A silicon slice deviation dynamic regulation method and device by photoelectric switch

A photoelectric switch, silicon wafer technology, applied in circuits, electrical components, transportation and packaging, etc., can solve problems such as affecting the silicon wafer process, complex operating procedures, and inability to guarantee silicon wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

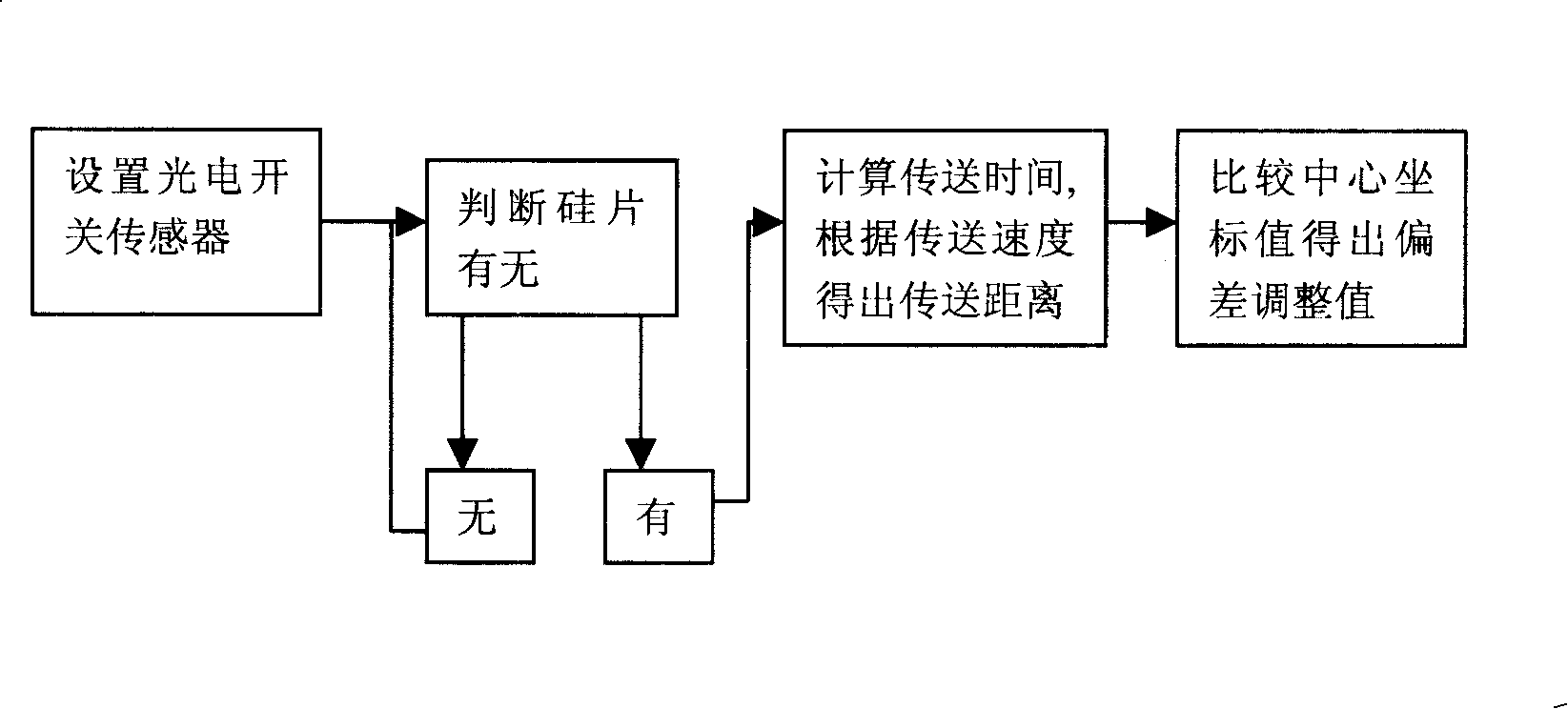

[0020] Basic detection principle: such as figure 1 As shown, in the process of the manipulator transporting the silicon wafer from the transfer chamber to the reaction chamber, the transfer time of the silicon wafer is judged by the photoelectric switch sensor 1, and the running distance is calculated by combining the average speed of the manipulator to obtain the current silicon wafer on the manipulator. The center coordinate of the chip is compared with the center coordinate value of the silicon chip when there is no deviation, and the difference obtained is the required deviation adjustment value.

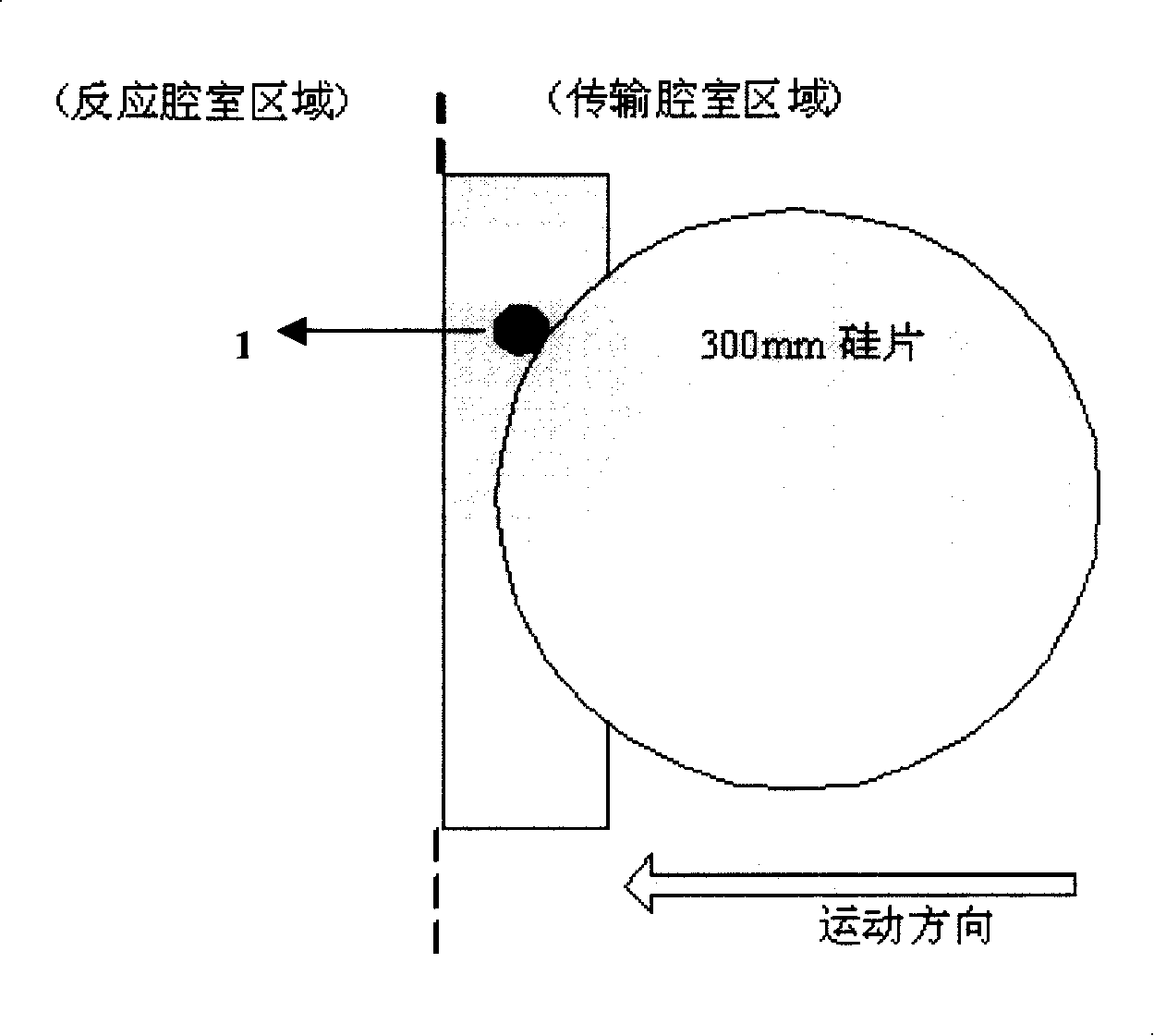

[0021] Device layout: as figure 2 , Figure 4 As shown, the photoelectric switch sensor 1 is located off-center at the connection between the transfer chamber and the reaction chamber, and the manipulator is used to transport the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com