Robot system able to secure worker safety

A robot system and robot technology, applied in the field of robot systems, can solve problems such as cost increase, threat to operator safety, and robot system cost increase, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

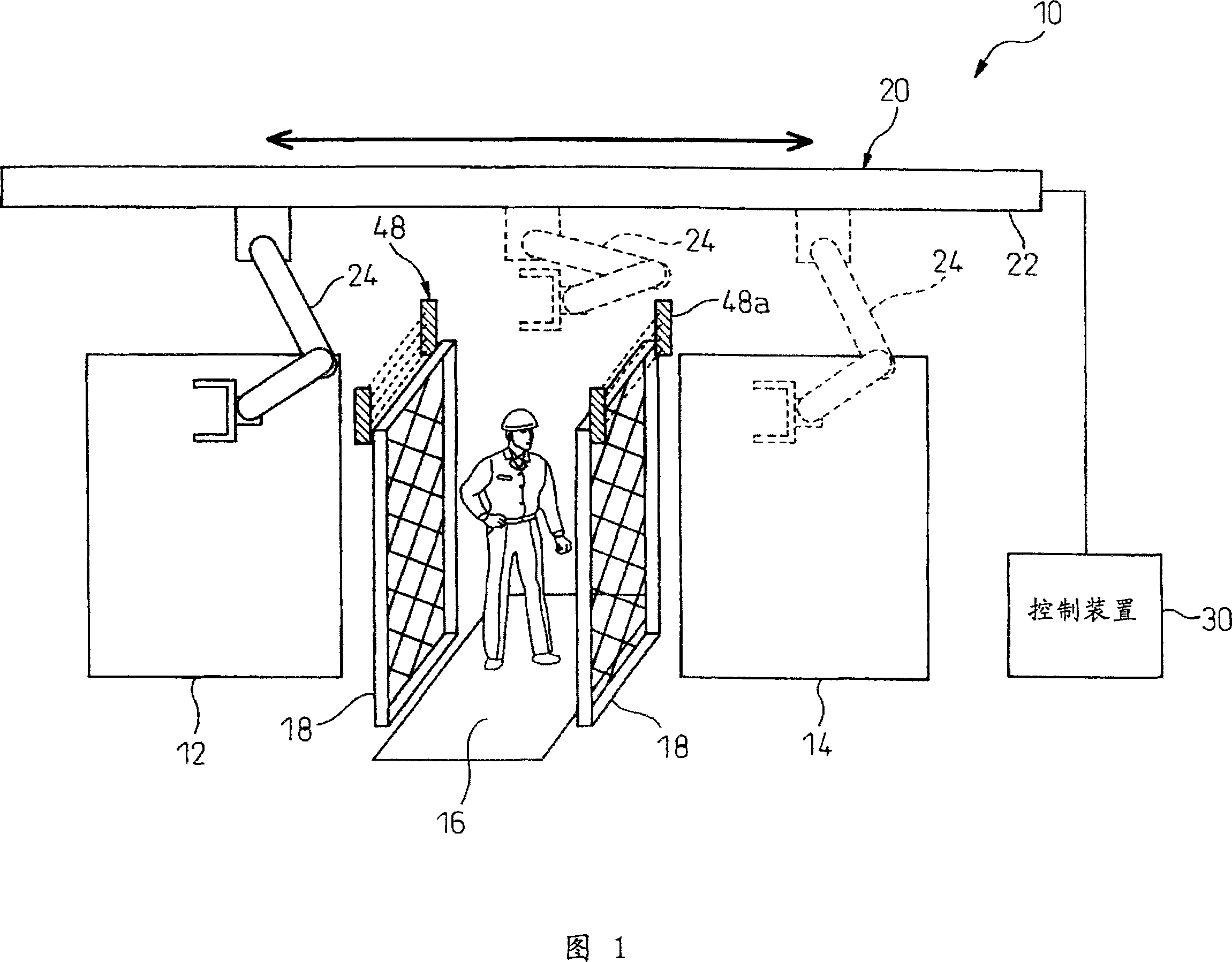

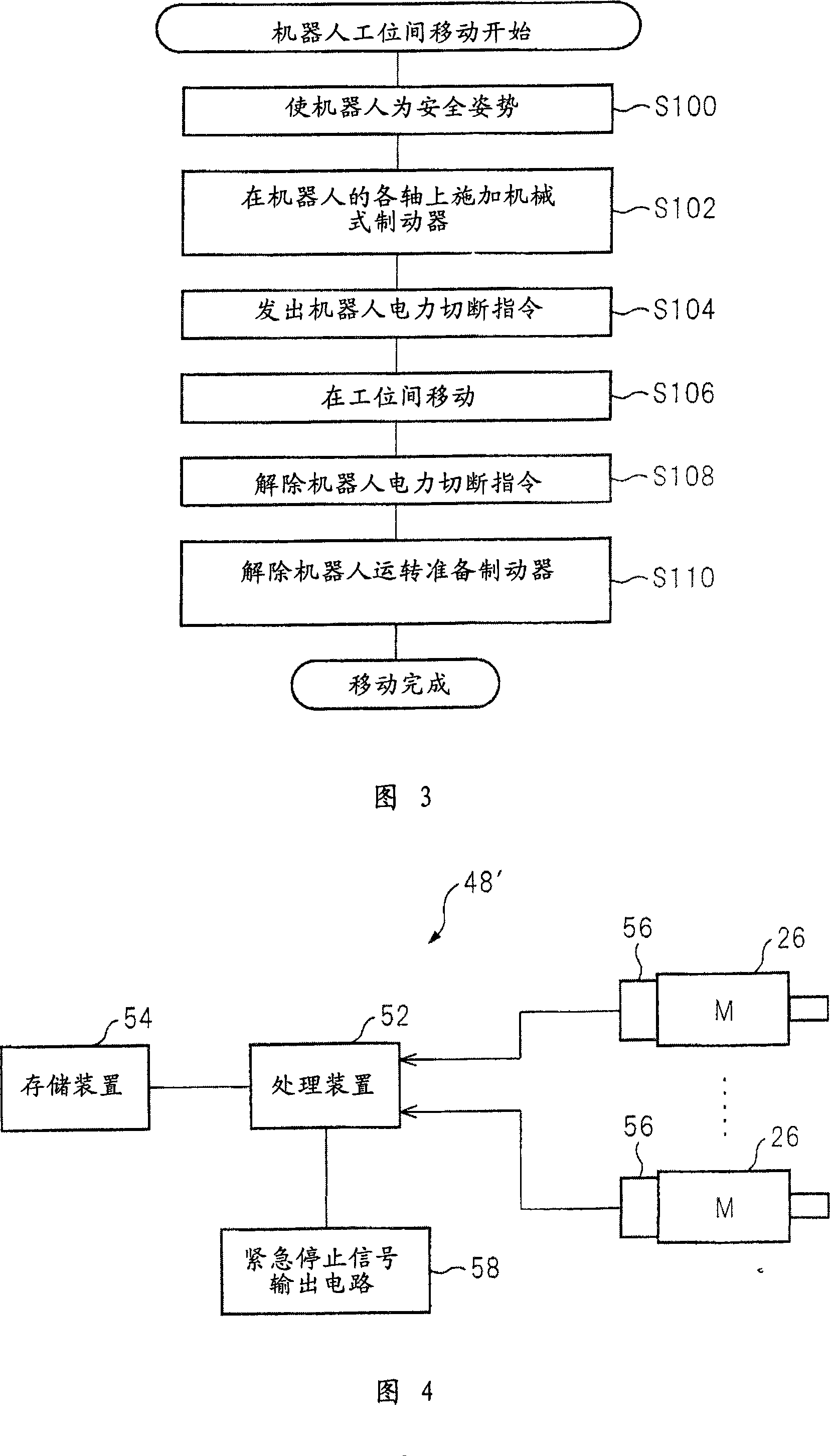

[0024] Hereinafter, embodiments of the robot system of the present invention will be described with reference to the drawings.

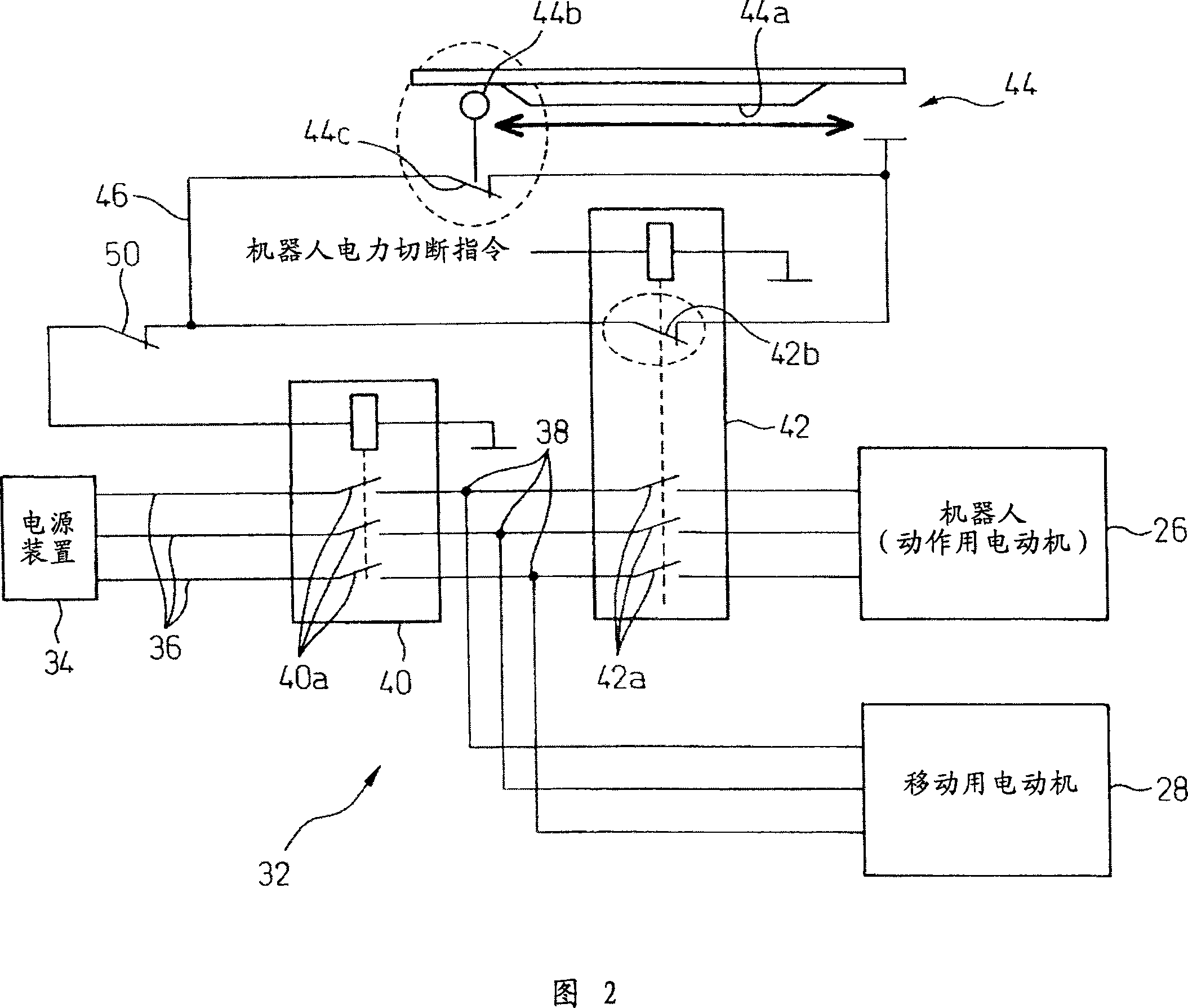

[0025] In the robot system 10 of the present invention, a plurality of stations including a first station 12 and a second station 14 are provided. In addition, between the first station 12 and the second station 14, there is an operator channel 16 for the operator to pass through for the transportation of materials or the maintenance of the machine. The workstations 12, 14 are separated by an operator access 16. The stations 12 and 14 are, for example, areas where workpieces are machined by machine tools such as machining centers, and pallet arrangement areas where workpieces before or after machining are placed. In addition, above the workstations 12, 14, a crane frame 20 extending across a plurality of workstations is provided. A traveling path 22 such as a traveling rail extending in the horizontal direction is provided on the crane frame 20 alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com