Suction disc vacuum pumping method for smoothing interlining wall, container wall

A technology for vacuuming and container walls, applied in the direction of control valves, functional valve types, engine components, etc., can solve the problems of obstructing tailpipes, detachable vacuum body vacuuming process complexity, etc., and achieve low cost and flexible technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

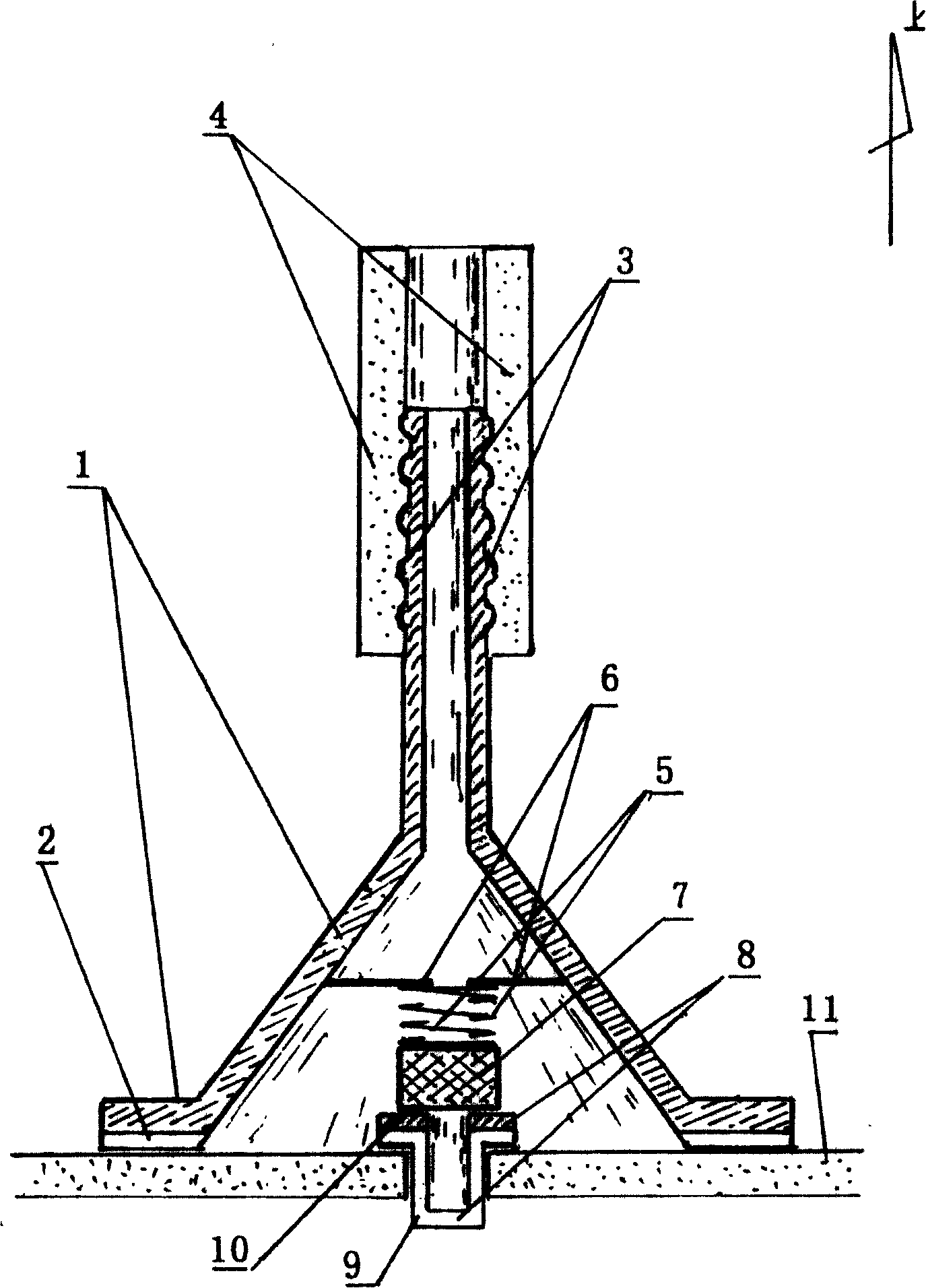

[0014] From figure 1 Shown in a sectional view of an example of the present invention: it is by horn-shaped sucker body wall 1, sucker inserts the sebific hose 4 that vacuumizes, plugs in small tube 3, the elastic quality sealing ring pad 2 that bonded on the bell mouth clip edge and the welding of built-in The vacuum suction cup formed by the spring fixing bracket 6 fixed on the body wall 1 of the horn suction cup and the small magnet 7 bonded on the head of the spring 5 and the specially designed inverted bowler hat shape, including metal and plastic 9, 10 two parts Inverted hat-shaped plug 8 and a smooth wall 11 with a vacuum orifice form a technical structure.

[0015] The use procedure of the present invention is: earlier drill the required vacuuming orifice at 11 appropriate positions. Then, choose a suitable plugging plug 8 to stick on the small magnet 7, and finally the horn suction cup body is aligned with the vacuum port with 8 and positioned on the vacuum port 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com