Vibration damping unit

A technology of sealing device and connecting device, applied in the direction of spring/shock absorber, vibration suppression adjustment, rotation vibration suppression, etc., can solve problems such as high price success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

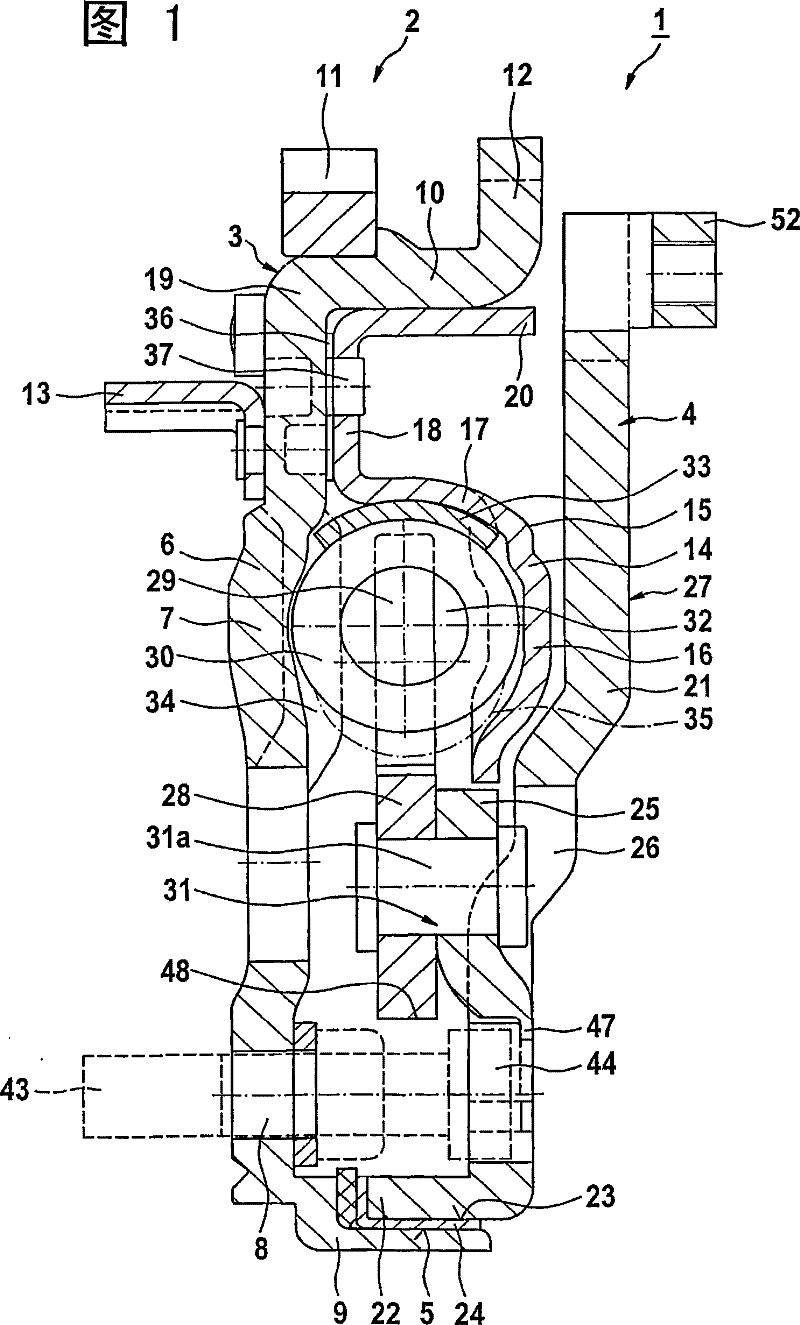

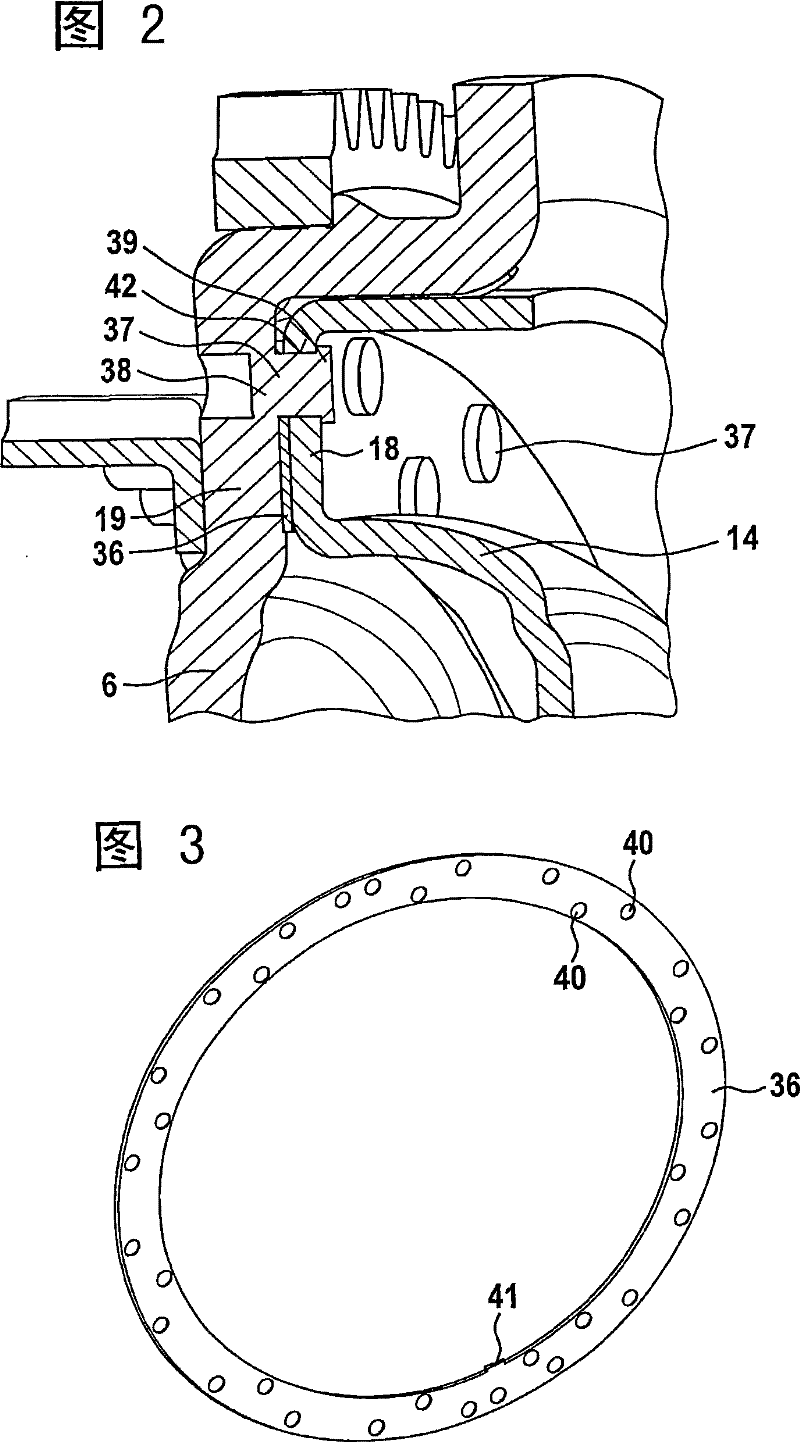

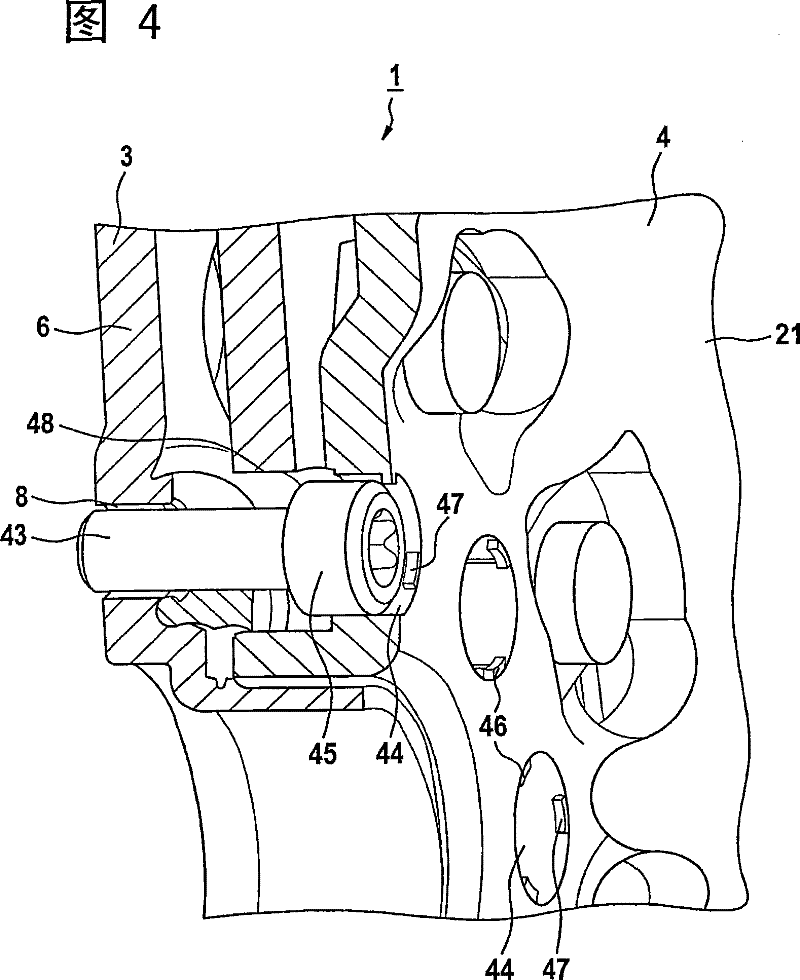

[0033] figure 1 The torsional vibration damping device 1 shown in the figure forms a so-called dual-mass flywheel 2, which comprises a primary mass 3 and a secondary mass 4, which are centered and rotatably mounted relative to each other via a bearing device 5 . In the exemplary embodiment shown, the bearing device 5 is formed by a so-called slide bearing. Reference is made to DE 198 34 728 A1 with regard to the function and possible configuration of such plain bearings, so that a detailed discussion of this is not necessary within the scope of the present application.

[0034] The primary mass 3 and the secondary mass 4 are formed by formed sheet metal parts, which are preferably configured as punched and / or pressed parts. Parts produced in this way can be produced practically without tools, whereby subsequent cutting operations can be dispensed with. If necessary, only the necessary screw threads have to be machined afterwards. However, this subsequent work process can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com