Air/fuel ratio control device for internal combustion engine

一种控制装置、空燃比的技术,应用在发动机控制、燃料喷射控制、电气控制等方向,能够解决性能变差、转矩变动增加、驾驶性能差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

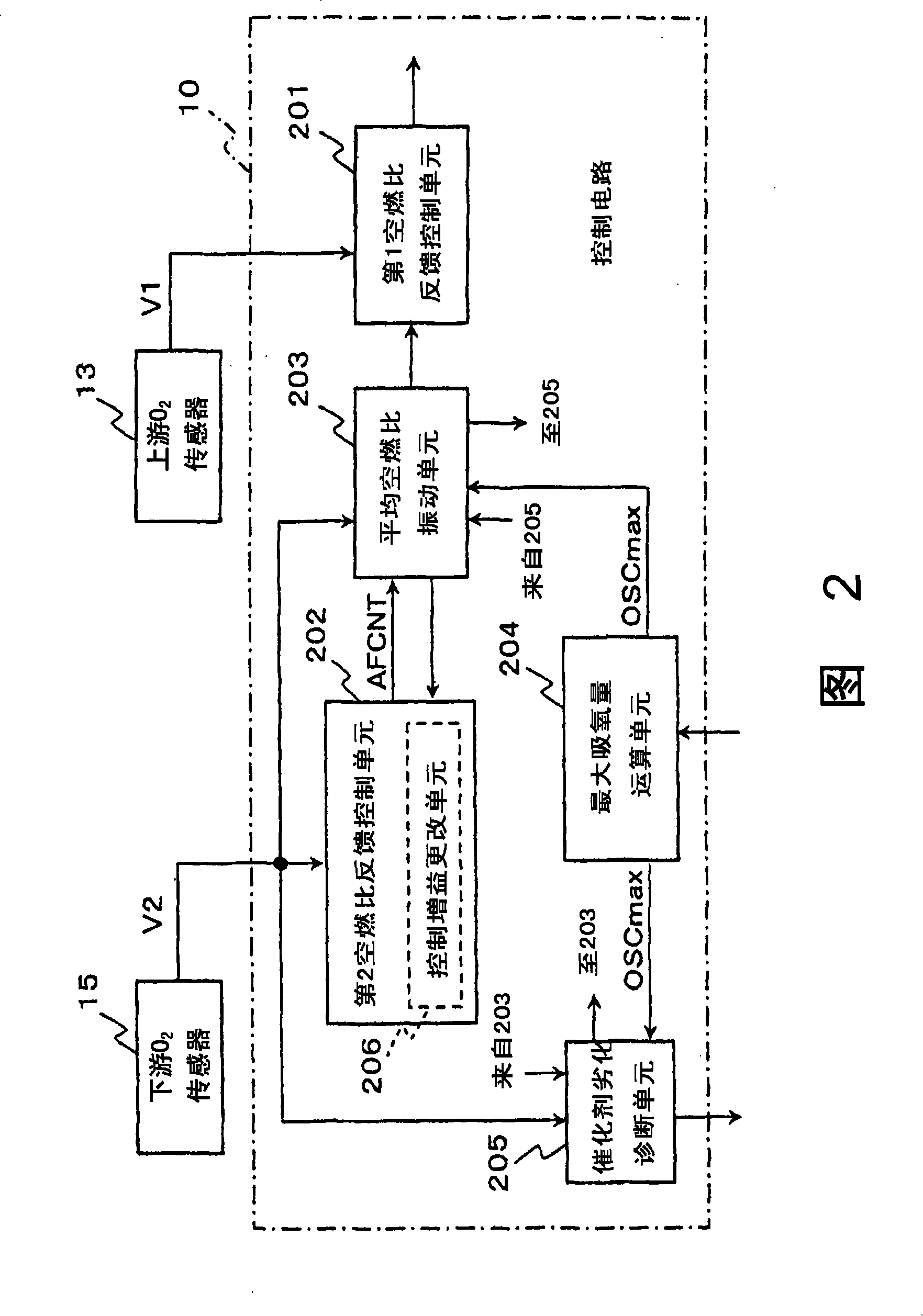

[0061] figure 1 It is a configuration diagram schematically showing an air-fuel ratio control device for an internal combustion engine according to Embodiment 1 of the present invention.

[0062] figure 1 Among them, an airflow sensor 3 is provided in an air intake passage 2 of a body 1 constituting an internal combustion engine (engine). The air flow sensor 3 has a built-in hot wire for directly measuring the intake air volume of the main body 1, and generates an output signal (analog voltage) proportional to the intake air volume. The output signal of the airflow sensor 3 is supplied to a multiplexer type analog-to-digital converter 101 in a control circuit 10 composed of a microcomputer.

[0063] The main body 1 is provided with a distributor 4 associated with ignition control of a plurality of cylinders, and the determiner 4 is provided with crank angle sensors 5 and 6 . One crank angle sensor 5 generates reference position detection pulses every 720 degrees in terms ...

Embodiment approach 2

[0364] Furthermore, in the first embodiment, the average air-fuel ratio vibration unit 203 performs the vibration processing based on the period counter Tmr, but may also perform the vibration processing based on the estimated value of the oxygen absorption amount (estimated oxygen absorption amount OSC).

[0365] Below, refer to figure 1 and Figure 2 and Figure 28 ~ Figure 31 , to describe Embodiment 2 of the present invention in which vibration processing based on the estimated oxygen uptake OSC is performed. At this time, only the arithmetic processing of the average air-fuel ratio vibration unit 203 (refer to Figure 6 ), the overall composition and other functions of the air-fuel ratio control device of the internal combustion engine are the same as those described above.

[0366] Figure 28 is a flow chart showing the processing operation of the average air-fuel ratio vibration unit 203 according to Embodiment 2 of the present invention, and Figure 6 The same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com