Triangle mechanism of computer plain flat knitter

A technology of flat knitting machine and needle guard triangle, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of strict processing precision of needle jack 17, increase of manufacturing cost, and increase of overall machine volume, etc., and achieves The volume of the whole machine is reasonably reduced, the width of the machine head is reduced, and the effect of needle movement is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

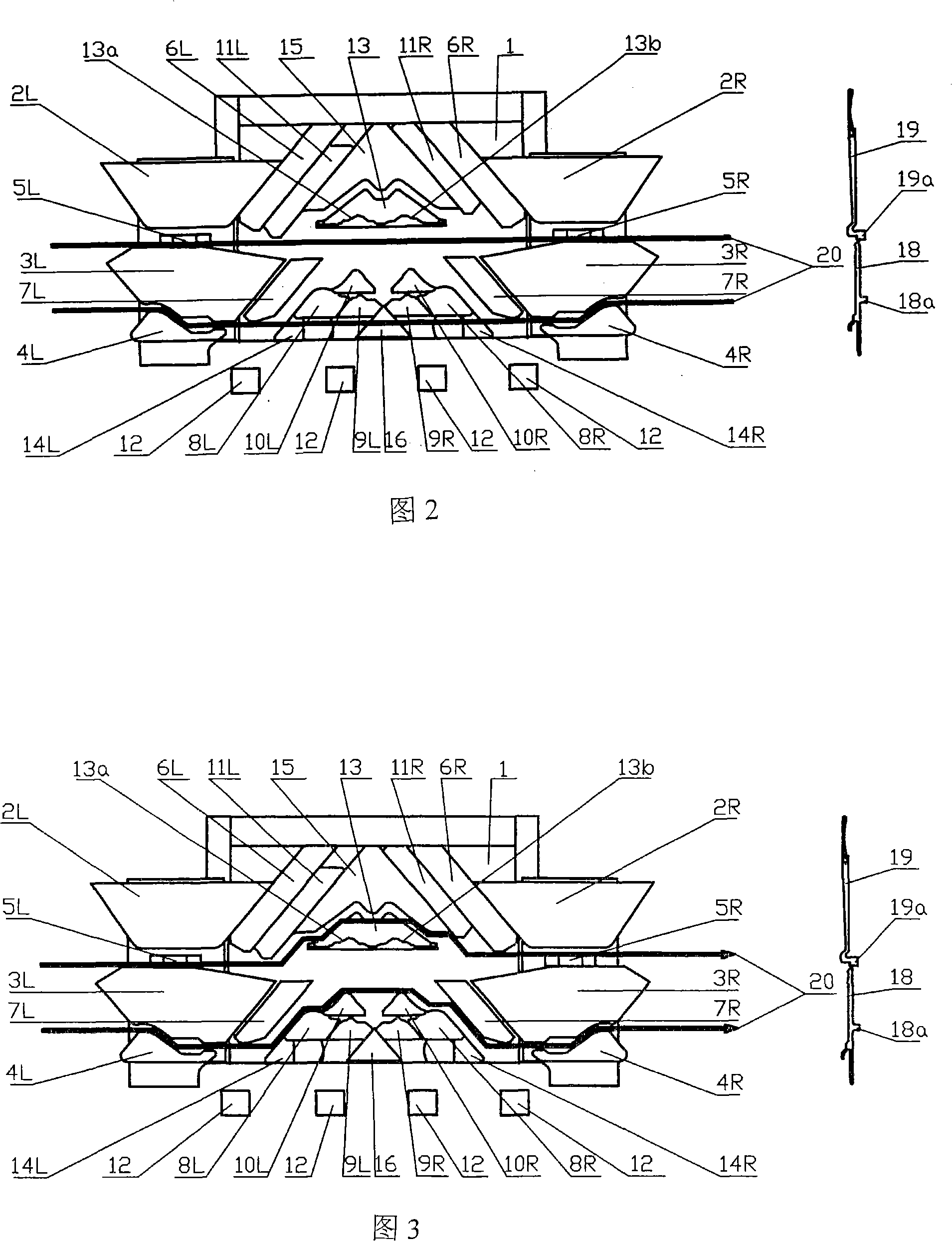

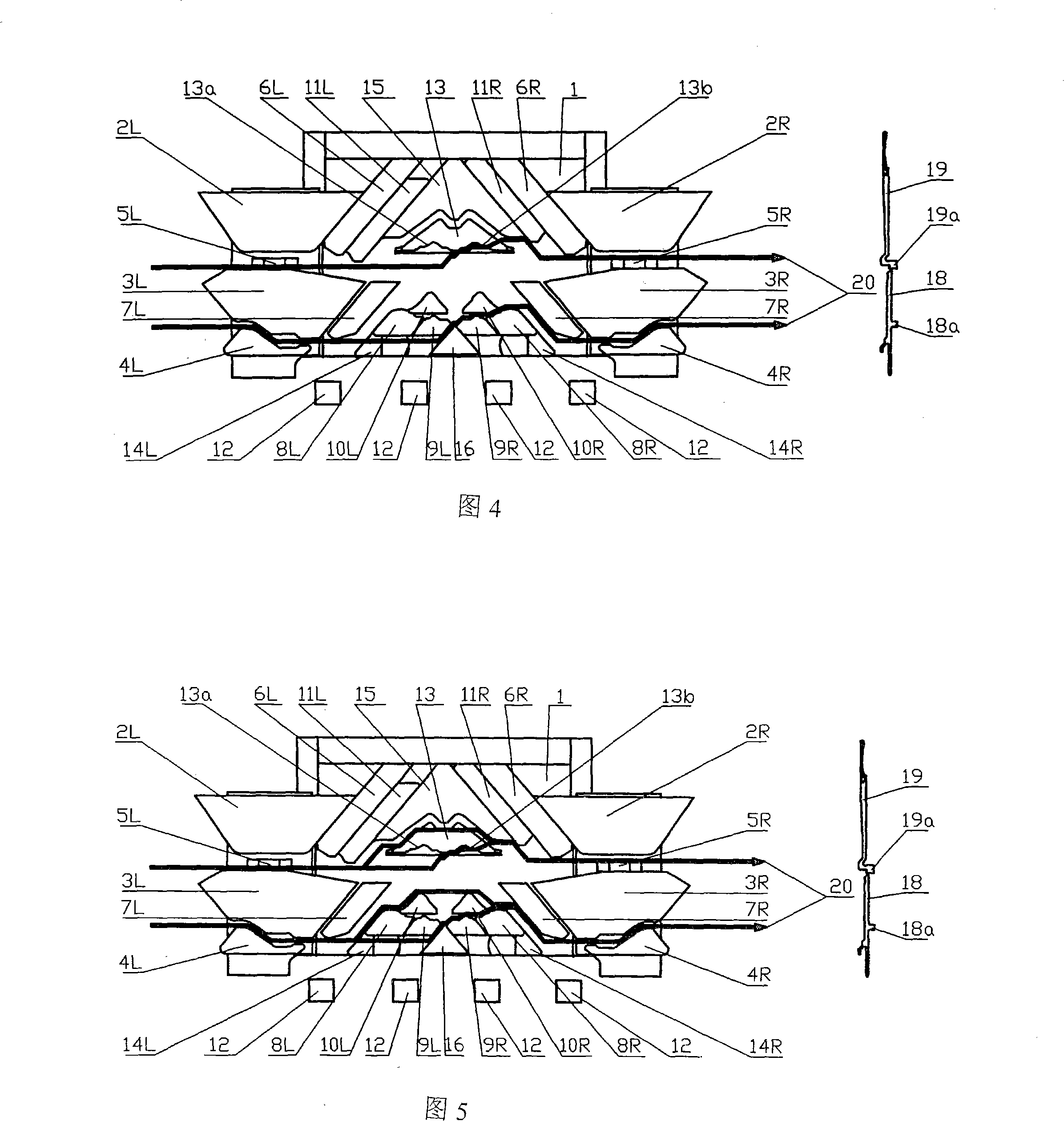

[0030] In order to enable the examiners of the patent office, especially the public, to further understand the technical essence and beneficial effects of the present invention, the specific implementation methods of the present invention are described in detail below in conjunction with the accompanying drawings and examples. However, the applicant declares that any formal changes or textual modifications based on the concept of the present invention shall be regarded as the scope of the technical solutions of the present invention.

[0031] Please see Fig. 1, a triangular bottom plate 1 is provided, which is installed on the machine head of the knitting mechanism of the computerized flat knitting machine. The machine head has front and rear points, so the triangular bottom plate 1 has a pair of The industry is called the front and rear triangular bottom plates. The following statements are only for a triangular base plate 1, the knitting needles of the knitting needle assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com