Reversal preventing equipment

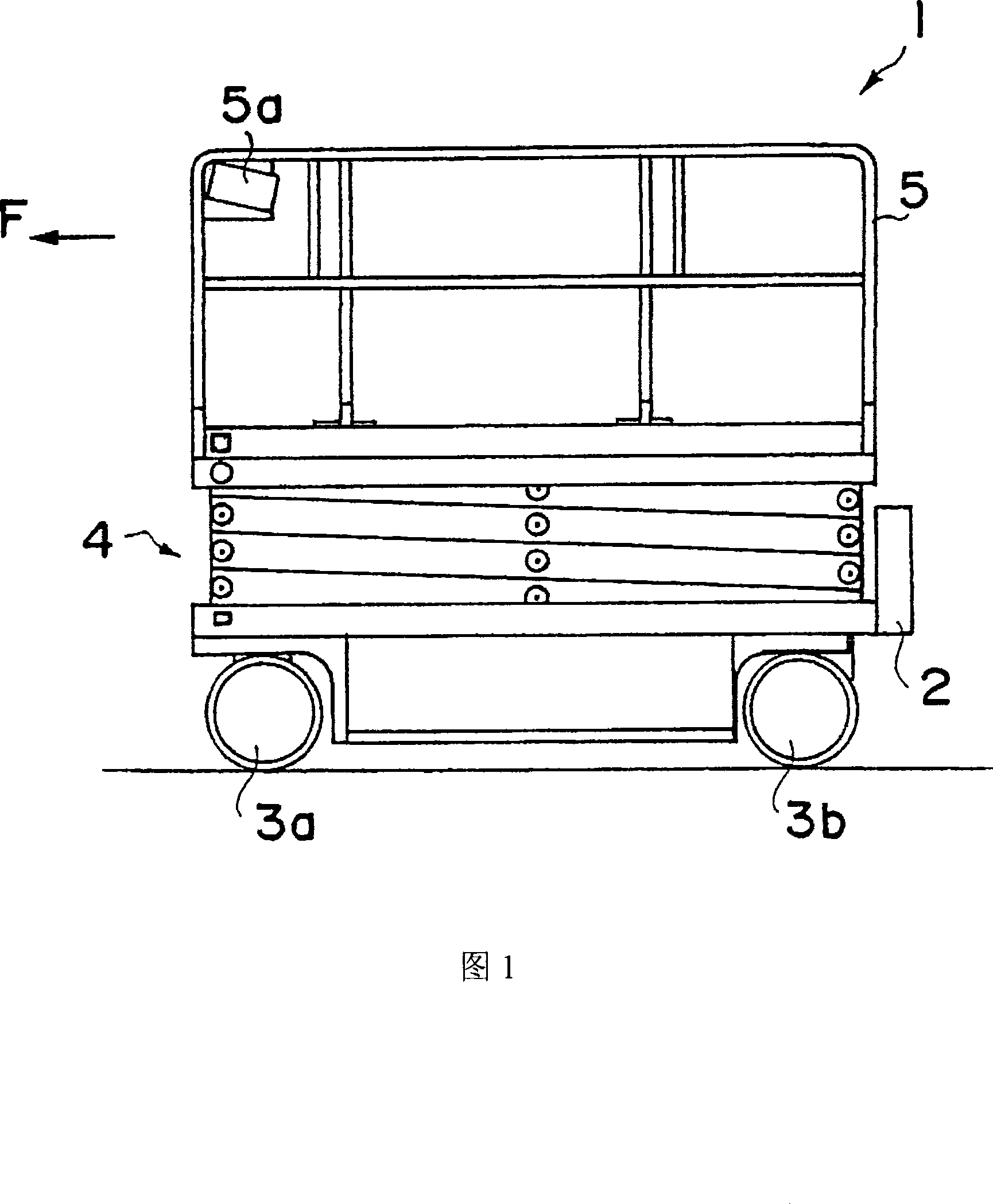

一种设备、车体的技术,应用在起重设备安全装置、提升装置等方向,能够解决颠倒防止板易被卡住、花费大量时间、易出现缝隙等问题,达到防止缝隙、减少部件数量、确保高空作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

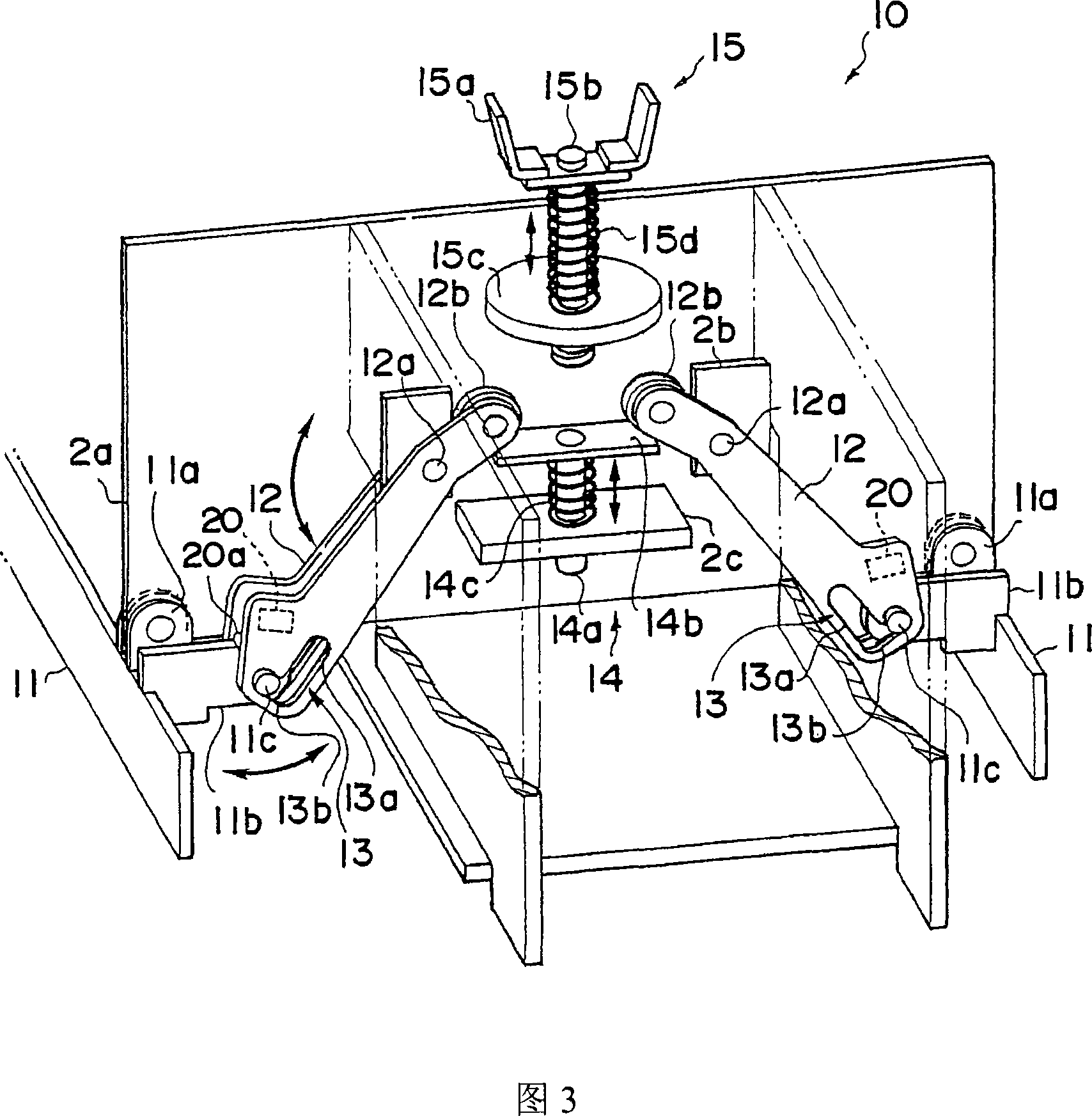

[0029] First, a first embodiment of an inversion preventing device according to the present invention will be described with reference to FIGS. 3 to 9 . As shown in Figure 3, the above-mentioned upside-down prevention device 10 includes a pair of upside-down prevention plates 11 installed on the vehicle body 2, a pair of left and right driving arms 12, and a first bracket on the unfolding operation part 14 and the scissor lift 4. 8 is installed on the storage operation part 15.

[0030] The inversion preventing plate 11 is composed of an elongated plate-shaped member extending in the vehicle front-rear direction, and has a shaft coupling portion 11a formed inside the inverting preventing plate 11 and extending upward, and a swing portion 11b extending inwardly. The shaft coupling portion 11a of the above-mentioned inversion preventing plate 11 is freely swingably mounted on the plate mounting portion 2a formed below the left and right sides of the vehicle body 2 . In addition...

Embodiment 2

[0047] Next, a second embodiment of an upside-down preventing device according to the present invention will be described with reference to FIG. 11 . Here, the same symbols are used for the same parts as those in the first embodiment, and detailed explanations are omitted. In the first embodiment, when the inversion preventing plate 11 is unfolded, the head 12b of the driving arm 12 is pushed up by the unfolding operation part 14, so that the outer part of the driving arm 12 is swung downward, but in the inversion of the second embodiment, In the arresting device 10', an expansion spring 14' is used. One end of the above-mentioned expansion spring 14' is fixed on the driving arm mounting part 2b of the vehicle body 2, and the other end is fixed on the outside of the shaft coupling hole 12a of the driving arm 12, so that the outer part of the driving arm 12 is pulled inward and swings downward. Therefore, when the lifting cylinder 7 starts to extend the operation to extend the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com