Safety alarm device for flat knitting machine

A safety alarm device and the technology of knitting flat knitting machines, which are applied in knitting, textiles and papermaking, etc., can solve the problems of inability to generate alarms, affect the performance of fabric weaving machines, and achieve the effect of improving weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

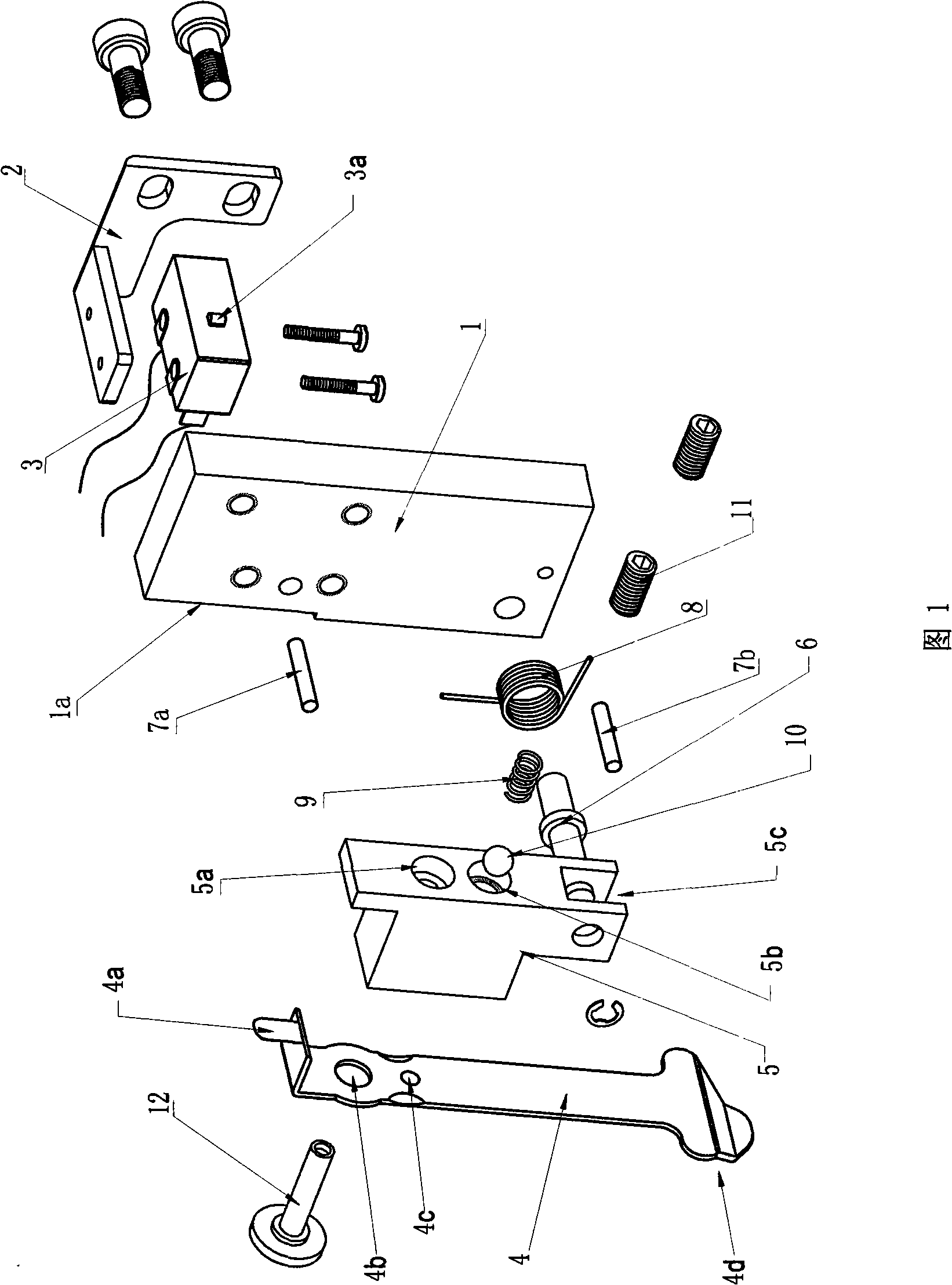

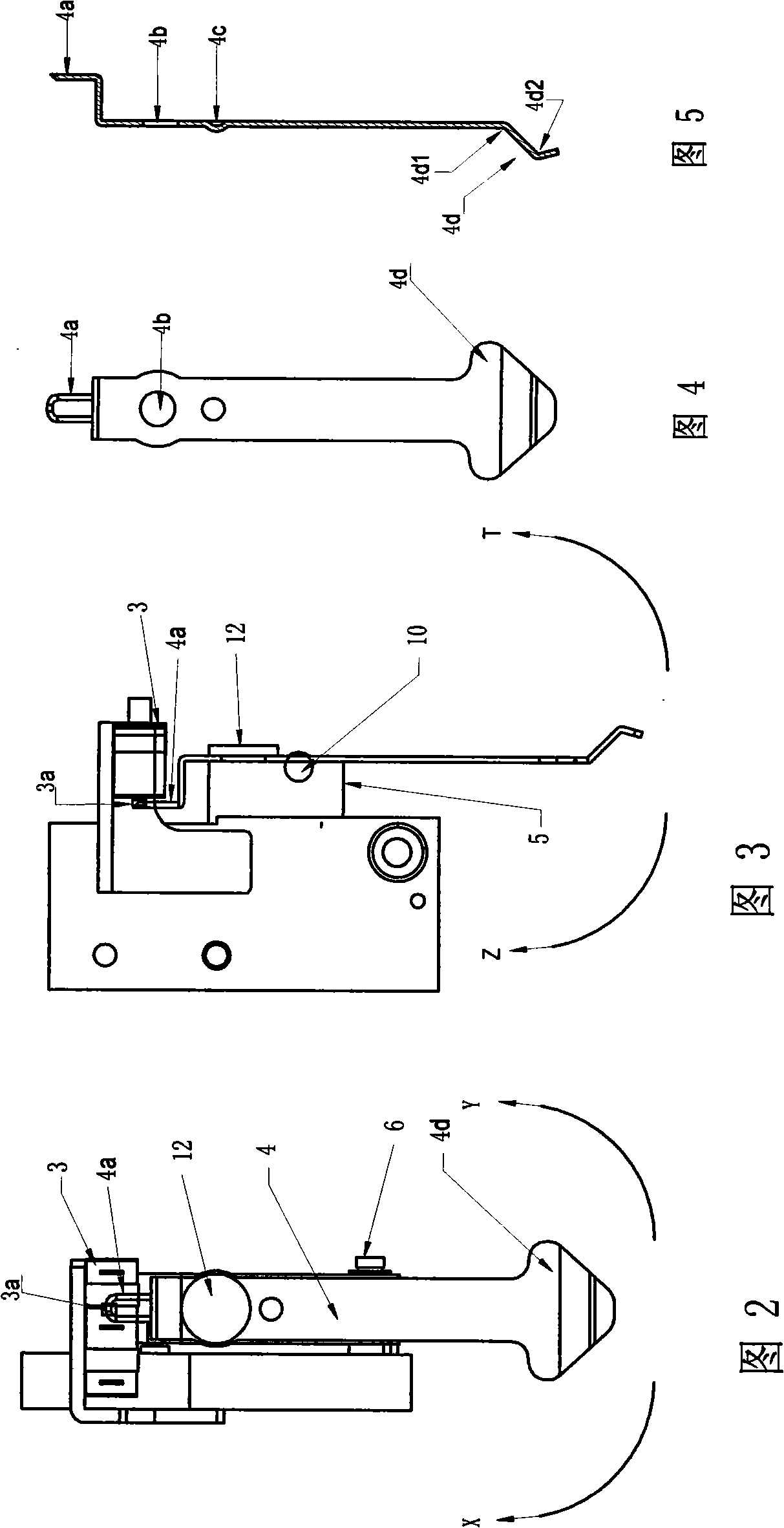

[0017] As shown in Figure 1, Figure 2, and Figure 3, the upper end of the probe base 1 is equipped with a micro switch base 2, and the micro switch 3 is fixed on the micro switch base 2 and placed on the front of the probe base 1. The contacts 3a on the top face the front side 1a of the probe holder. Two limit pins are provided on the side of the probe base, namely the first limit pin 7a and the second limit pin 7b.

[0018] The lower end of the probe holder 5 is provided with a slot 5c, and a torsion spring 8 is installed in the slot 5c, and the rotating shaft 6 passes through the torsion spring 8 to rotatably connect the probe holder 5 to the lower end side of the probe holder 1 . Both ends of the torsion spring 8 are fixed on the probe base through the first limiting pin 7a and the second limiting pin 7b. In this way, the probe frame 5 can swing up and down relative to the probe holder, that is, it can swing along the Z and T directions. Due to the limiting effect of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com