Dry system for drying straw

A drying system and straw technology, applied in drying solid materials, drying gas arrangement, solar heating system, etc., can solve the problems of dust, insect dung pollution and rain, covering a large area, and cannot meet the needs of industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

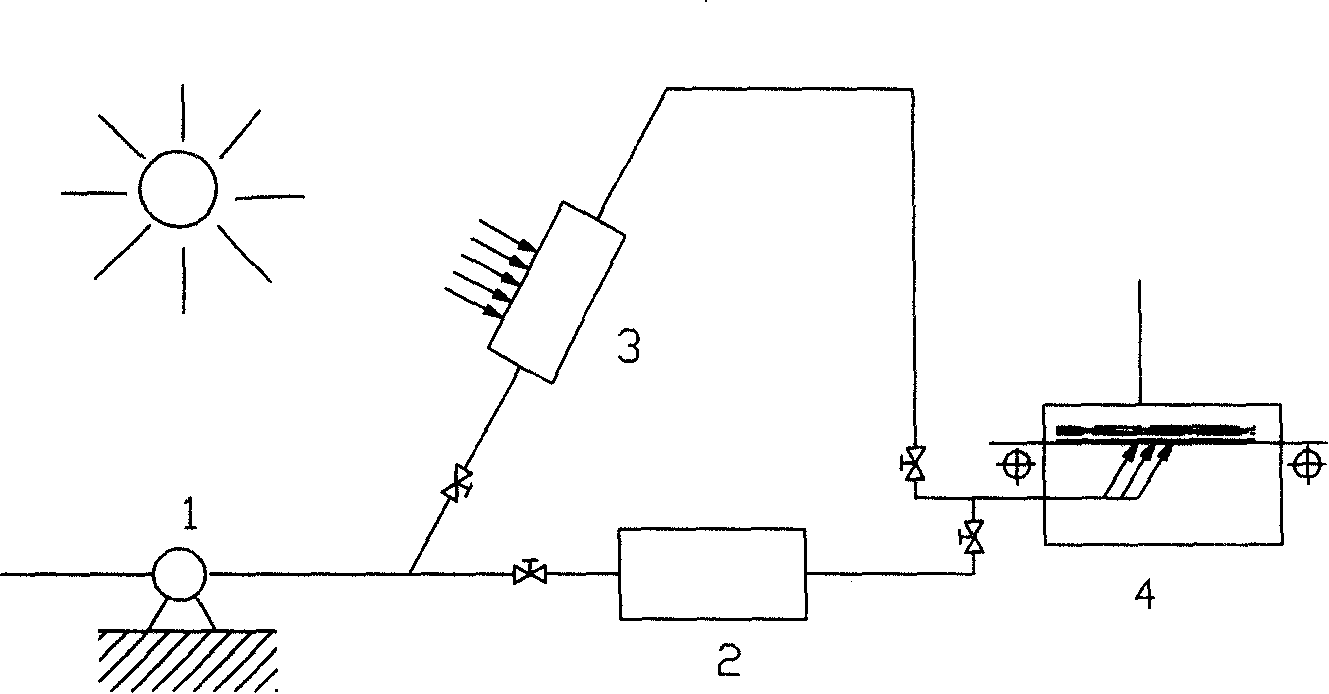

[0011] Such as figure 1 The drying system for drying stalks shown includes a tubular air heat collector 3, a single-row mobile dryer 4, a blower fan 1 and an electric heating blower 2, and the blower fan 1 is connected to the air inlet of the tubular air heat collector. The air outlet of the air heat collector is connected with the air inlet of the single-row mobile dryer, and the electric heating fan is also connected with the air inlet of the single-row mobile dryer. It also includes a temperature control device, the temperature control device is respectively electrically connected with the fan and the electric heating fan, and the temperature measuring part of the temperature control device is installed in the body of the single-row mobile dryer.

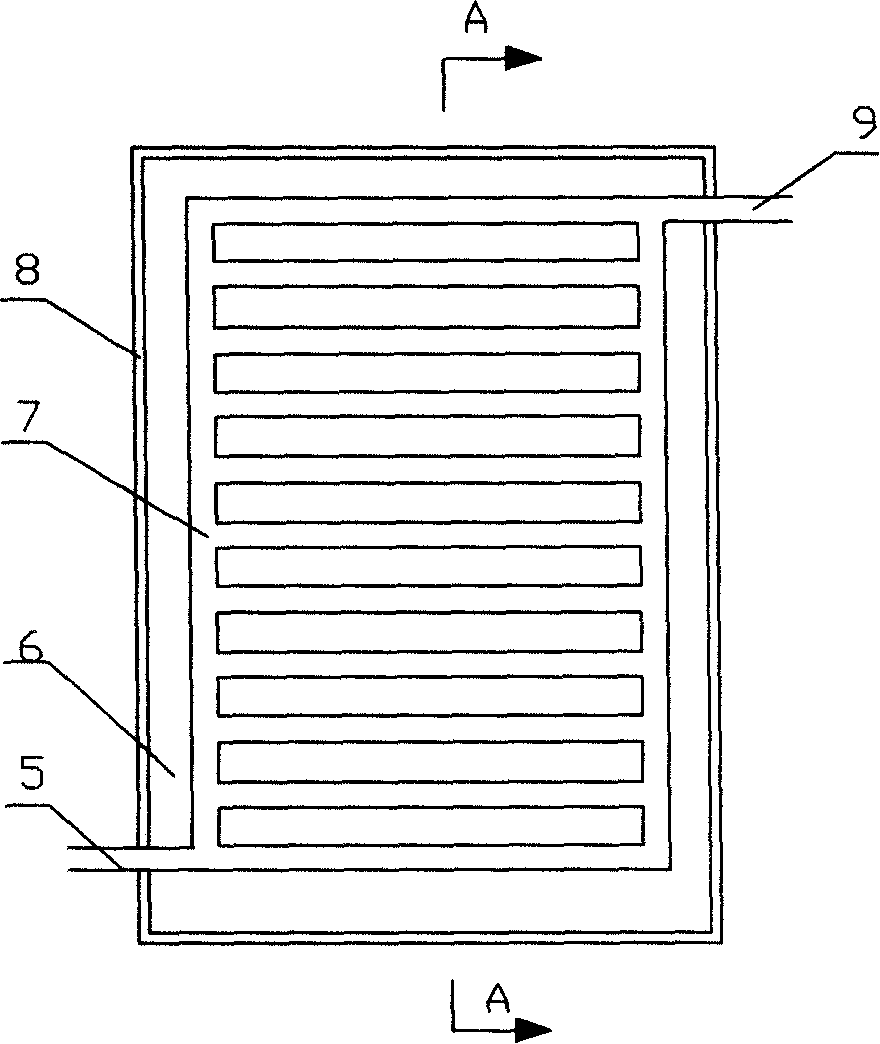

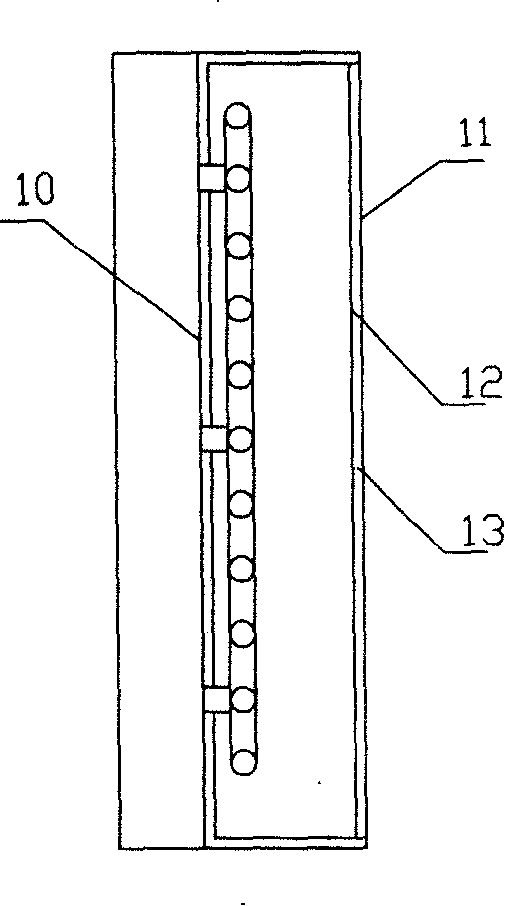

[0012] Such as figure 2 , image 3 As shown, the tubular air collector includes a cavity composed of an insulating layer 10 and double-layer insulating glass, a reflective layer 6 is attached to the insulating layer, and an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com