Adjustable rear clamping device for car door sling

A rear clamping and door technology, which is applied in the direction of transportation, packaging, and load hanging components, can solve the problems of poor versatility of the door, and achieve the effects of meeting production needs, reducing repeated construction, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

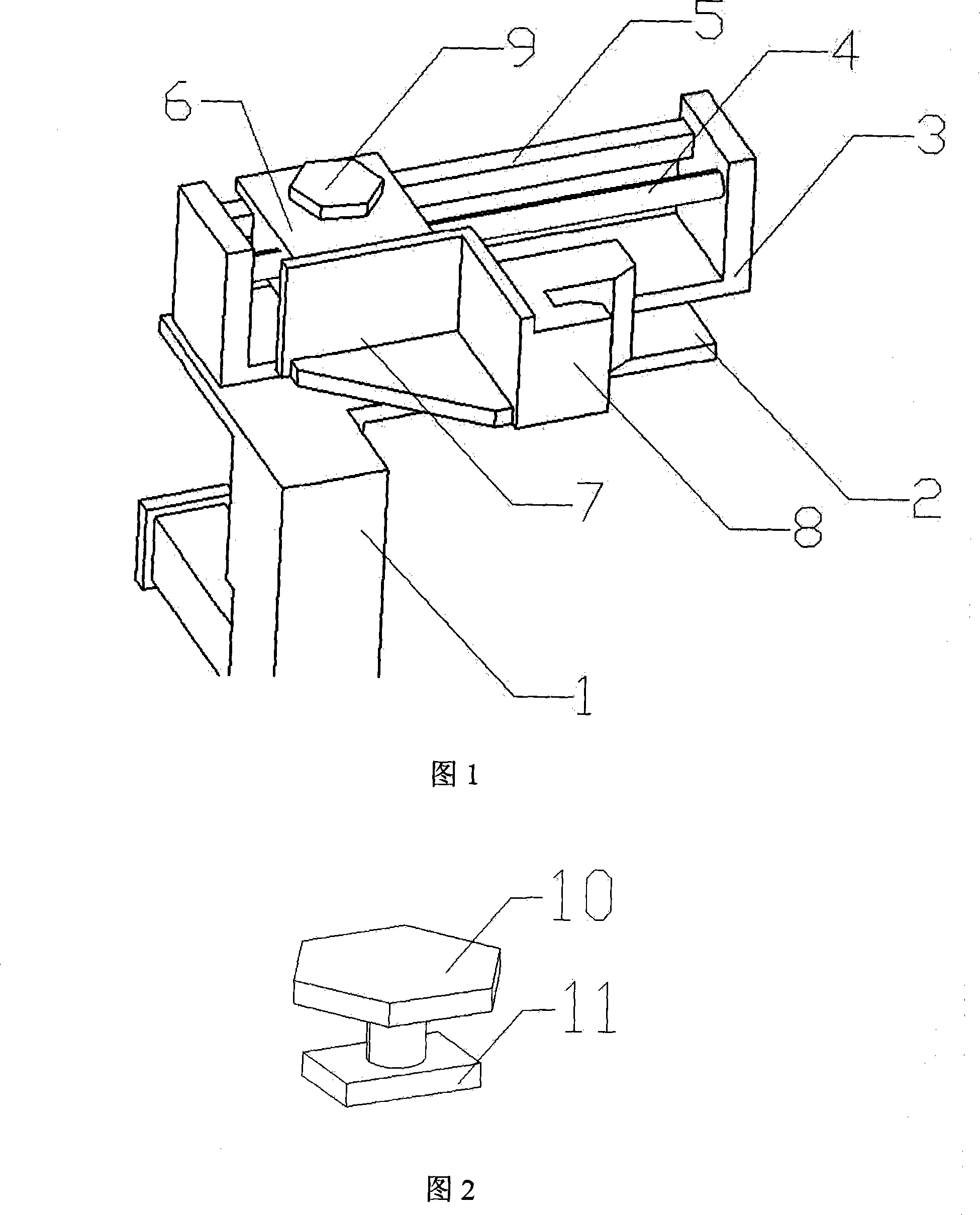

[0013] Referring to Fig. 1, this adjustable rear clamping device main part is an L-shaped theme support 1, and a steel flat plate 2 is welded on the upper end, and a track sliding mechanism is installed with bolts on the flat plate. The track sliding mechanism consists of a U-shaped bracket 3, a track bar 4 made of round steel, a locking bar 5 with teeth on the upper surface, and a slider 6 formed by a square steel block. The two steel bars are arranged in parallel, and the two ends Fixed on the U-shaped bracket 3. There is a circular through hole on the slide block 6, which is worn on the track bar 4, and the outer surface is close to the surface of the toothed locking bar 5, and the slide block 6 can move back and forth along the track bar 4 direction to adjust the clamping position. Slide block 6 sides are bolted with a triangular bracket 7, and the triangular bracket 7 front ends are bolted with a grooved clamp 8 of polyurethane, and the grooved clamp 8 is just correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com