High-speed area array camera shafting traverse vibration measuring apparatus and method thereof

A technology of measuring device and measuring method, which is applied to the measurement of shafting lateral vibration and the field of measuring device of shafting lateral vibration, which can solve the problems of small spatial measurement range and achieve the effect of low uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

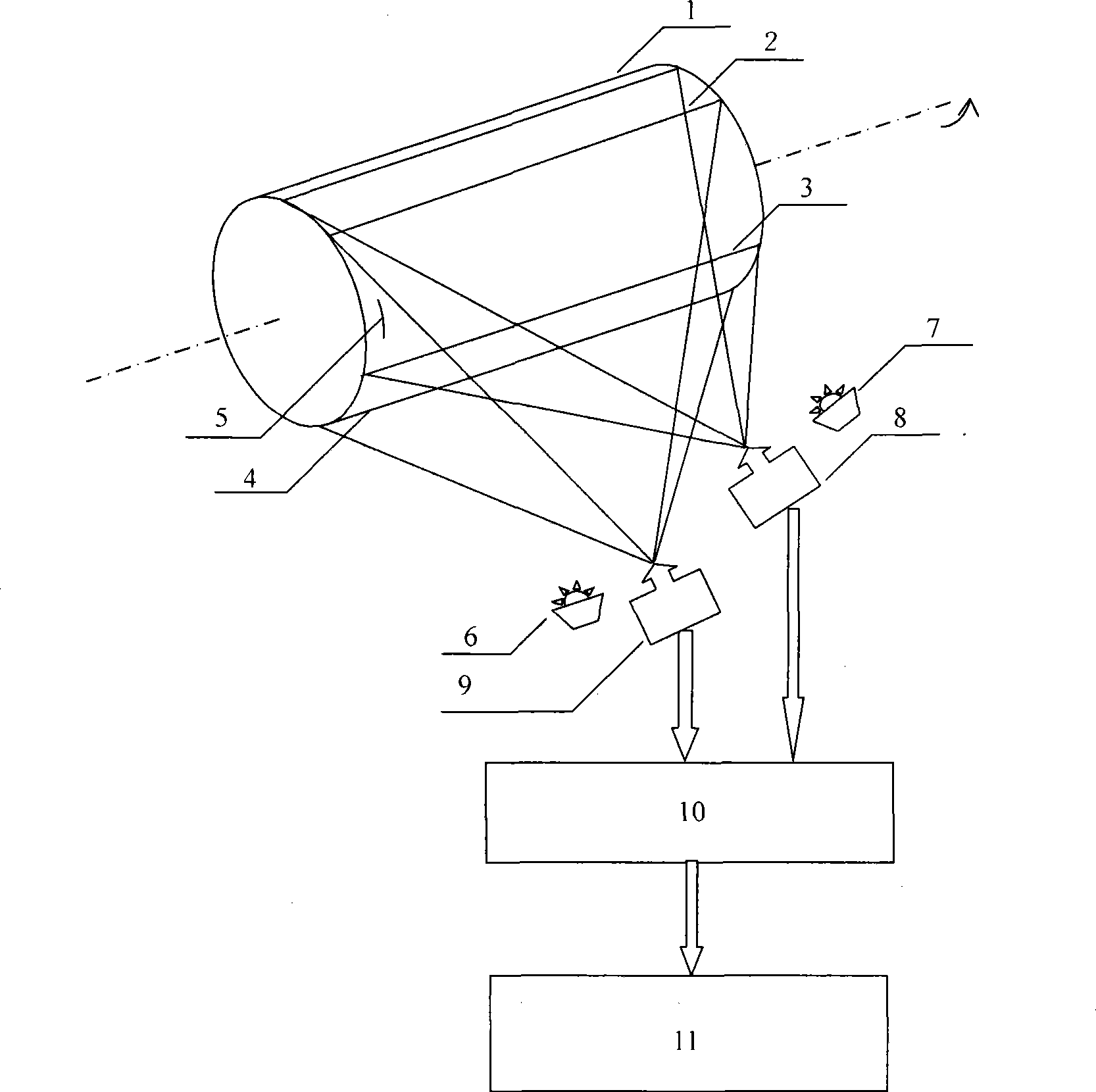

[0023] combine figure 1 , the high-speed area array camera axial vibration measurement device includes: an initial mark (5) arranged in the common field of view of the two high-speed area array cameras on the measured axis, in the same vertical plane, the main optical axes of which are mutually fixed Angle of two high-speed area array cameras, i.e. high-speed area array CCD camera I (8) and high-speed area array CCD camera II (9), and light source I (7) and light source II ( 6), the two high-speed area array cameras are aimed at the same section of the measured axis and roughly parallel to the measured axis, and the two high-speed area array cameras are connected to the data processing and control unit (10) and the human-computer interaction interface (11). The main optical axes of the two high-speed area array cameras form a certain angle with each other within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com