Pallet

A tray and chassis technology, which is applied in the field of trays that are convenient for lens module assembly and transportation, can solve the problems of time-consuming, unfavorable lens module production efficiency, and many manpower, so as to achieve convenient and fast use, easy transportation and transfer, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The tray provided by the embodiment of the technical solution will be further described below in conjunction with the accompanying drawings.

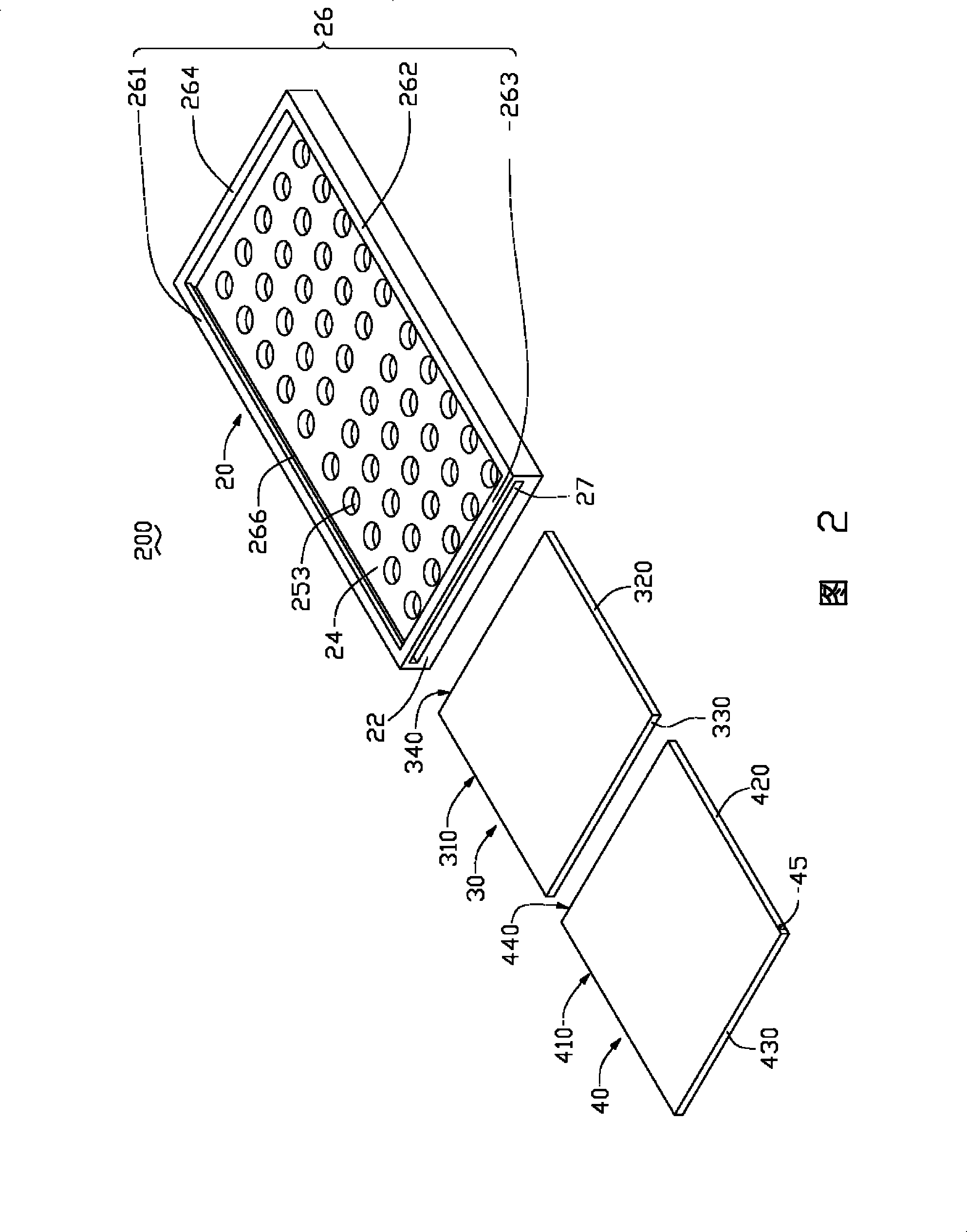

[0015] Referring to FIG. 2 and FIG. 3 , Embodiment 1 of the technical solution provides a tray 200 , which includes a chassis 20 , a first sliding cover 30 and a second sliding cover 40 .

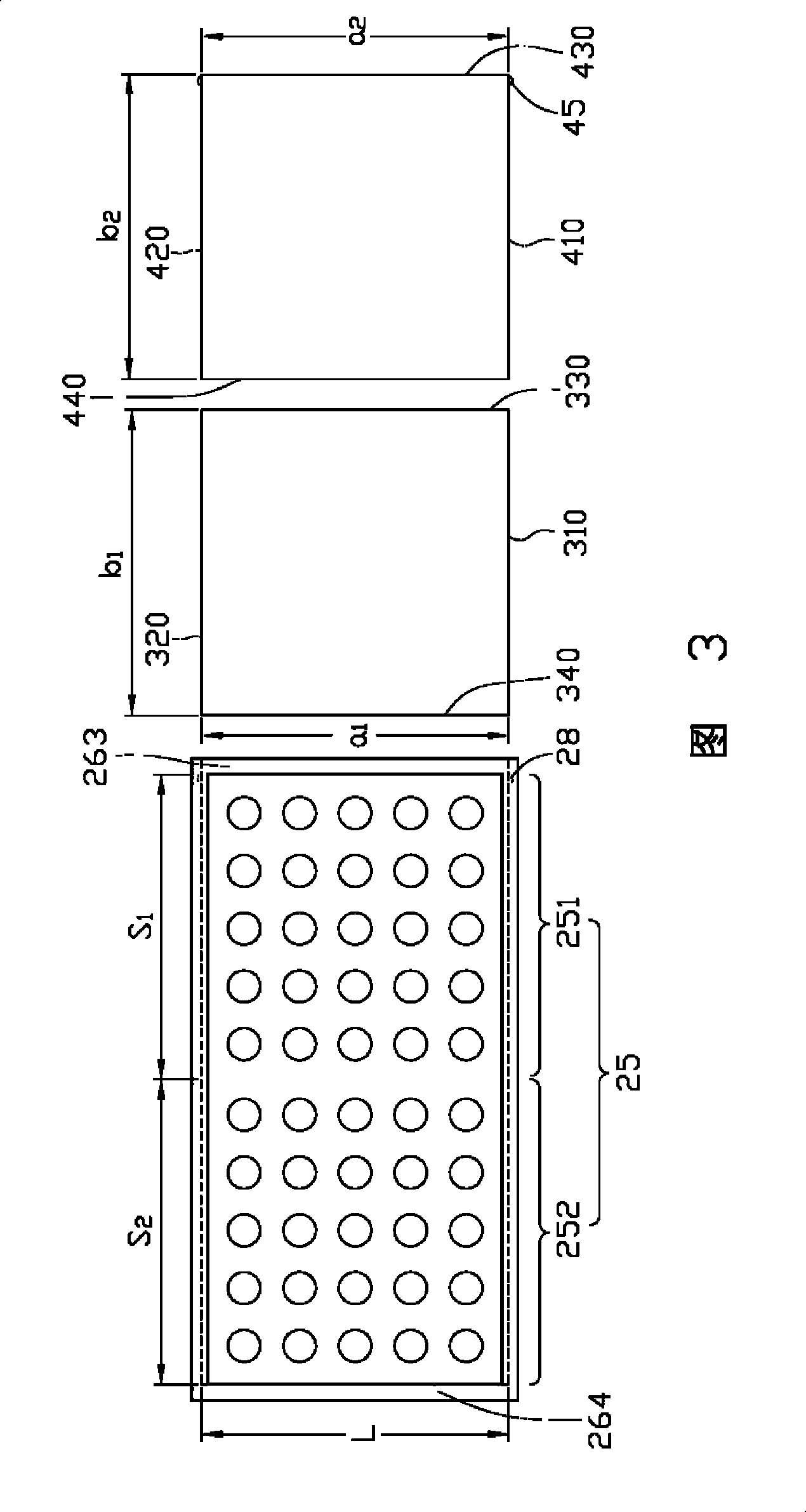

[0016] The chassis 20 includes a chassis body 22 . The chassis body 22 is rectangular and has a bearing surface 24 . The carrying surface 24 includes a central carrying area 25 and a peripheral area (not shown) surrounding the carrying area 25 .

[0017] The carrying area 25 includes a first carrying area 251 and a second carrying area 252 adjacent to the first carrying area 251 . The first carrying area 251 and the second carrying area 252 have the same size, and the length of the first carrying area 251 (S 1 ) is equal to the length of the second bearing region 252 (S 2 ). The first loading area 251 and the second loading area 252 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com