Four-link lever folding bicycle frame

A four-link and frame technology, which is applied in the frame field of two-wheeled vehicles, can solve the problems of affecting the bearing capacity, affecting the strength of the horizontal tube, and complexity, and achieves improved stress conditions, improved safety, and simple folding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

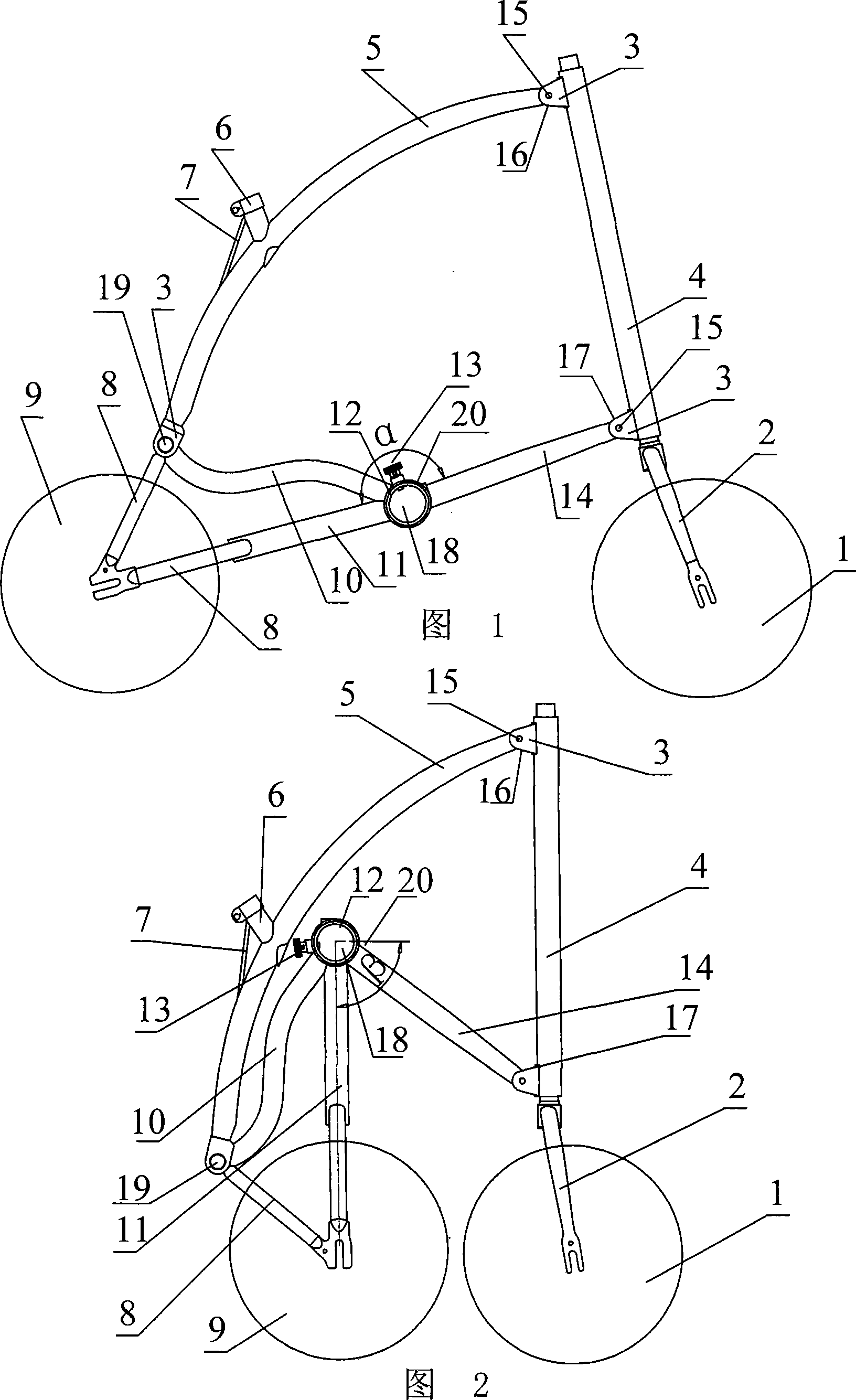

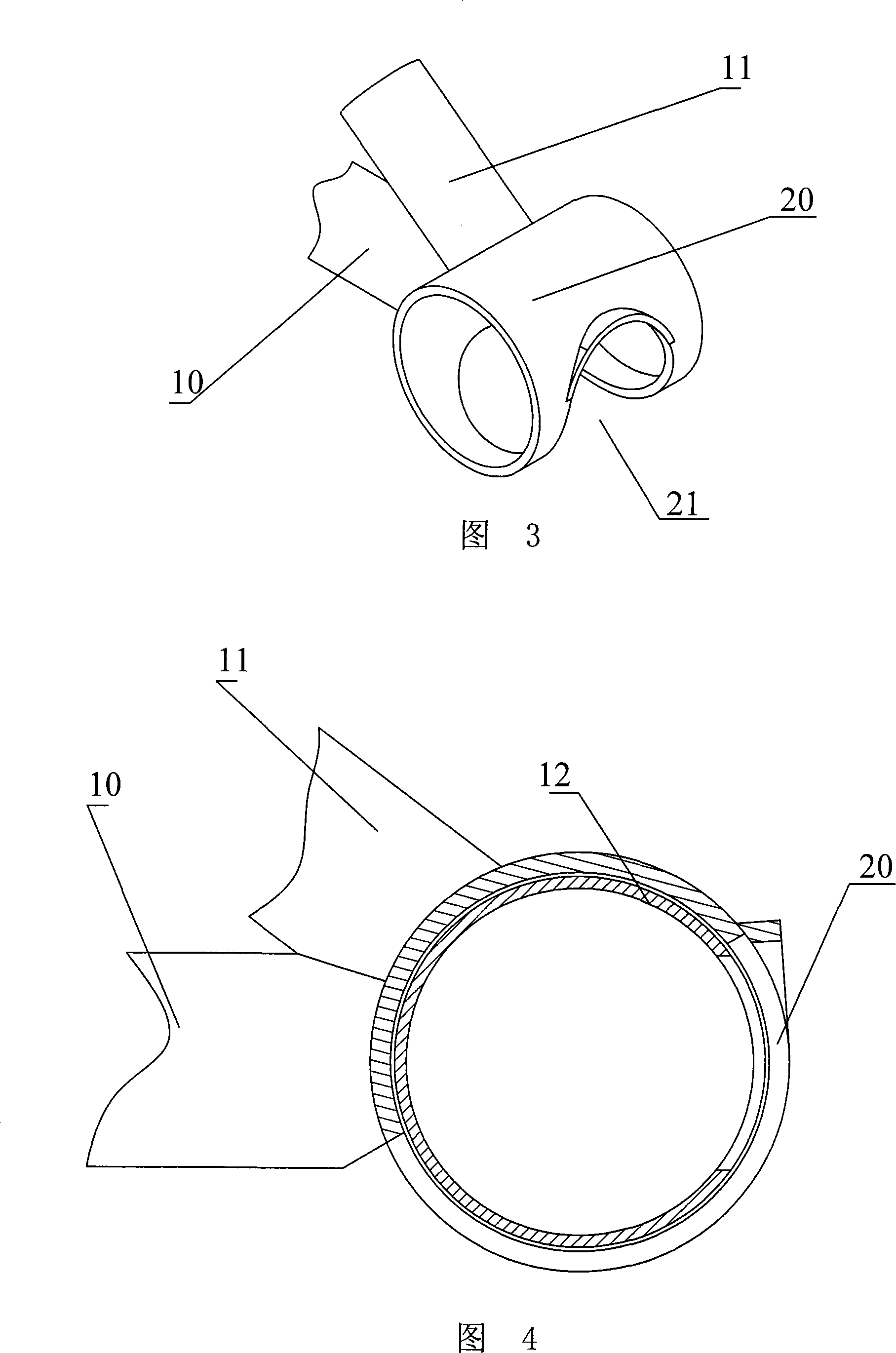

[0016] As shown in the figure: the upper and lower ends of the head tube 4 are respectively hinged on the upper tube 5 and the front section 14 of the down tube, and the folding joint 16 and the folding joint 17 are respectively formed at the hinge points; The lower end is hinged, the rear end of the front section 14 of the lower tube is connected with the inner bottom bracket 12, the front end of the rear section 11 of the lower tube is connected with the outer bottom bracket 20, and the outer bottom bracket 20 is set outside the inner bottom bracket 12 to form a folding joint 18 ; The rear end of the lower tube rear section 11 is connected with the rear fork 8, and the rear end of the upper tube 5 is hinged with the rear fork to form a folding joint 19. A seat tube 6 is provided on the top tube 5 .

[0017] When folding, use the reinforcing tube 10 as a handle to force the front section 14 of the lower tube and the rear section 11 of the lower tube to take the folding joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com