Comprehensive test platform

A technology of comprehensive test bench and test bench, which is applied in the field of comprehensive test bench, can solve the problems of low work efficiency, waste of lubricating oil, messy assembly workshop, etc., and achieve the effects of convenient adjustment, accurate testing and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

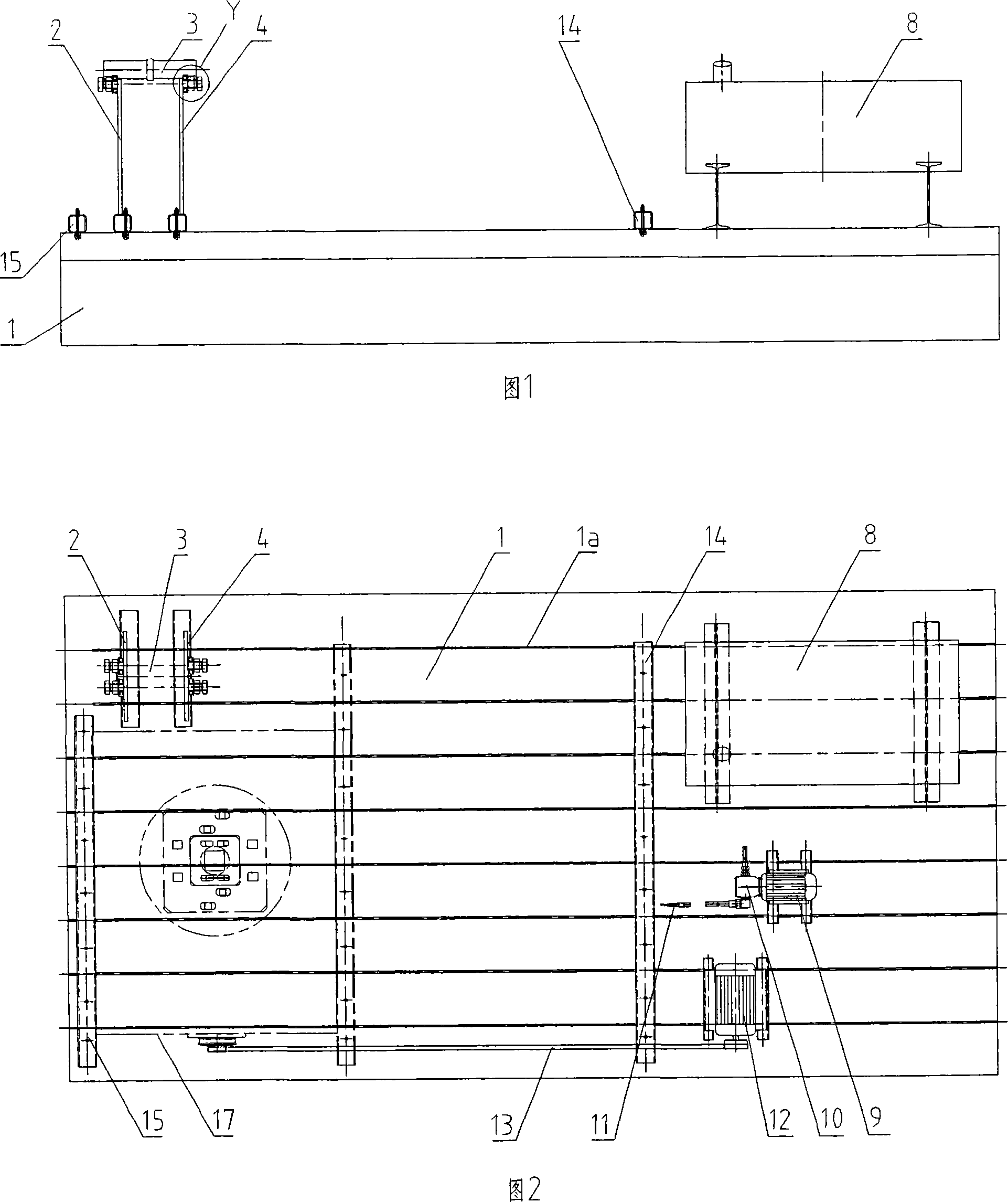

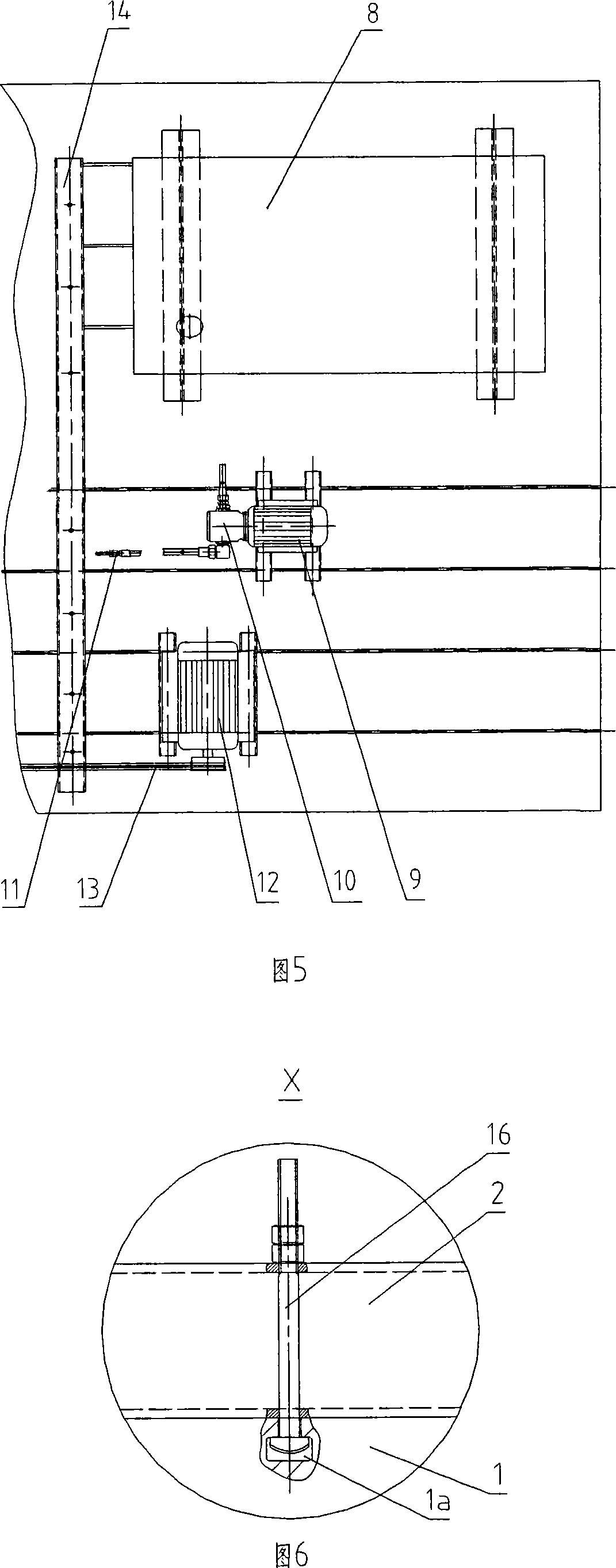

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the comprehensive test bench of the present invention includes a platform 1, a static balance test device, a run-in test device, and a refueling and oil pumping device on which the upper plane is a reference plane, and the upper plane of the platform 1 is provided with certain intervals Transverse T-slot 1a.

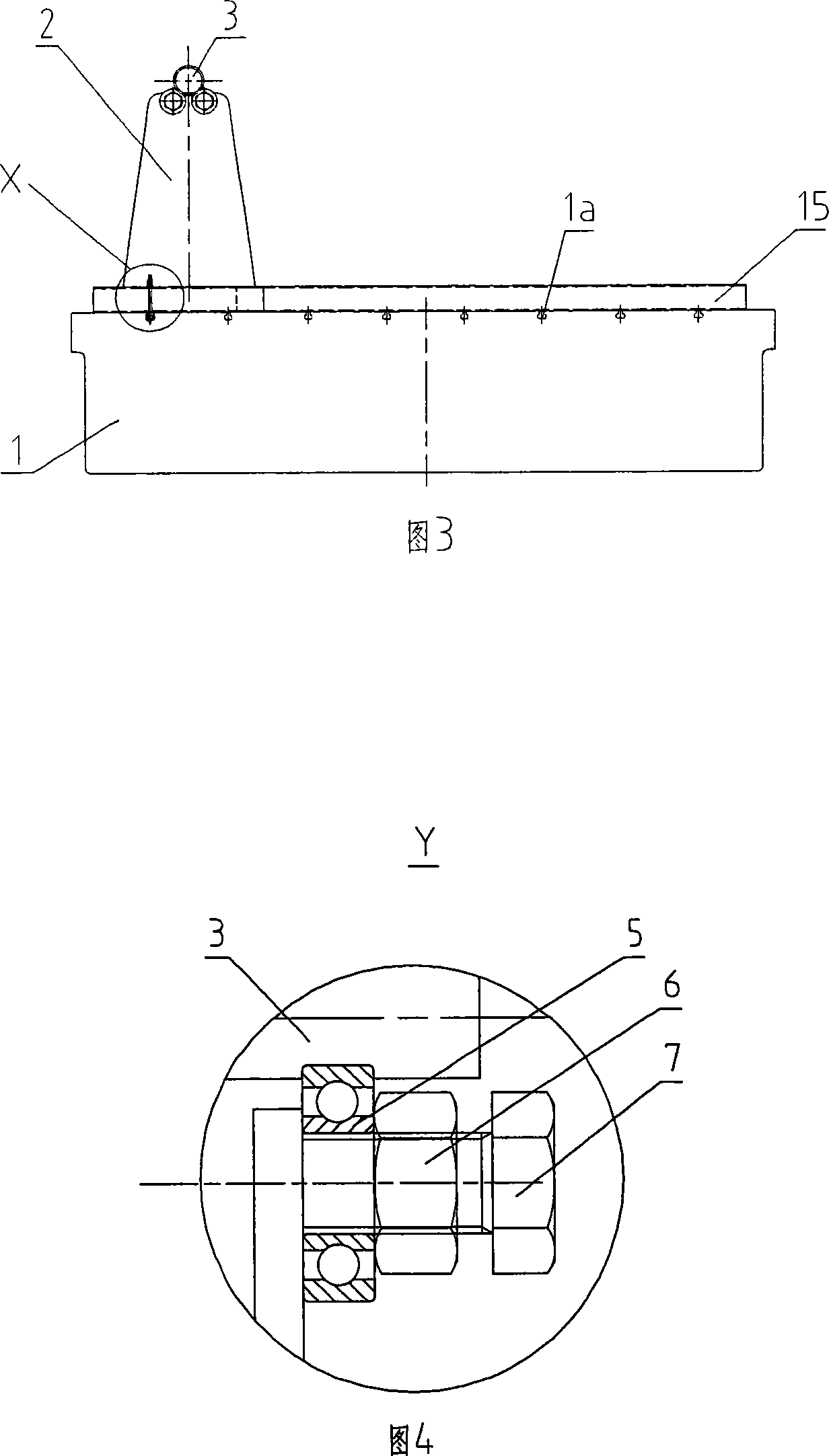

[0017] As shown in Figure 1, Figure 2, Figure 3, Figure 4, and Figure 6, the static balance test device consists of a mandrel support 2, a mandrel 3, a mandrel support 4 and a pair of bearings 5 connected to each mandrel support , the mandrel support 2 and the mandrel support 4 are fixed on the platform 1 through the T-bolt 16 and the T-slot 1a of the platform 1, between a pair of bearings 5 of the mandrel support 2 and a pair of bearings 5 of the mandrel support 4 The bearings 5 are connected to the mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com