Control rod for a pressurized-water nuclear reactor

A nuclear reactor and control rod technology, applied in the field of control rods, can solve problems such as unsatisfactory reduction of casing expansion, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

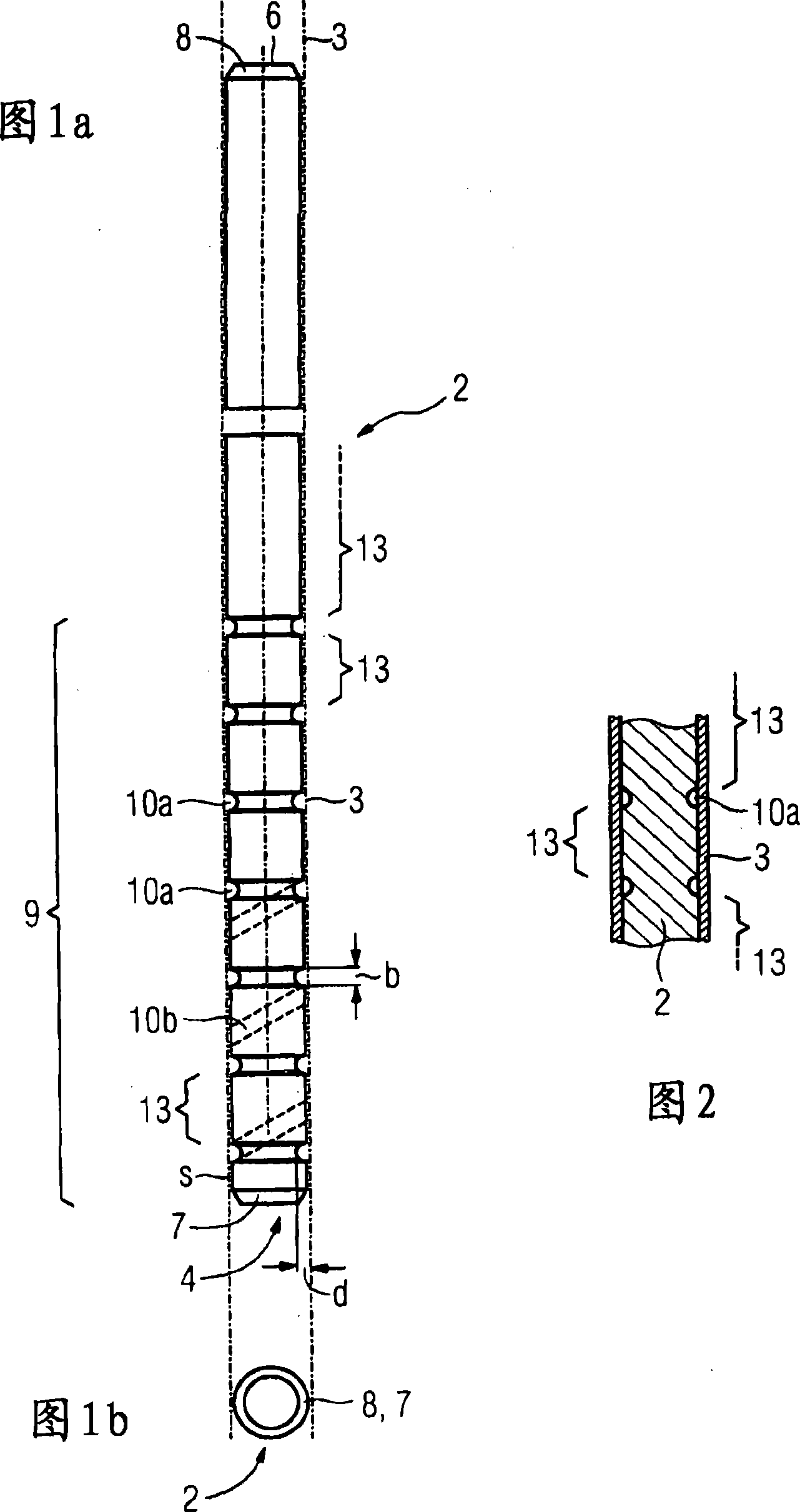

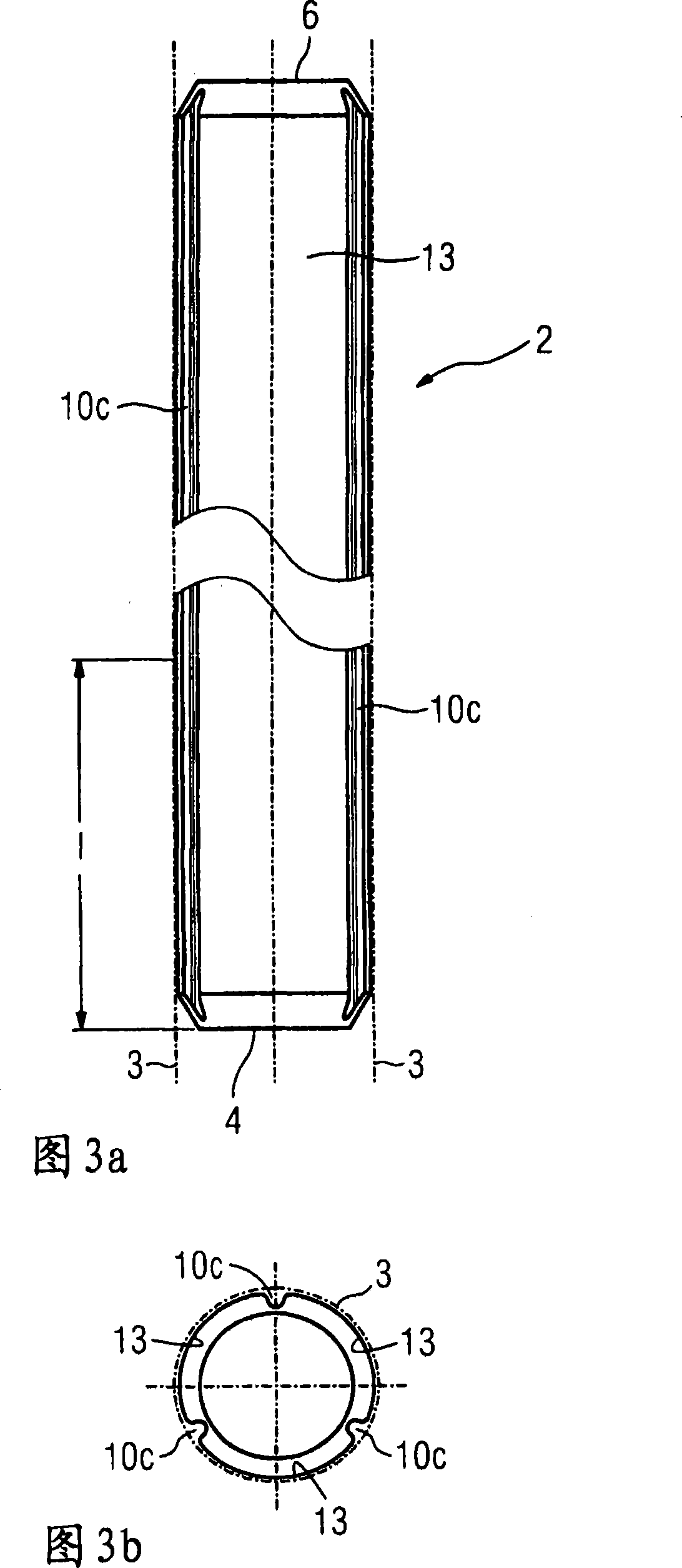

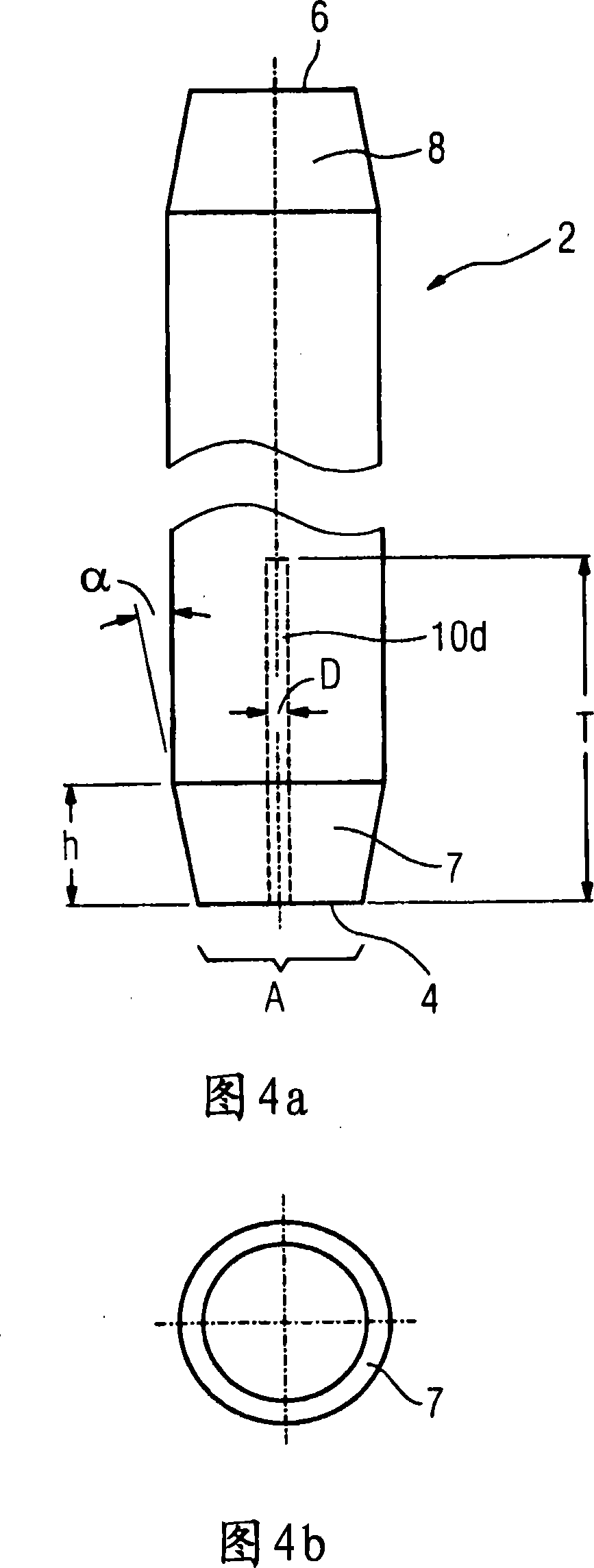

[0017] According to FIG. 1, an absorbent rod 2 has an essentially cylindrical shape. The absorption rod is conically shaped at its lower end 4 and upper end 6 , ie is provided with chamfers 7 or 8 . The absorption rod 2, which can be composed of a plurality of sub-rods in the axial direction, is accommodated in a sleeve 3, which is only indicated by dotted lines in the drawing, and which surrounds the absorption rod in a gas-tight manner. A “lower end” is to be understood here as the lower end of the absorber rod 2 through which the absorber rod is guided together with the sleeve 3 into the control rod guide tube of the fuel element in the installed state and during operation.

[0018] In the lower section 9 , which adjoins this conical region 7 , the absorber rod 2 is provided with a plurality of recesses in the form of annular grooves 10 a or grooves. In the region of these recesses, the absorber rod 2 thus has a cross-sectional area perpendicular to its longitudinal axis w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com