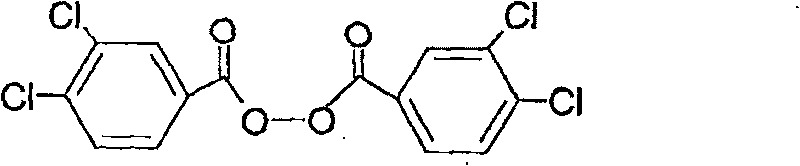

Method for preparing 3,4-dichlorobenzoperoxide

A technology of dichlorobenzoyl peroxide and dichlorobenzoyl chloride, which is applied in 3 fields, can solve problems such as low decomposition temperature and increased unsafe factors, achieve high decomposition temperature, use equipment and process requirements that are not harsh, and have high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

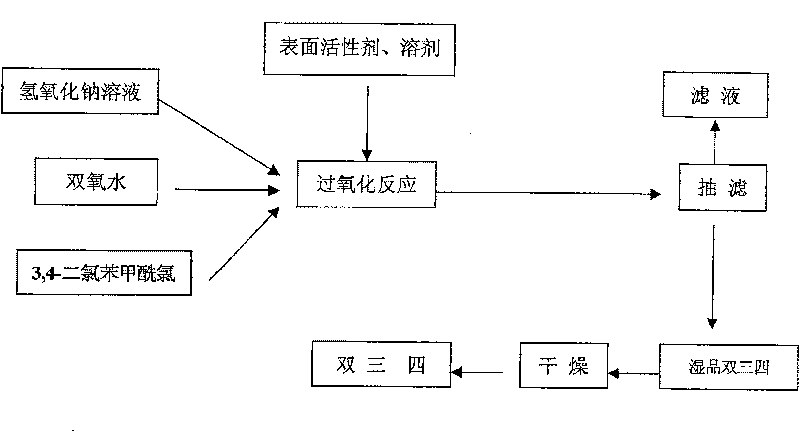

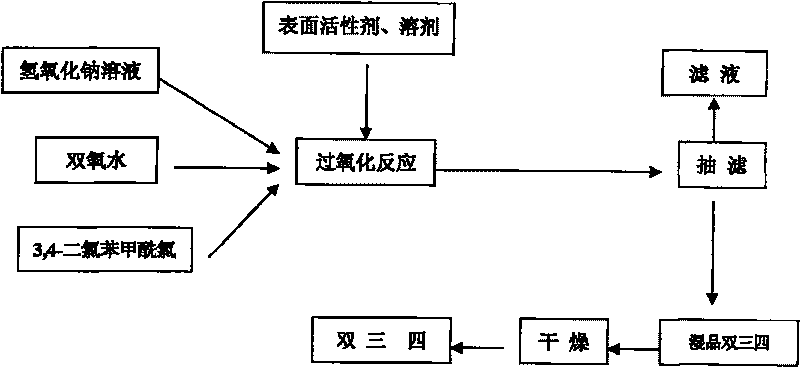

Method used

Image

Examples

Embodiment 1

[0015] Put 8.362mol of sodium hydroxide solution, 5.537mol of hydrogen peroxide, 3000g of water, 96g of sodium dodecylsulfonate, and 960g of toluene into the reaction kettle, stir, adjust the temperature to 0°C, and dropwise add industrial grade 3,4-dichlorobenzene Formyl chloride 5.65mol (1200g), the dropping temperature is maintained at 0-5°C, the dropping time is 15min, and after the dropwise addition is completed, the reaction is kept at 35°C for 200min to obtain the reactant, which is filtered and washed to obtain 3,4- The wet product of benzoyl dichloroperoxide (wet product), the wet product was dried in a desiccator at 35°C for 5h to obtain 1989.6g of a light yellow solid, with a yield of 92.7%, and a liquid chromatography area normalized purity of 98.6%, decomposed The temperature is 131.6°C.

Embodiment 2

[0017] Put 9.605mol of sodium hydroxide solution, 7.062mol of hydrogen peroxide, 3600g of water, 180g of sodium dodecylbenzenesulfonate, and 1440g of hexane into the reaction kettle, stir, adjust the temperature to 12°C, and dropwise add industrial grade 3,4-di Chlorobenzoyl chloride 5.65mol (1200g), the dropping temperature is maintained at 10-15°C, the dropping time is 55min, and after the dropwise addition is completed, the reaction is kept at 15°C for 110min to obtain the reactant, which is filtered and washed to obtain 3,4 -Dichlorobenzoyl peroxide wet product, dry the wet product in a desiccator at 40°C for 5h, obtain 2024.5g of light yellow solid, yield 94.3%, liquid chromatography area normalized purity 98.9%, decomposition temperature 131.9°C .

Embodiment 3

[0019] Put 10.735mol of sodium hydroxide solution, 6.215mol of hydrogen peroxide, 5040g of water, 204g of sodium lauryl sulfate, and 3000g of dichloroethane into the reaction kettle, stir, adjust the temperature to 20°C, and dropwise add industrial grade 3,4-dichloroethane Chlorobenzoyl chloride 5.65mol (1200g), the dropping temperature was maintained at 20-24°C, the dropping time was 92min, and after the dropwise addition was completed, the reaction was kept at 28°C for 42min to obtain the reactant, which was filtered and washed to obtain 3,4 - Dichlorobenzoyl peroxide wet product, dry the wet product in a desiccator below 38°C for 5 hours to obtain 2011.0 g of light yellow solid, yield 93.6%, liquid chromatography area normalized purity 99.1%, decomposition temperature 131.9 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com