Method for preparing anti-freezing deicing salt

A snow-melting agent and anti-freezing technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of short-term snow-melting effect, achieve the effect of improving snow-melting effect, easy removal, and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

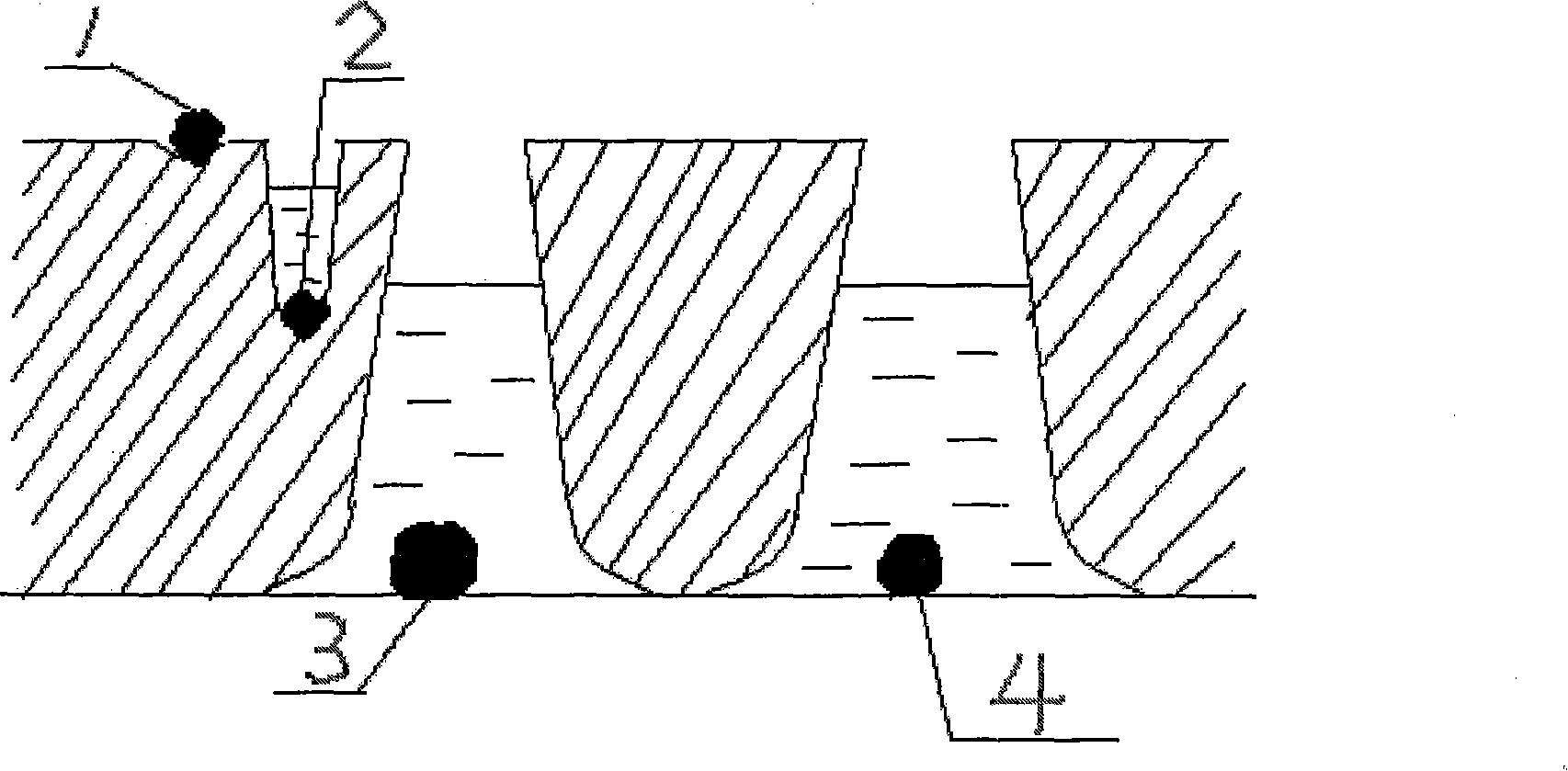

Image

Examples

example 1

[0020] Example 1: Magnesium chloride, calcium chloride, and potassium chloride are made into a saturated solution at 20°C with a molar ratio of 7:2:1. The sign of becoming the desired saturated solution is that a small amount of solid exists in the solution. Soak sepiolite between 10 mesh and 80 mesh for 15 minutes, filter off the solution, dry the sepiolite particles at 120°C, and then go through a process of soaking-filtering-off-drying to produce antifreeze type Deicing agent.

example 2

[0021] Example 2: Make calcium magnesium acetate (CMA) into a saturated solution at 100°C. The sign of becoming the desired saturated solution is that a small amount of solid exists in the solution. Add diatomaceous earth with a particle size between 10 mesh and 80 mesh Soak for 45 minutes, filter off the solution, and then dry at 105°C to constant weight. After 5 cycles of soaking-filtering-drying, the anti-freeze deicing agent can be prepared.

example 3

[0022] Example 3: Calcium magnesium acetate (CMA) and potassium dihydrogen phosphate are made into a saturated solution at 80°C with a mass ratio of 8:2. The sign of becoming the desired saturated solution is that a small amount of solid exists in the solution. Soak in zeolite between 10 mesh and 80 mesh for 30 minutes, filter off the solution, and then dry it at 110°C to constant weight. After four cycles of soaking-filtering-drying, the antifreeze type can be obtained Deicing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com