Material receiving device of cold drawing machine

A technology of material receiving device and cold drawing machine, which is applied in the field of hydraulic cold drawing machine equipment and material receiving device of cold drawing machine, and can solve the problems of high labor intensity, labor and time, and the lack of automatic material receiving device of cold drawing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

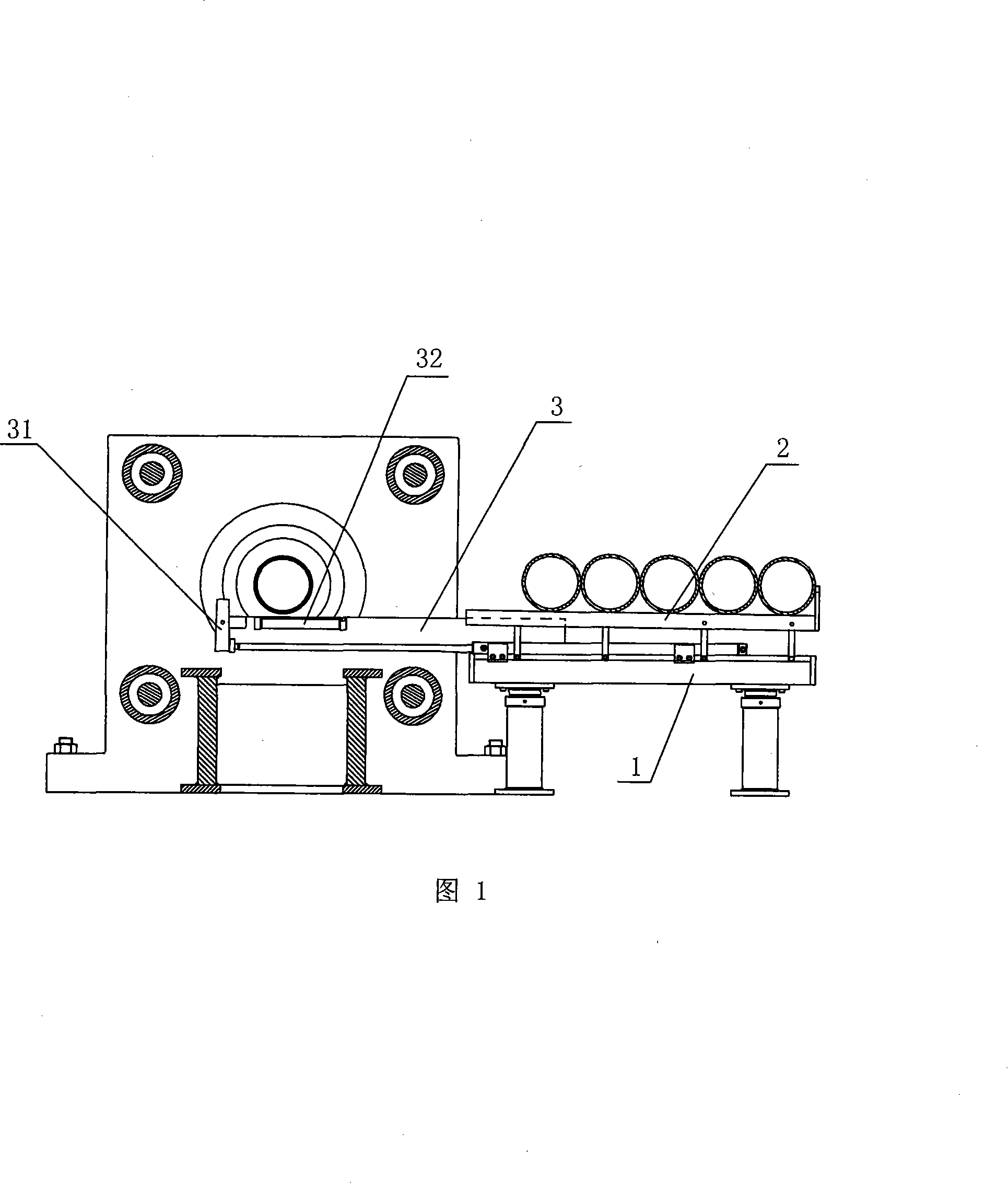

[0012] As shown in Figure 1, a material receiving device for a cold drawing machine has a pallet 1, a material carrier 2 is arranged on the pallet 1, and a telescopic material receiving frame is arranged between the pallet 1 and the material carrier 2 3. A pusher baffle 31 is provided at the protruding end of the receiving rack 3 .

[0013] The material receiving frame 3 is driven by a hydraulic cylinder arranged on the pallet 1 to move telescopically, and the pallet 1 is provided with a slide rail for the material receiving frame 3 to stretch in and out.

[0014] The receiving frame 3 is provided with a roller group 32 on a section close to its pushing baffle 31 .

[0015] The material loading surface of the material receiving rack 2 has a certain inclination, and the inclination angle faces away from the material receiving end of the material receiving rack 2 .

[0016] The material receiving device of the present invention is arranged at the discharge port of the cold draw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap