Spiral gunlock device

A locking mechanism and bolt technology, which is applied in breech mechanism, weapon accessories, offensive equipment, etc., can solve the problems of sealing effect, simplicity, choice and incompatibility of bolt and bolt, and achieve the effect of simple structure, good effect, and improved shooting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

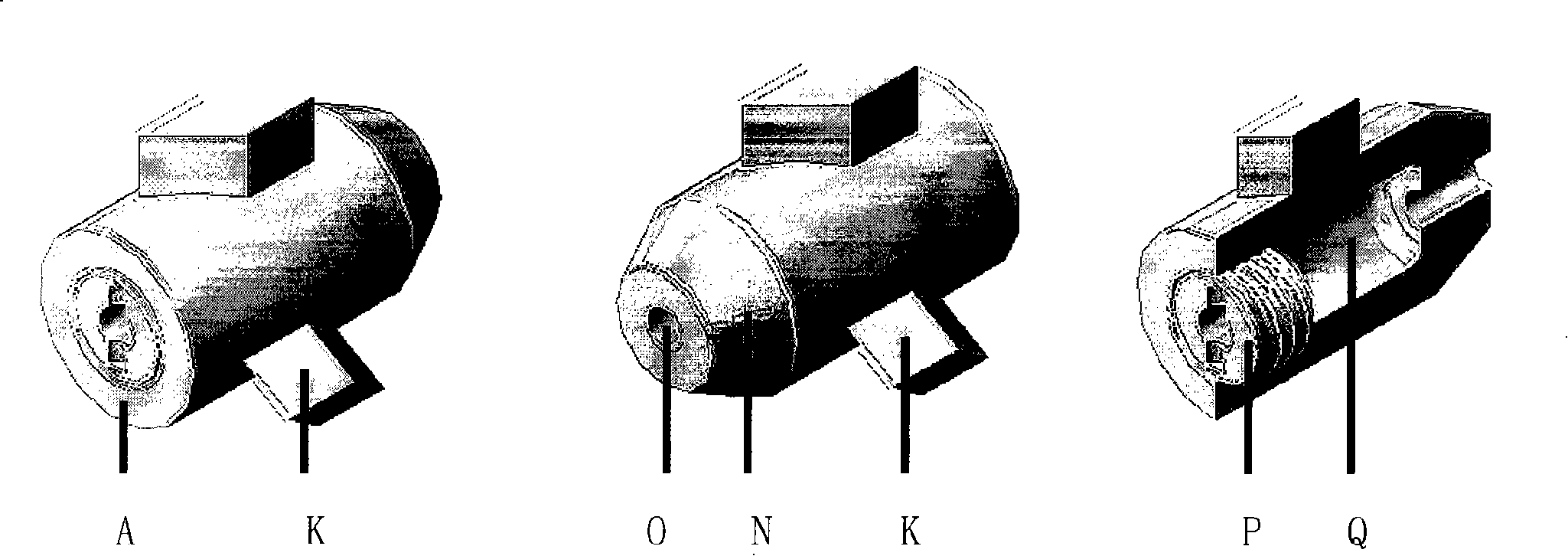

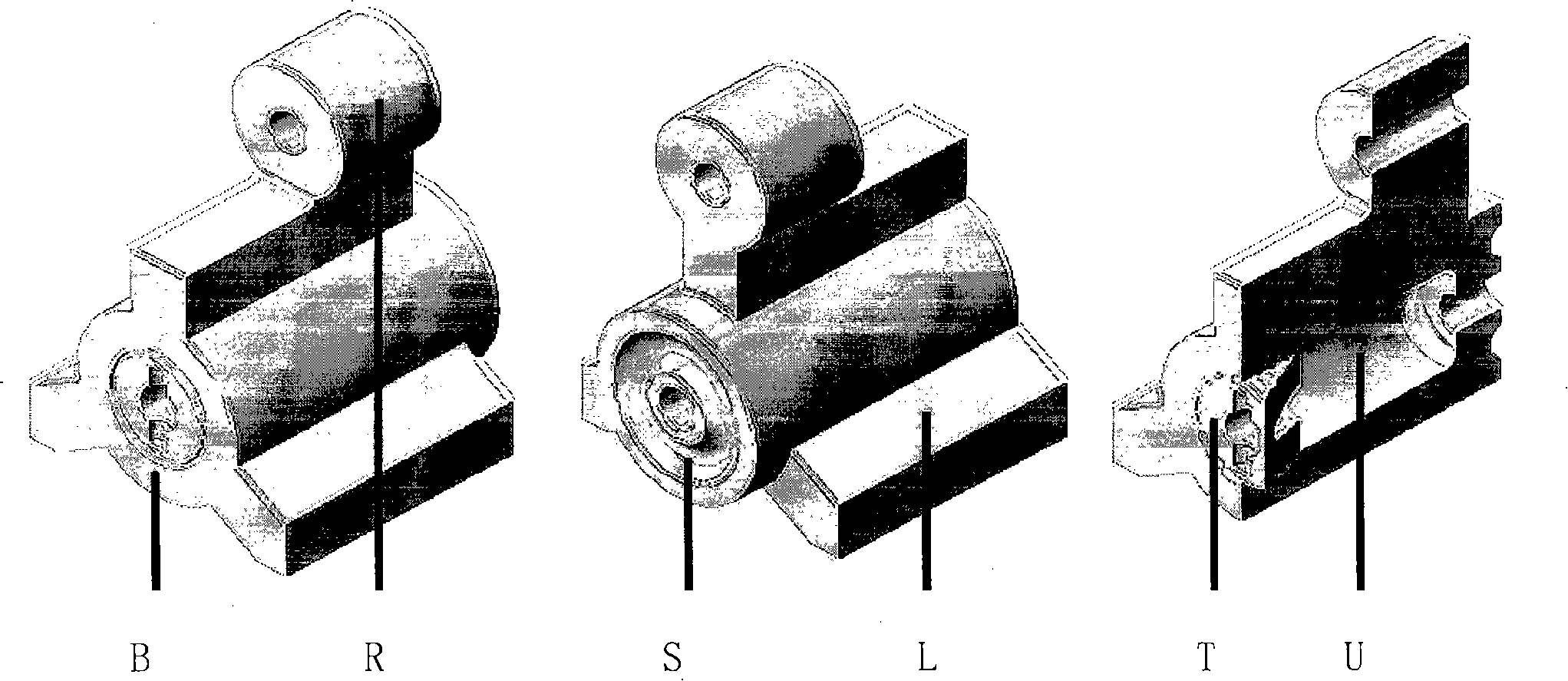

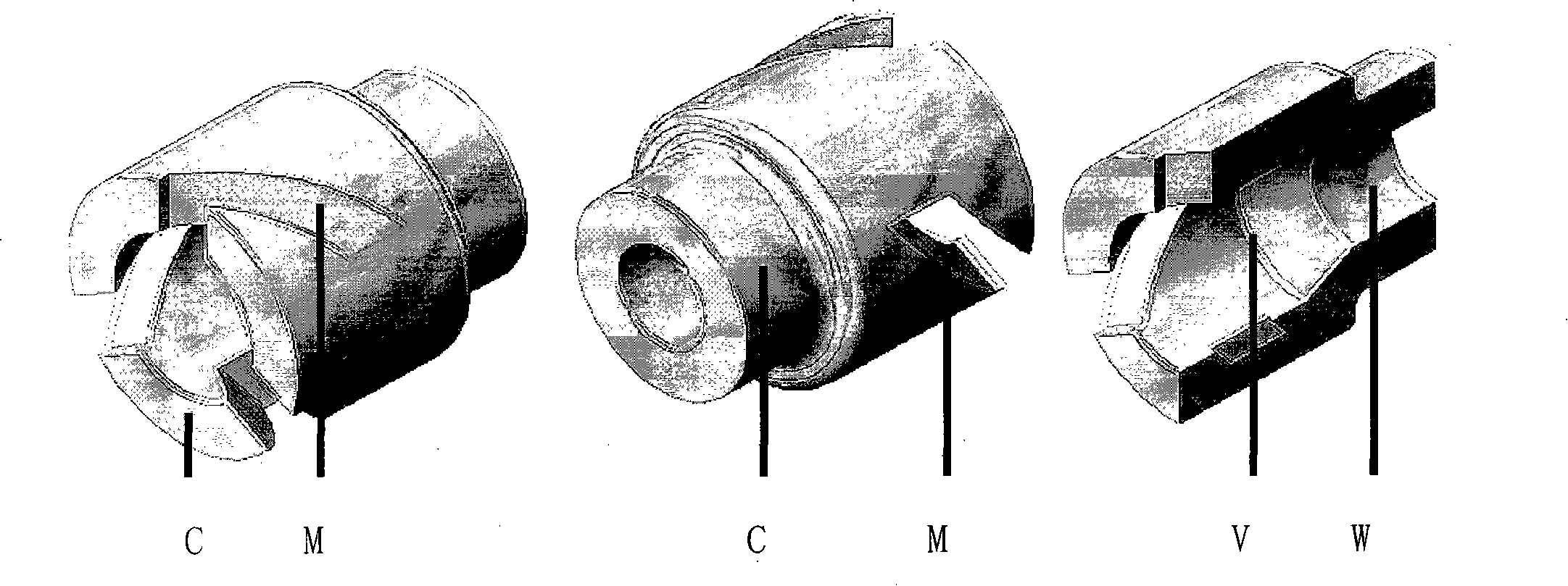

[0046] When the first round is loaded, the charging handle E is pulled, the charging handle E forces the bolt seat B to move backward, the bolt seat B moves back through the striker D and the striker spring G together with the bolt A, and the bolt is unlocked (attached Figure 5 ). The gun bolt overwhelms the hammer and pulls the bullet bar to pull the ammunition out of the magazine. Let go of the charging handle, the recoil spring F works to push the bolt back, and the bolt A pushes the ammunition removed from the magazine into the chamber, and at the same time, it should be guided by the guide groove M of the barrel assembly to rotate and lock (attached Figure 8). The hammer hits the firing pin D to trigger the ammunition. Instantaneously due to the "Bushley's Law" the bolt A sticks to the barrel assembly C, and the breech pressure drops, the bolt A and the barrel assembly C move relative to each other, and the bolt unlocks. Compared with the first round of unlocking, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com