Anti-explosion bottle cap of thermos bottle

A thermos and bottle cap technology, applied in the directions of bottle/container cap, bottle filling, sealing plug, etc., can solve the problem of air pressure rise, and achieve the effect of reducing air pressure difference, simple structure, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

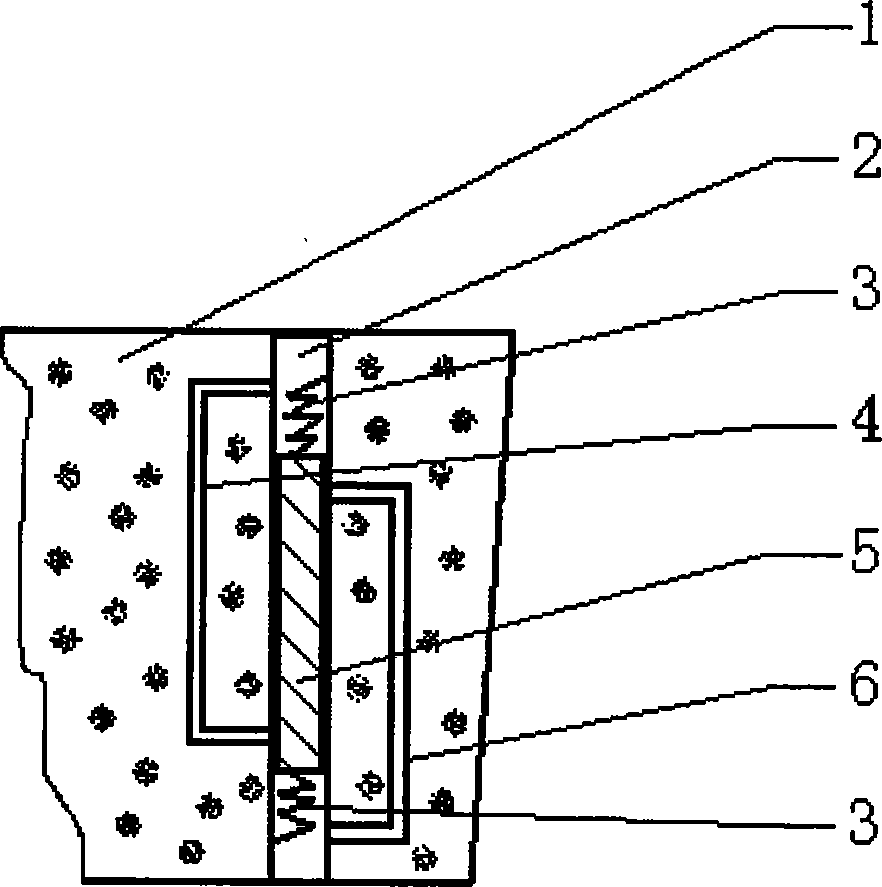

[0010] The thermos explosion-proof bottle cap that the present invention provides except bottle cap 1, also has vent hole 2 and decompression valve, and wherein, vent hole 2 is positioned at bottle cap 1, and runs through bottle cap 1 up and down; 5. Return spring 3, air outlet 4, and air inlet 6 are composed; piston 5 is located in vent hole 2; there are two return springs 3, one end is fixed on the inner wall of vent hole 2, and the other end is connected to the top and bottom of piston 5 respectively. The lower end; the air outlet hole 4 and the air inlet hole 6 are located on both sides of the air hole 2 in the bottle cap 1 and communicate with the wall of the air hole 2 . When the present invention is used, when the air pressure in the thermos bottle rises, the pressure difference pushes the piston 5 to rise, and the air outlet 4 penetrates and exhausts, so that the air pressure difference in the thermos bottle decreases; when the air pressure in the thermos bottle decreas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com