Return pull-type decorticating machine

A hemp peeling machine and a technology of hemp peeling, which are applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve problems affecting the quality of hemp peeling, unreasonable angle setting, and low efficiency of hemp peeling, so as to improve labor efficiency and machine utilization rate, avoiding too long residence time, and improving the quality of peeling hemp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

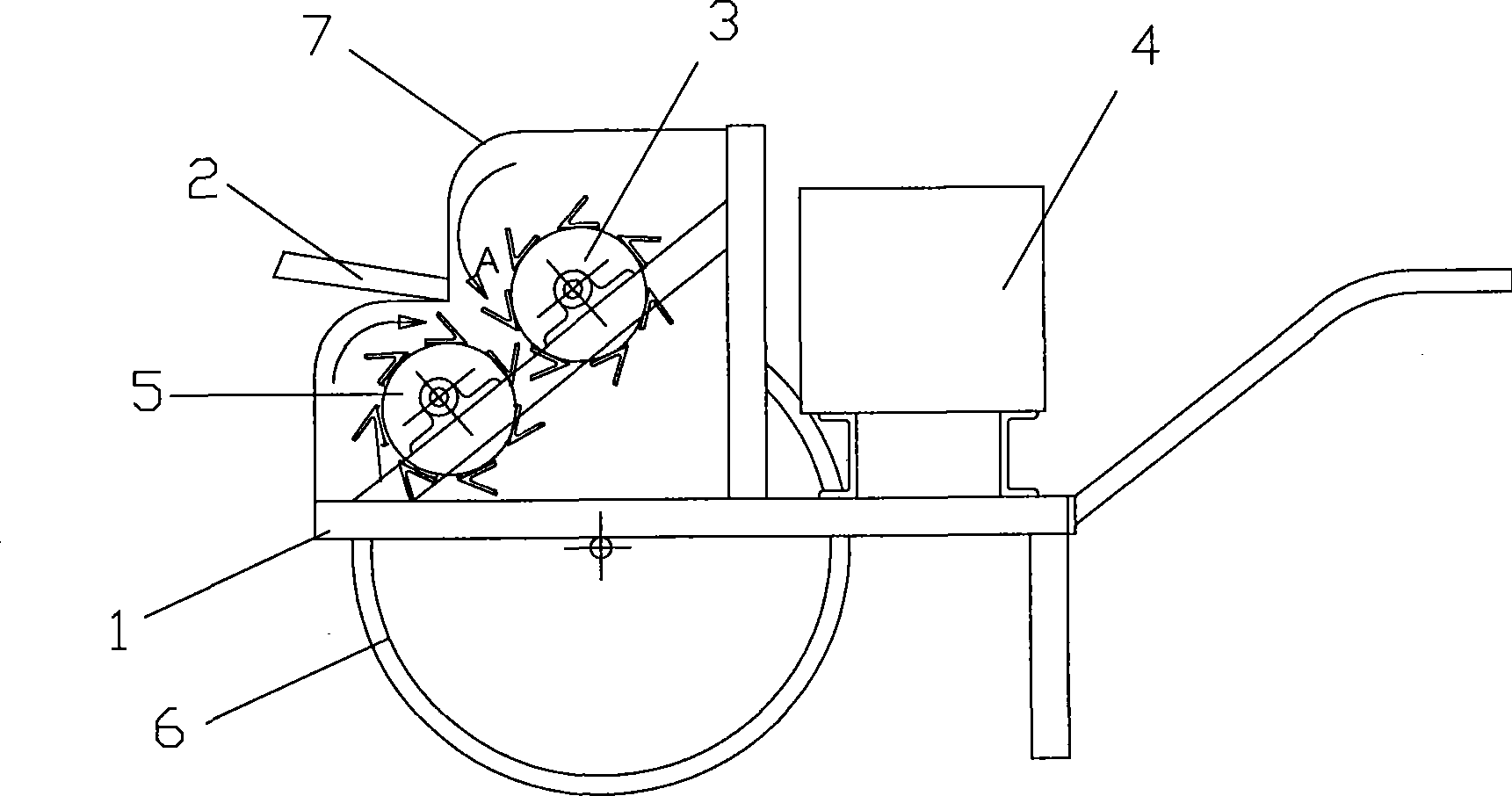

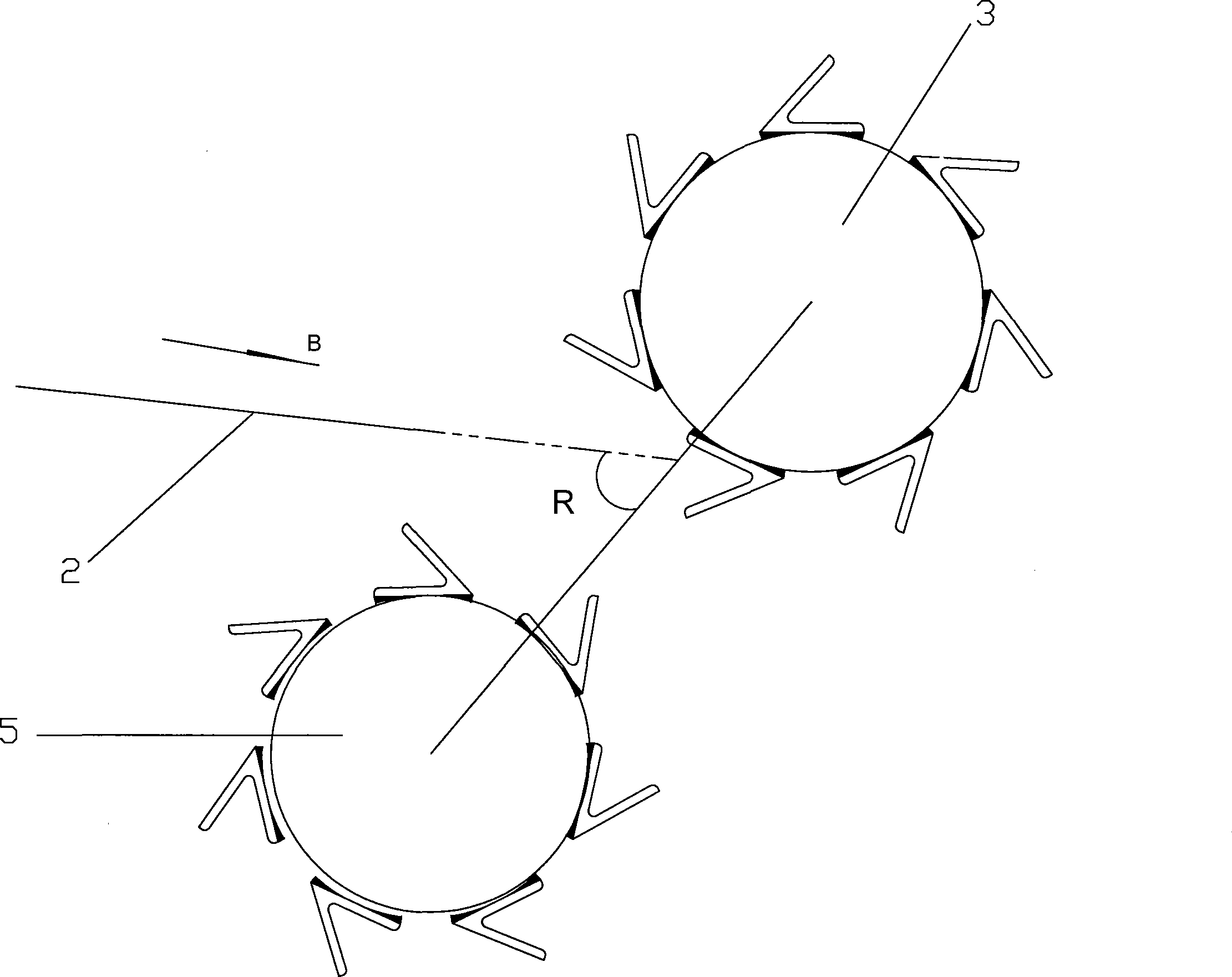

[0021] Such as figure 1 As shown, the pull-back type stripping machine of the present embodiment mainly consists of a frame 1, a linen feeding channel 2 installed on the frame 1, an active stripping roller 3 and a passive stripping roller 5 for The power unit 4 that drives the active stripping roller 3, in this embodiment, the power unit 4 is a 3.2 kilowatt (kW) air-cooled diesel engine. The included angle R between the line connecting the active hemp-stripping roller 3 and the passive hemp-stripping roller 5 axes and the hemp feeding channel 2 is 45°.

[0022] When the hemp stripping machine is working, the hemp is fed along the hemp feeding channel 2, because the angle R between the axis of the active stripping roller 3 and the passive stripping roller 5 and the hemp feeding channel 2 is 45 °, so that the hemp enters the hemp stripping machine at an appropriate speed, and prevents the hemp from entering the hemp stripping machine too fast under the action of two stripping r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com