White spirit blending and stirring device

A stirring device, liquor technology, applied in biochemical cleaning device, enzymology/microbiology device, preparation of alcoholic beverages, etc., to achieve the effect of convenient operation, high stirring efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

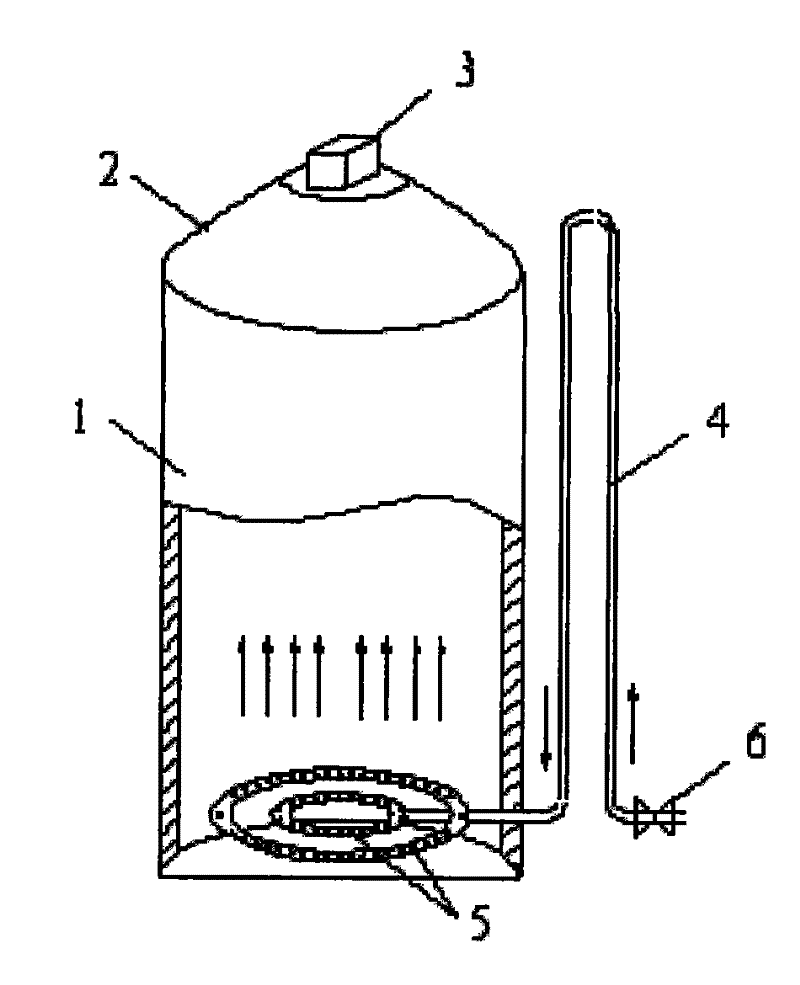

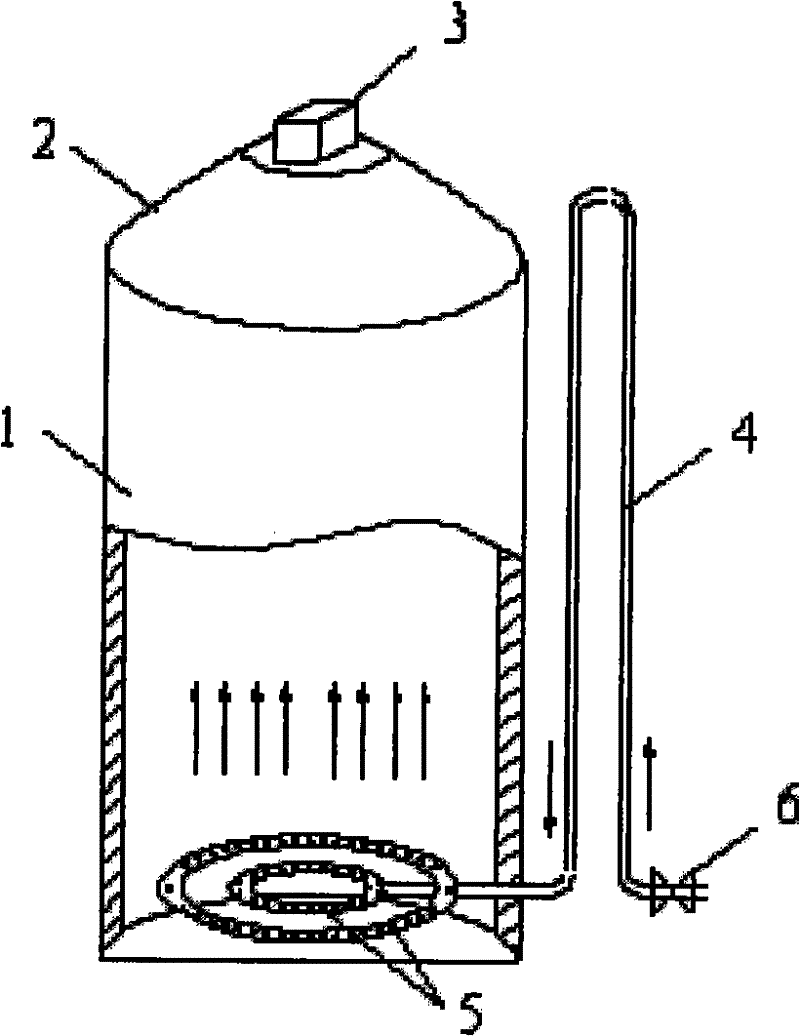

[0023] As shown in the figure, the top 2 of the tank body 1 of the blending tank is dome-shaped, and a breathing valve 3 is arranged in the center of the top 2 .

[0024] Set up the high pressure gas source. When clean high-pressure air is used as the gas stirring medium, the gas source is an air compressor, oil-water separator and air drying purifier connected in sequence; when other artificially prepared gases are used as the gas stirring medium, the gas source equipment should use high-pressure storage gas tank.

[0025] A gas pipeline 4 is drawn from the gas source and a gas control valve 6 is set to lead to the blending tank 1 . When one gas source supplies gas to multiple blending tanks, a main control valve is provided on the main gas pipeline, and sub-control valves 6 are respectively set on the branch gas pipelines outside each blending tank. Before the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com