Reciprocating oscillation machine sample workpiece mounting and fixing device

A fixed device and reciprocating technology, which is applied in the direction of shaking/oscillating/vibrating mixers, preparation of test samples, mixers, etc., can solve the strict restrictions on sample placement, the inability to exert the fixing effect, and the increase in the use cost of the oscillator To achieve the effect of improving the freedom of sample placement, easy production and maintenance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

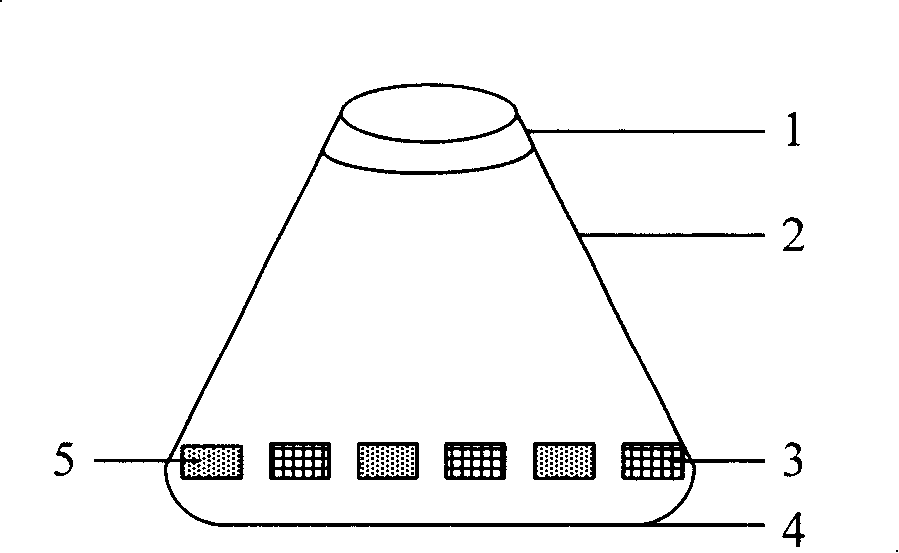

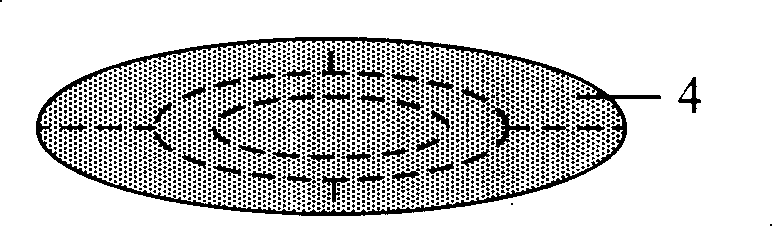

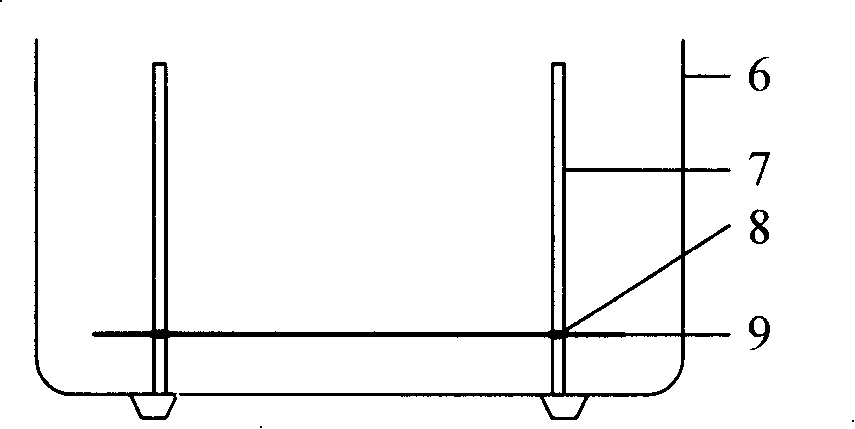

[0024] Such as Figure 1-5 As shown in the figure, 1 in the figure is a high-elastic elastic band or the mouth of the bag made of tether, 2 is the wall of the bag made of cloth with a tight belt, 3 is the B side of the two-piece gluing button, and 4 is the bag of the bag. The bottom of the bag (made of the A surface of the self-contained fastener), 5 is the A surface of the self-contained fastener, 6 is the reciprocating oscillator, 7 is the vibration frame in the oscillator, 8 is the support plate and the oscillator support rod The fixed buckle, 9 is an oscillator supporting plate, covered with the B side of the mother-in-law sticky buckle above it.

[0025] A reciprocating oscillator sample placement and fixing device, including a supporting plate 9, the supporting plate 9 is placed on the oscillation frame 7 of the oscillator 6, the oscillation frame 7 is connected with the oscillation source of the oscillator 6,

[0026] The upper surface of the supporting plate is fixed ...

Embodiment 2

[0037] First, improve the supporting board of the oscillator, use the original supporting board (or use wood boards and other materials to make it according to the specifications and sizes), and fix the B side of the mother-in-law gluing on the front side of the supporting board, that is, the upward side, such as Figure 5 shown. Second, carry out the making of the container containing bag, such as figure 1 , the bottom of the bag ( figure 2 ) is made of the A side of the mother-in-law gluing, so that it can be adsorbed to the B side of the gluing on the supporting plate, so as to realize the fixing of the container bag; the bag wall of the bag ( figure 1 4) Use cloth and elastic bands to make the bag wall, so that the bottom of the bag can be applied to containers of different volumes and shapes; the opening of the bag ( figure 1 1) Use a high-elastic elastic band or a tether to make the bag mouth, which can also play a fixed role on the premise that the container can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com