Dispensing order automated sorting, grouping and goods-distribution process

A production process and order technology, which is applied in the field of automatic sorting of distribution orders, group order distribution production process, can solve the problems of high cost, complex system, unsuitable equipment promotion and application, etc., and achieves high work efficiency and low distribution production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

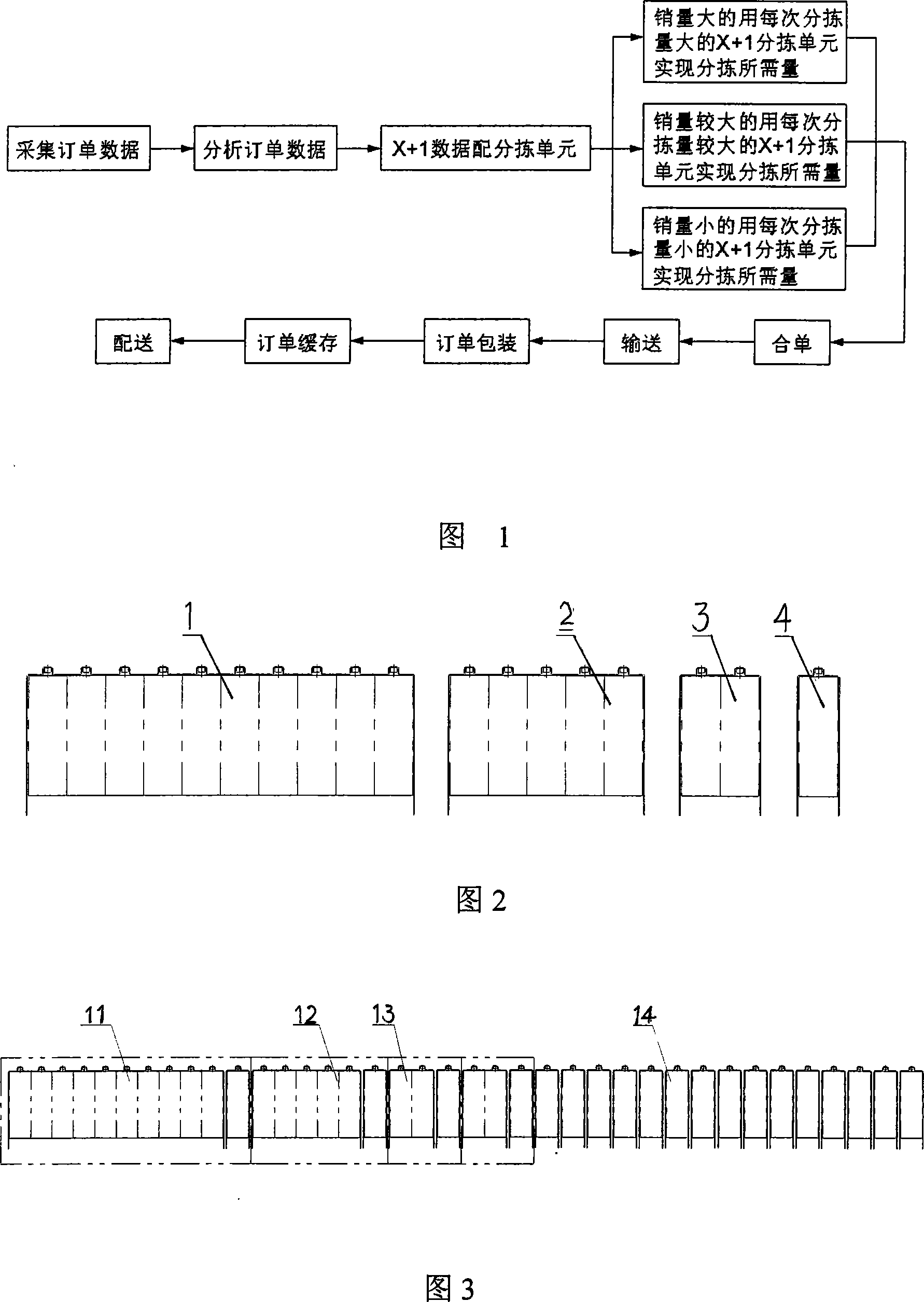

[0027] Figure 1 shows the process flow of the patent of the present invention: after the number of commodity orders is collected, they are processed and sorted, and different X+1 sorting units undertake the sorting task. Generally, the commodities with the largest sales volume are sorted by each The X+1 sorting unit with a large volume is sorted, the products with large sales volume are sorted with the X+1 sorting unit with a large sorting volume each time, and the products with small sales volume are sorted with the X+1 sorting unit (In most cases, single-item sorting unit is used for processing), automatic control, and the sorted quantity is sequentially injected into the order-merging conveyor to carry out the order-merging process, and then carry out subsequent processes such as transportation, order packaging, order buffering, and distribution. .

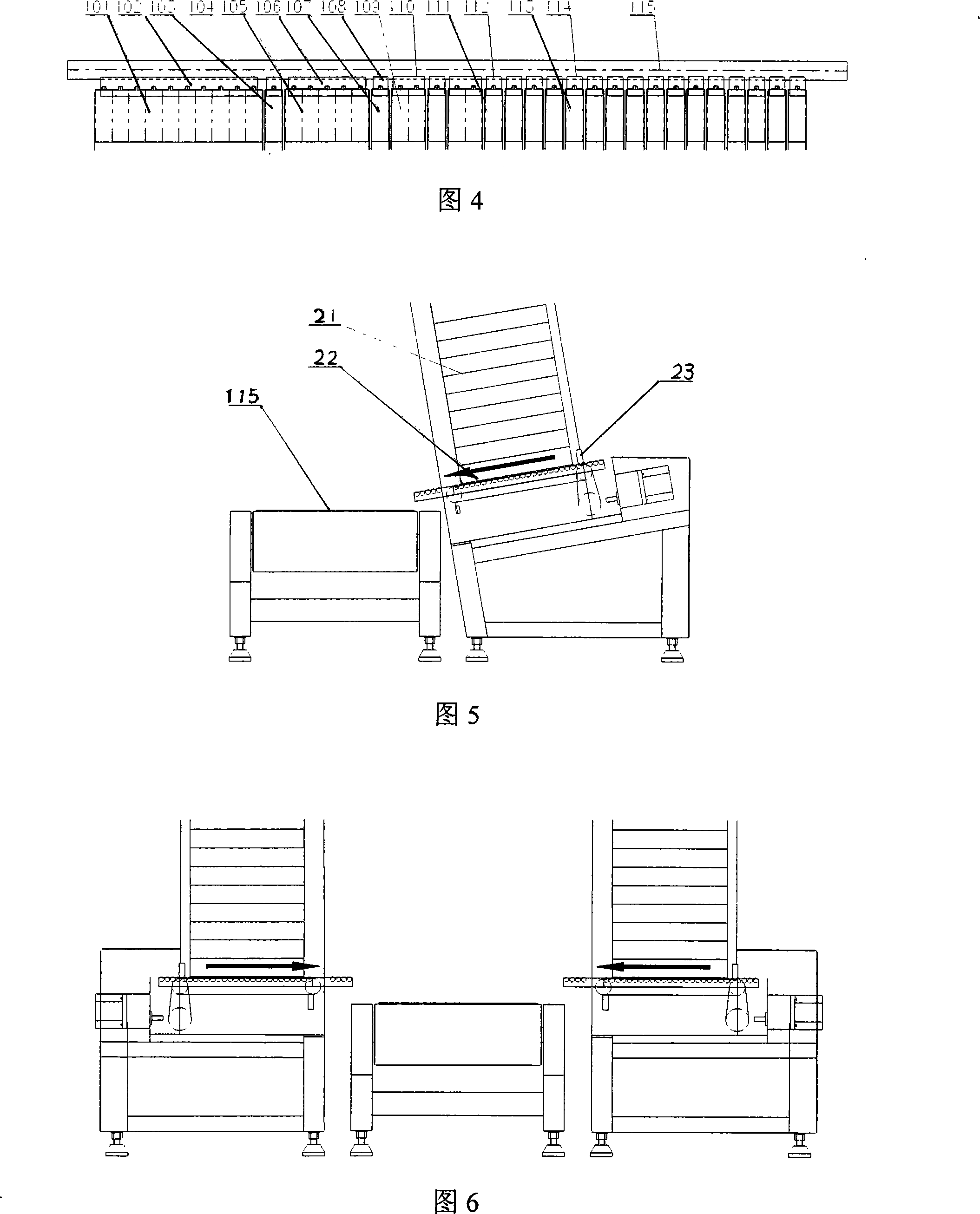

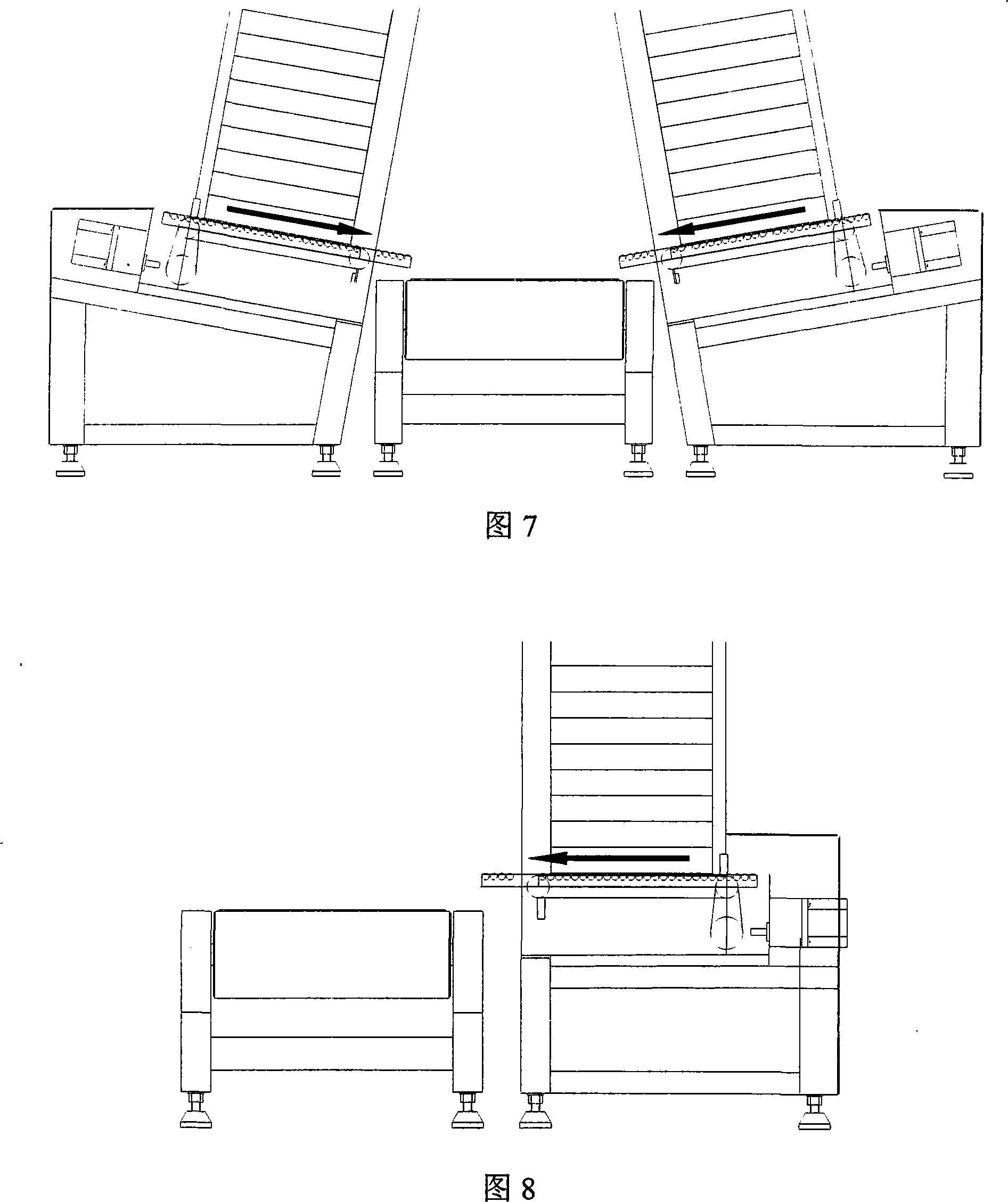

[0028] As shown in Fig. 2-Fig. 3, the distribution order automatic sorting group order distribution production process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com