Climbing level robot

A robot and pole-climbing technology, applied in the field of pole-climbing robots, can solve problems such as the inability of the robot to work and the limitation of working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

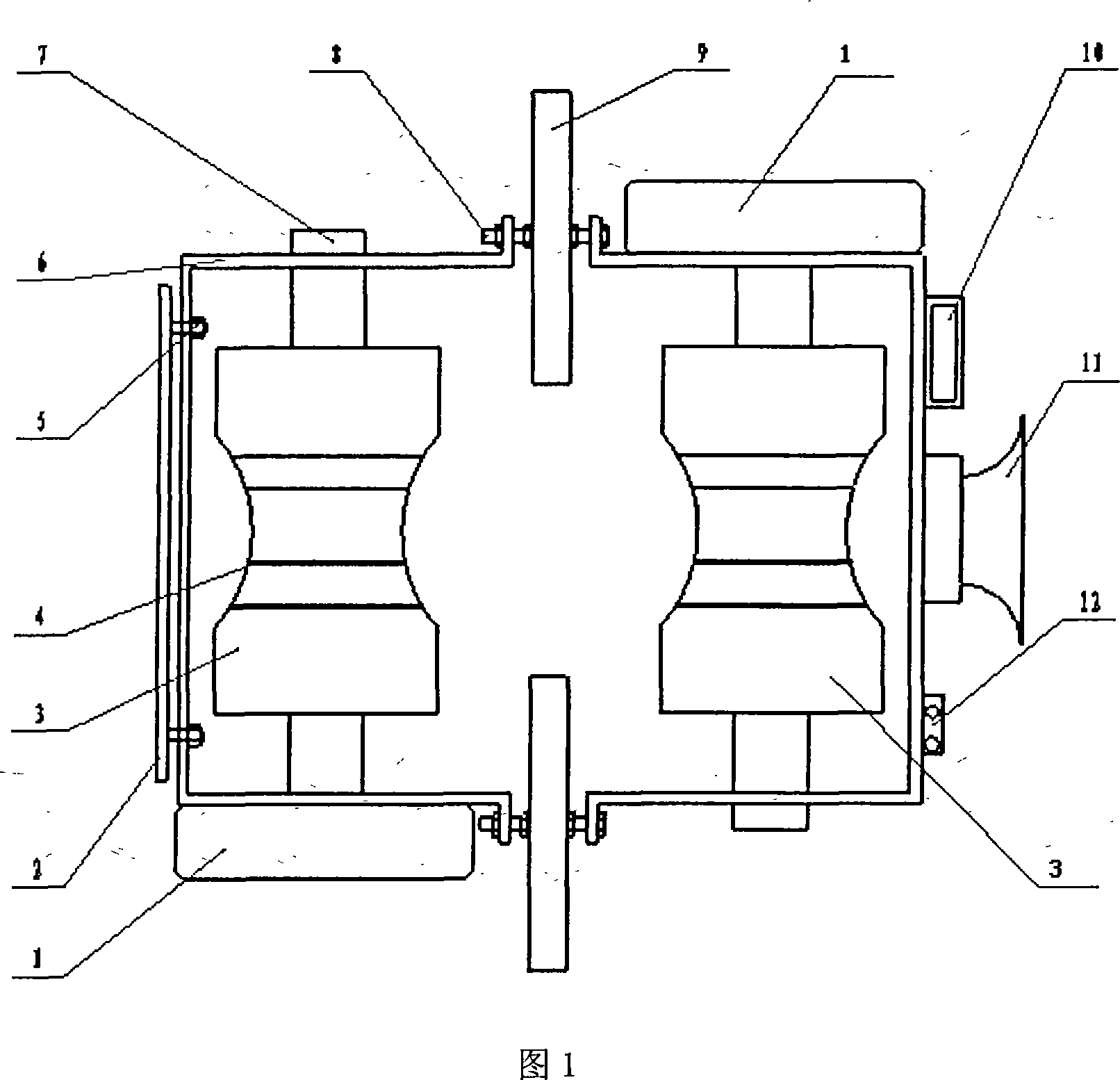

[0011] Embodiment: structure as shown in Figure 1, support 6 is that two small supports are connected by threaded connecting rod 8, and two stepper motors 1 are respectively fixed on both sides of the support, stepper motor 1 and roller 3 shaft, and drive the roller 3 to rotate, the roller 3 is wound with a rubber belt 4, to increase the friction between the roller and the bar, and prevent slipping, the roller 3 cooperates with the bracket 3 through the sleeve 7. The orienting roller 9 is fitted on the bolt link 8, and the orienting roller 9 and the roller 3 surround the climbed bar jointly to realize the climbing action. The control system circuit board 2 is fixed on the bracket through the circuit board fixing frame 5, the control system circuit board 2 is connected with the stepper motor 1, the elastic switch 10, the small horn 11 and the gray scale sensor 12, and the control system circuit board 2 is controlled by the single chip microcomputer Stepper motor 1, elastic swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com