Construction method for passenger transport dedicated line bolster embedded large-size ballastless track

A long sleeper buried type, passenger dedicated line technology, applied in the field of passenger dedicated line long sleeper buried large ballastless turnout construction, can solve the problems of difficult rail row transportation, long rail parts, high assembly precision, etc., to achieve construction measurement and The effect of high control precision, good quality and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

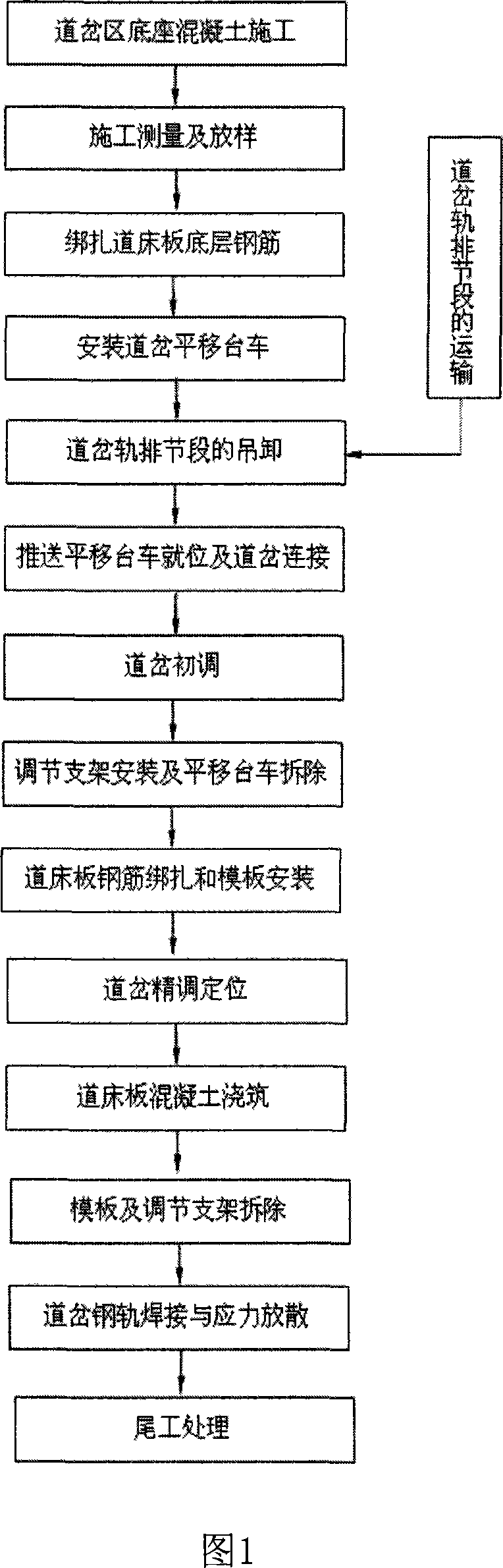

[0054] A specific construction process of a long sleeper buried type large ballastless turnout method for passenger dedicated lines per hour, as shown in Figure 1, including the following steps:

[0055] (1) Concrete construction of the base of the turnout area

[0056] The base of the turnout area is a C30 reinforced concrete structure, which is arranged in a trapezoidal shape according to the line shape of the turnout. The concrete is constructed by factory-mixed concrete and continuous pouring. Rough base concrete surface.

[0057] (2), construction measurement and stakeout

[0058] Use high-precision total station and electronic level to re-measure the CPIII reference network in the range of 300m before and after the turnout, stake out the turnout foundation piles at the turnout center, fork tail, fork head, starting and ending points of the curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com