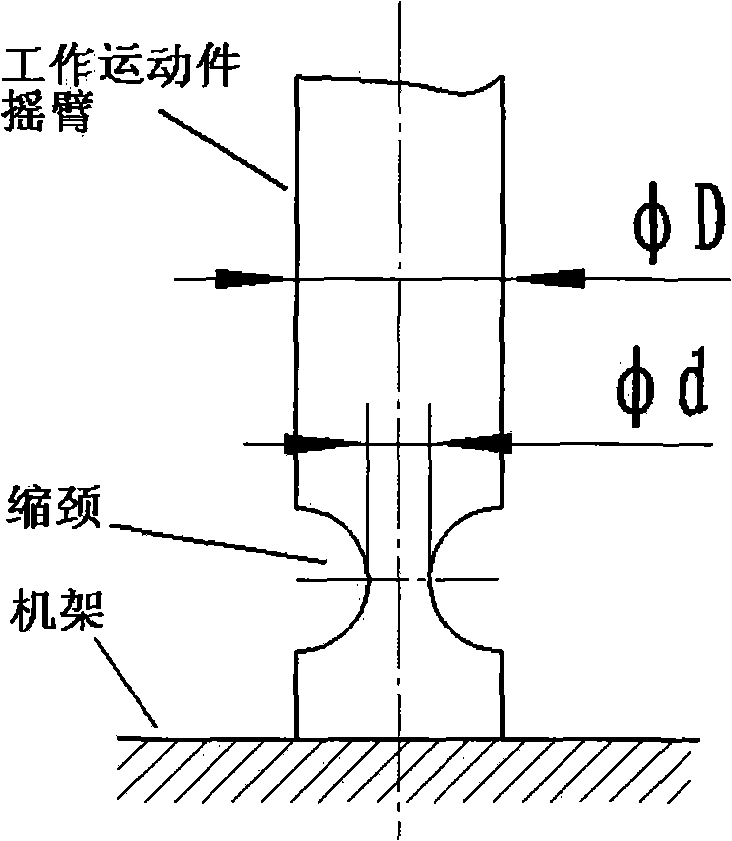

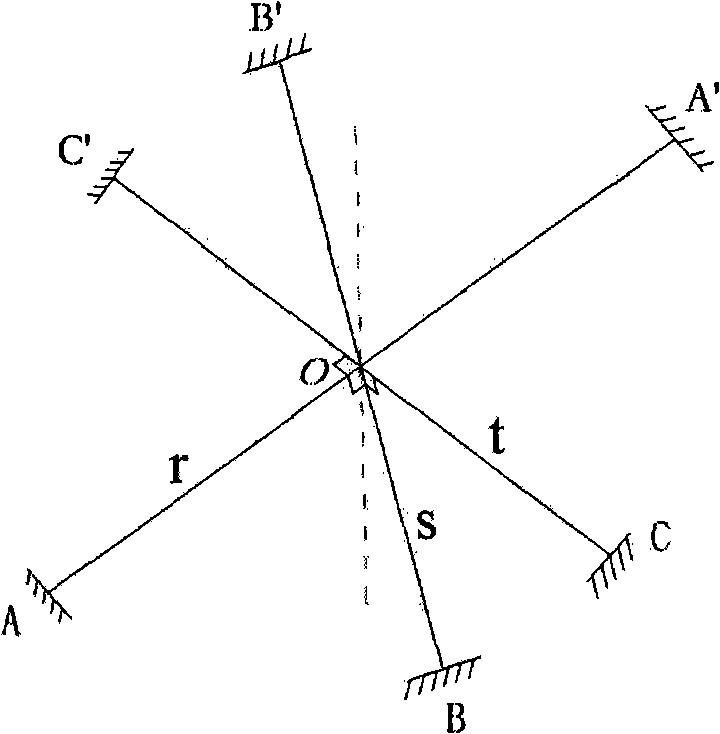

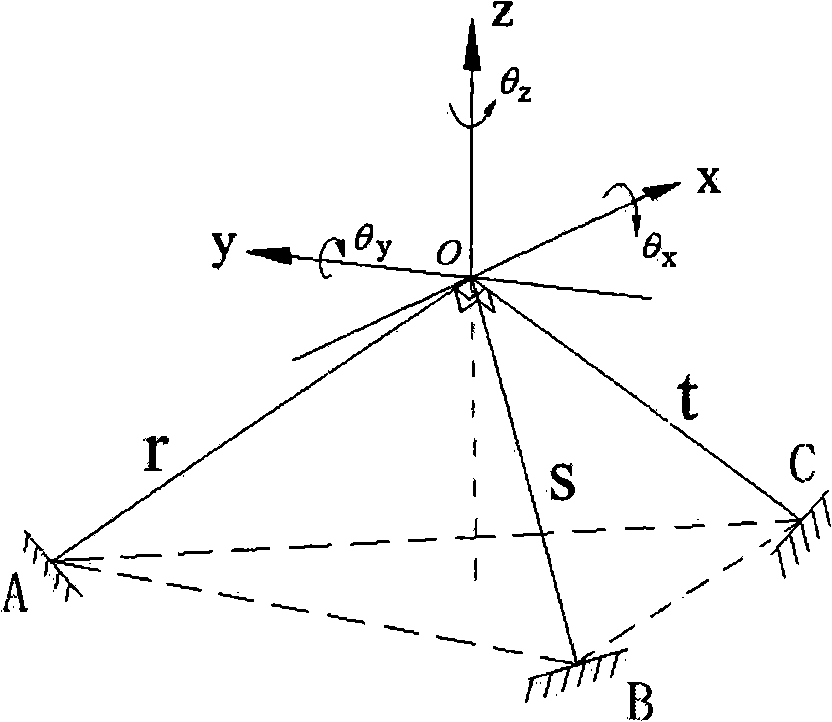

[0045] Embodiment 1, the ball hinge mechanism based on flexible elements see Image 6 , Figure 7 , Figure 8 , three through holes slightly larger than the steel wire 4 are drilled orthogonally on the ball joint 6, and the center is drilled with a hollow as large as possible so that the three steel wires 4 (the third vertical paper surface) can pass through, and the moving parts are connected by threads rocker arm 1. In order to eliminate the gap and maintain stability, after the three steel wires 4 pass through the corresponding small holes on the ball joint 6, the steel wires 4 and the corresponding holes on the ball joint 6 are filled tightly by brazing. Then, move the rocker arm 1 through the middle hole of the upper pressing plate 2 . The size of the hollow of the upper pressing plate 2 is designed according to the angle range that the ball joint needs to work, so as to prevent the moving part rocker arm 2 from exceeding the working angle orientation, thereby causing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com