Automatic assembling machine of accurate connector

An automatic assembly machine and connector technology, which is applied in the assembly/disassembly of contacts, etc., can solve the problems of low production efficiency, large consumption of human resources, and high probability of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

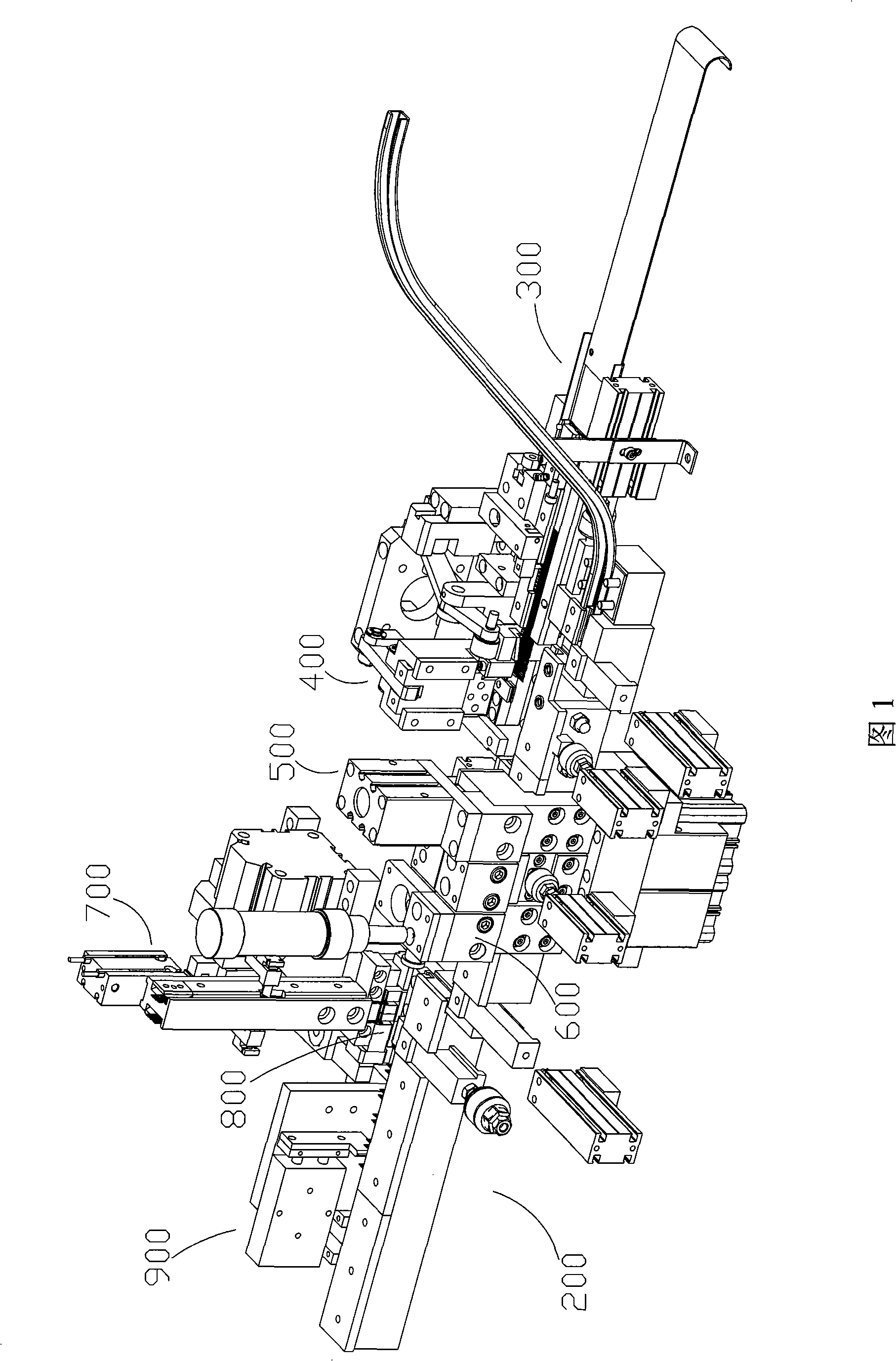

[0103] A precision connector automatic assembly machine, including

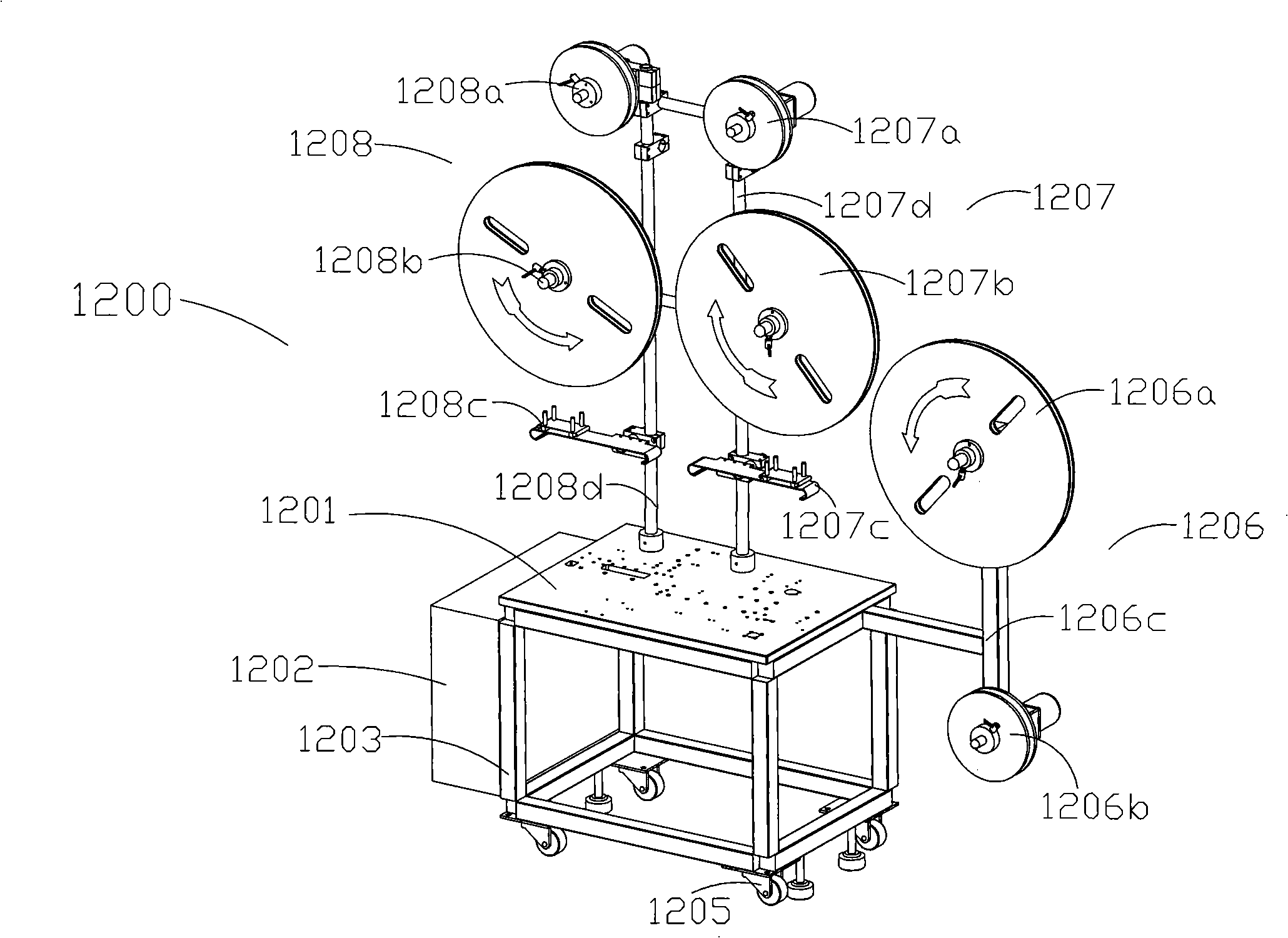

[0104] Such as figure 2 The shown feeding station device 1200 includes

[0105] The support frame 1203 has a bottom plate 1201, and an electric control box 1202 is installed on one side of the support frame 1203; in addition, a caster assembly 1205 is installed at the bottom of the support frame, so that the entire support frame 1203 can be moved conveniently.

[0106] The terminal feeding assembly 1206 includes a terminal feeding assembly bracket 1206c arranged on one end surface of the bottom plate 1201; a first terminal feeding motor and a terminal feeding tray 1206a connected thereto, both of which are installed at one end of the terminal feeding assembly bracket 1206c; the second terminal The feeding motor and the terminal tray 1206b connected thereto are installed at the other end of the terminal feeding assembly bracket 1206c; the controllers of the first terminal feeding motor and the second terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com