0.4mmquick-speed jigs for needle tube under 0.4mm and method of use thereof

A fixture and fast technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of inconvenient detection of detection instruments, affecting the accuracy of detection, high labor intensity, etc., and achieve low cost, easy manufacture, and convenience Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

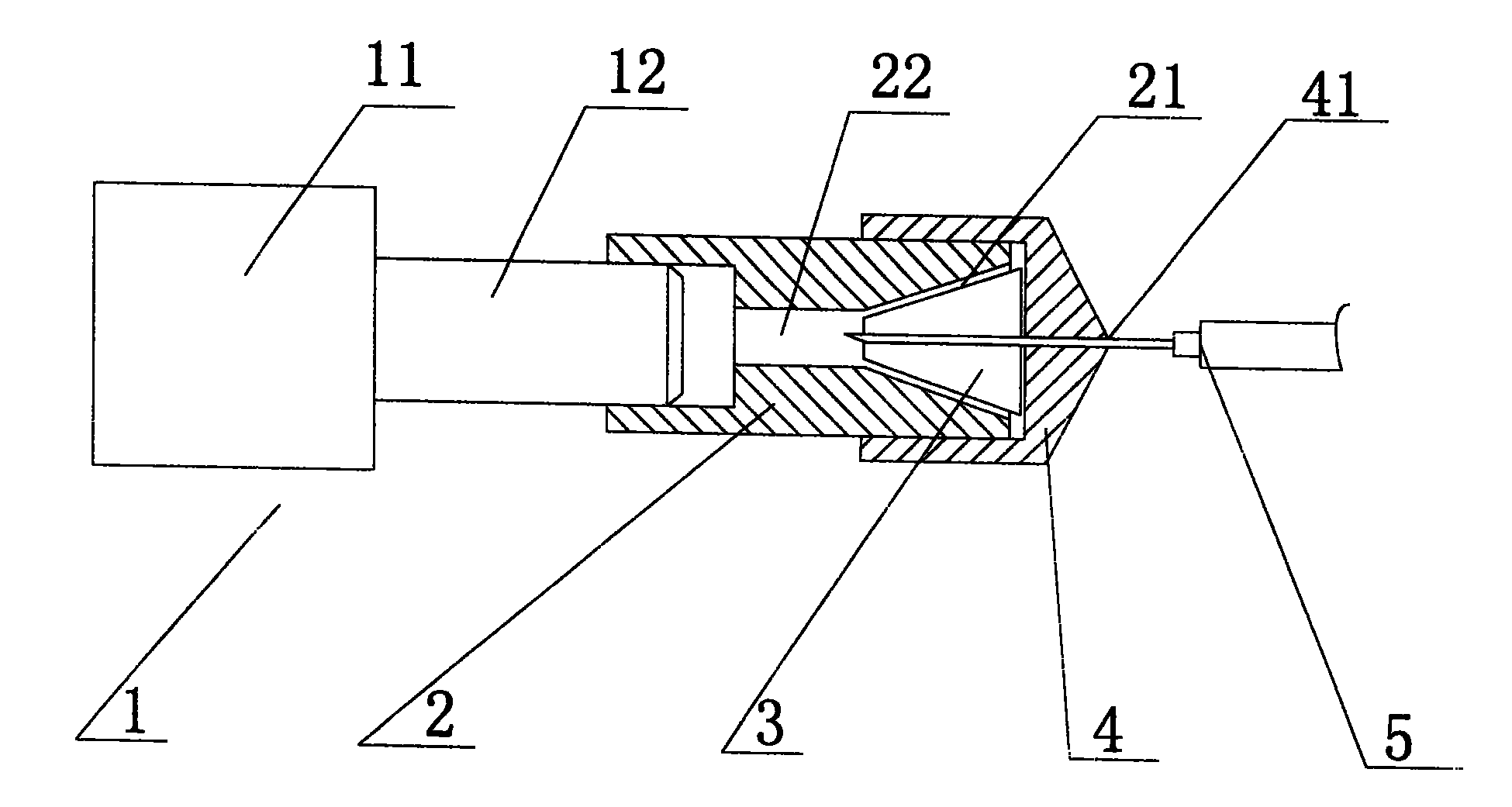

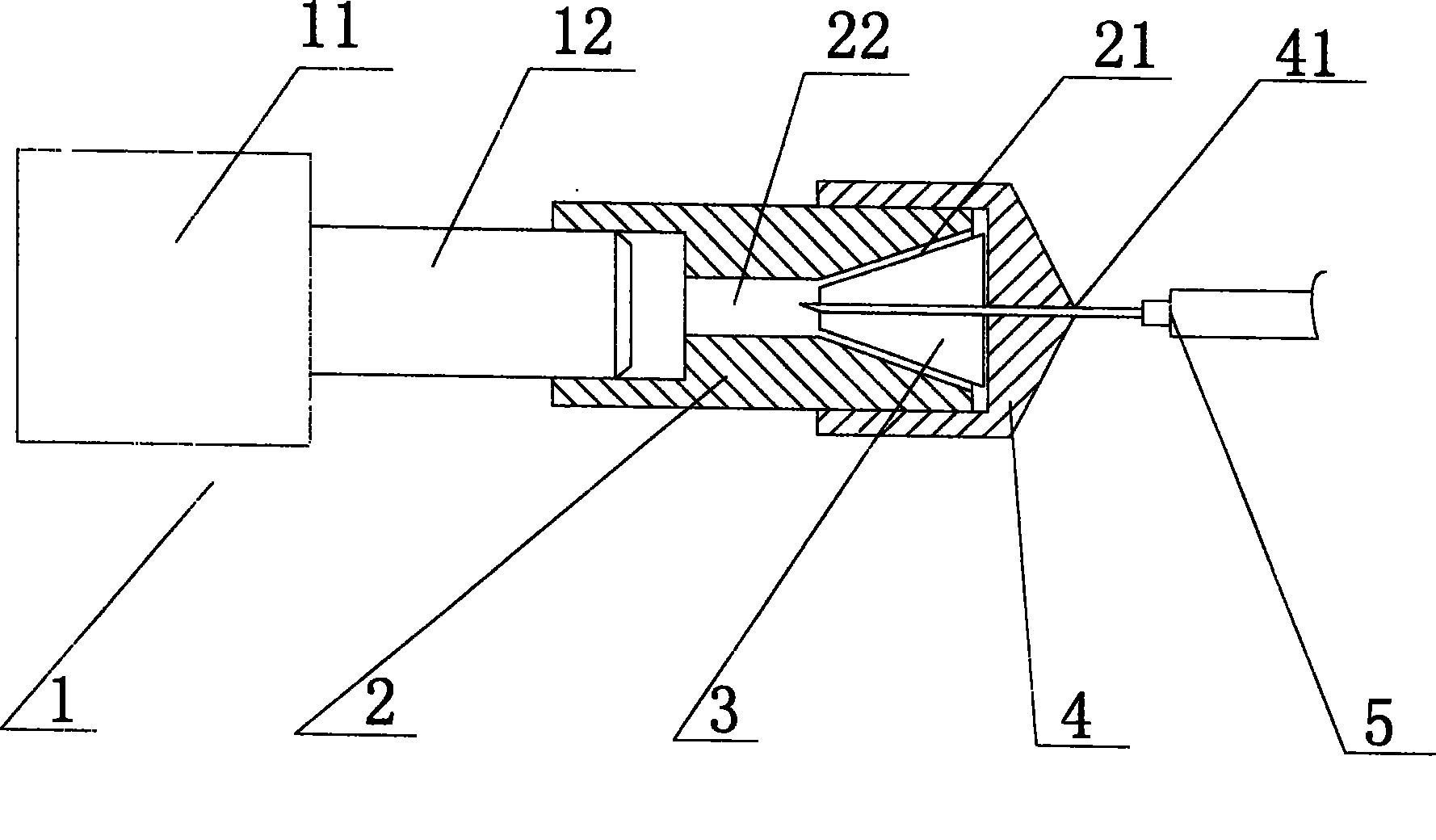

[0014] see figure 1 , the present invention below 0.4mm needle tube quick clamp, including coupling rod 1, locking body 2, two locking blocks 3 and locking cap 4.

[0015] The coupling rod 1 is composed of a rod seat 11 and a cylindrical rod body 12 connected on the rod seat, and the rod body is provided with an external thread for connecting with a locking body.

[0016] The locking body 2 is a cylindrical structural member, one end of which is provided with an internal thread to be threadedly connected with the rod body 12 of the coupling rod, and the other end is provided with an external thread and a tapered groove 21 for accommodating two locking blocks is provided at its front end , there is a small hole 22 that allows the measured needle tube to go deep into the bottom of the groove.

[0017] Two locking blocks 3 are two semi-cones, and the two semi-cones are combined to form a whole cone and are arranged in the tapered groove 21 at the front end of the locking body 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com