Automatic assembling machine for transfusion regulator

An automatic assembly machine and regulator technology, applied in the field of machinery, can solve the problems of difficult assembly, low assembly efficiency, and low product quality, and achieve the effects of stable operation, improved assembly quality, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

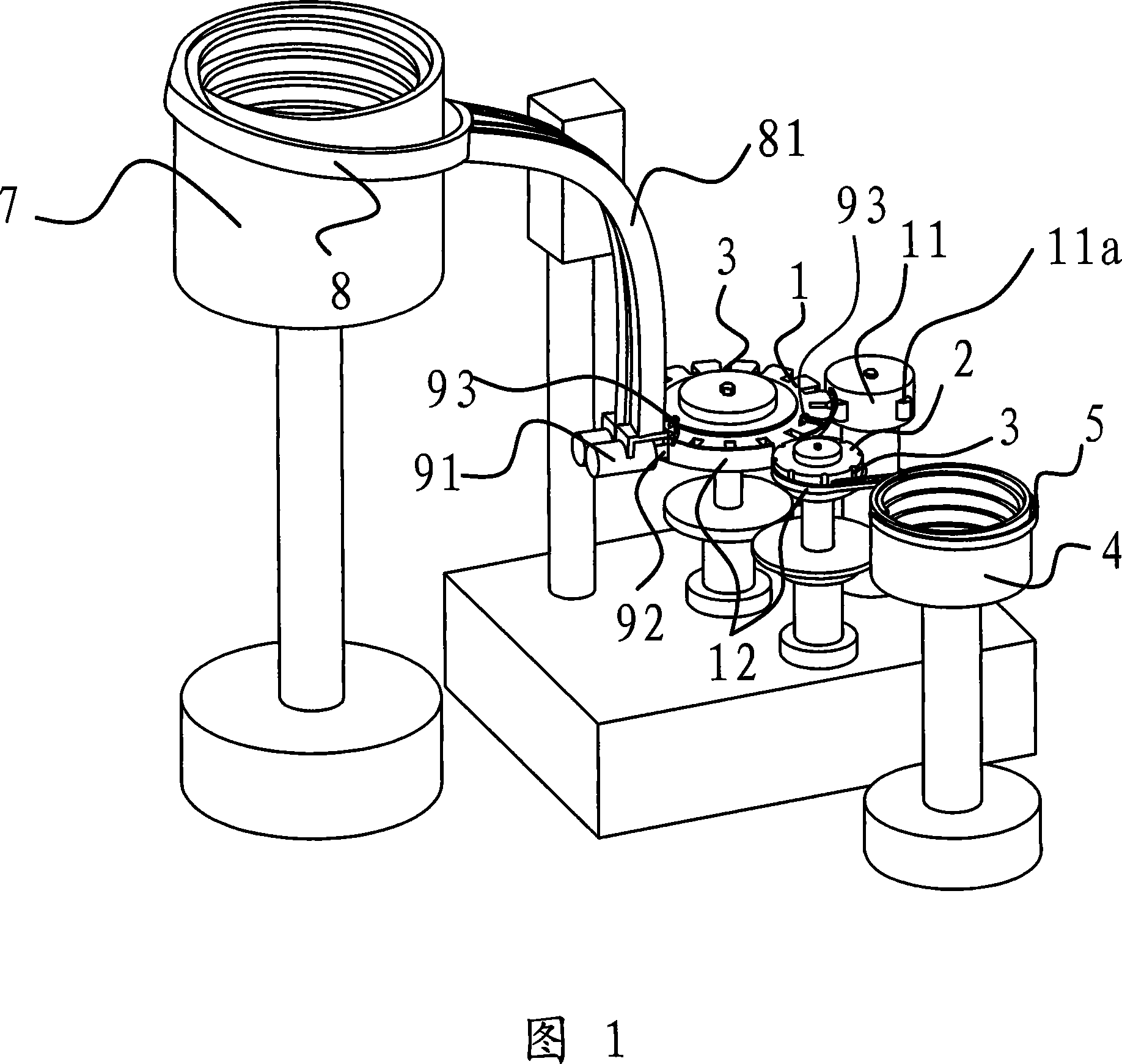

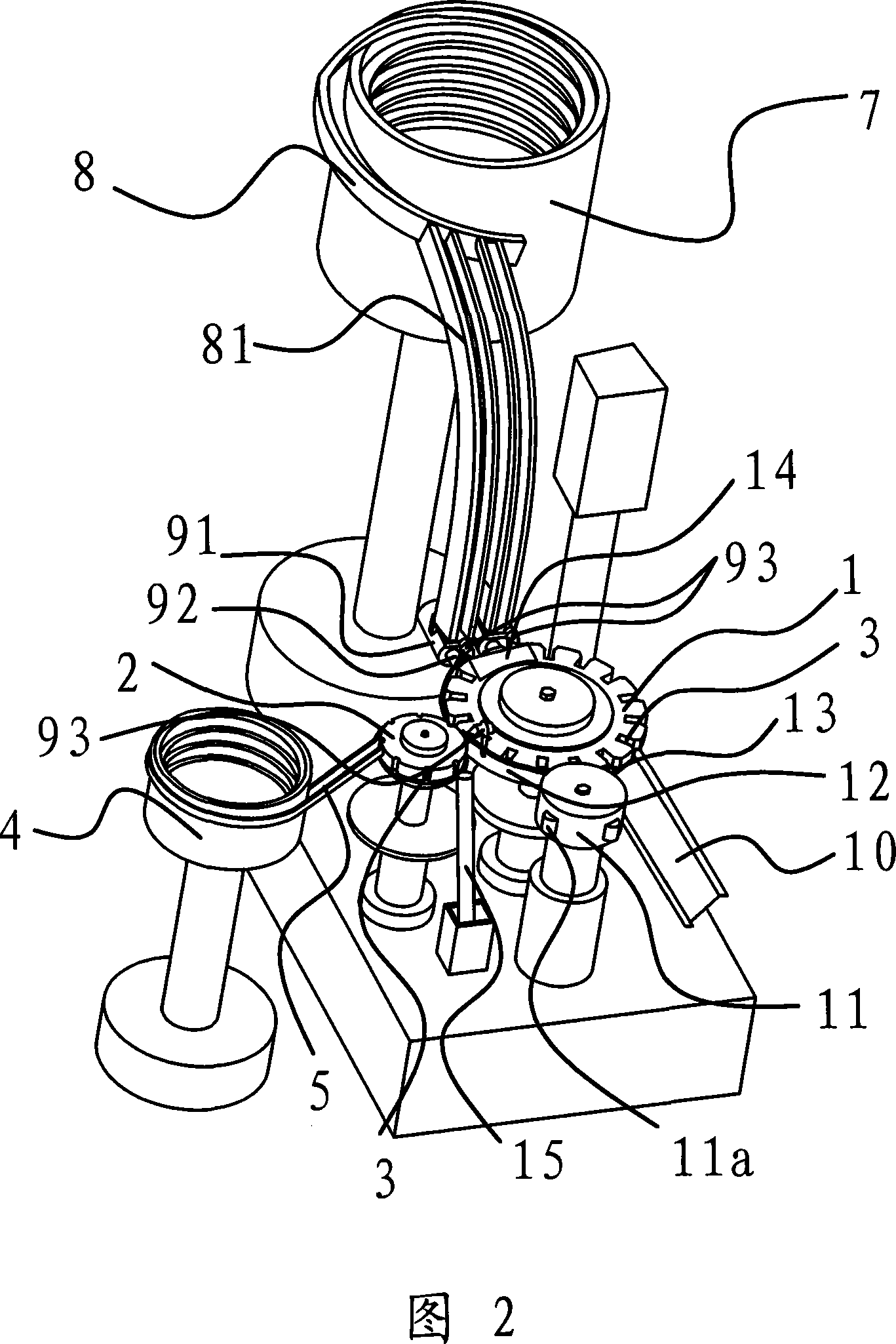

[0020] Embodiment 1: As shown in Figures 1 and 2, the automatic assembly machine for the infusion regulator is composed of a housing turntable 1, a roller turntable 2, a pressing roller 11, a housing feeding mechanism 9 and other components.

[0021] The edges of the housing turntable 1 and the roller turntable 2 are respectively provided with several evenly distributed notches 3, and the edges of the above two turntables are tangent. The roller feeder 4 is connected with a roller conveying guide rail 5 . The shell feeder 7 is connected with a shell conveying guide rail 8, and a shell feeding mechanism 9 is provided between the outlet of the shell conveying guide rail 8 and the shell turntable 1, and on the side of the shell turntable 1 A finished product discharge hopper 10 is provided. During work, the casing and the rollers are transported into the notches 3 of the casing turntable 1 and the roller turntable 2 respectively. Since the casing turntable 1 and the roller turn...

Embodiment 2

[0026]Embodiment 2: In this embodiment, two shell feeders 7 are provided on the side of the shell turntable 1, and each shell feeder 7 passes through a shell conveying guide rail with two conveying channels 81 8 is coupled with the housing turntable 1. The shell feeding mechanism 9 arranged between the discharge port of the shell conveying guide rail 8 and the shell turntable 1 includes a shell feeding cylinder 91, and the piston rod of each shell feeding cylinder 91 is fixedly connected with two The housing push rods 92 for pushing the housings into the corresponding notches 3 on the housing carousel 1 are provided one-to-one corresponding to the above-mentioned two conveying passages 81 . When a shell feeding cylinder 91 is working, it can control the work of two push rods 92 at the same time. The rest of this embodiment is similar to Embodiment 1, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com