Eccentric electric ball valve

A technology of electric ball valves and eccentric balls, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of high power and large rotating torque of electric ball valves, and achieve the effects of improving service life, reducing rotating torque, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

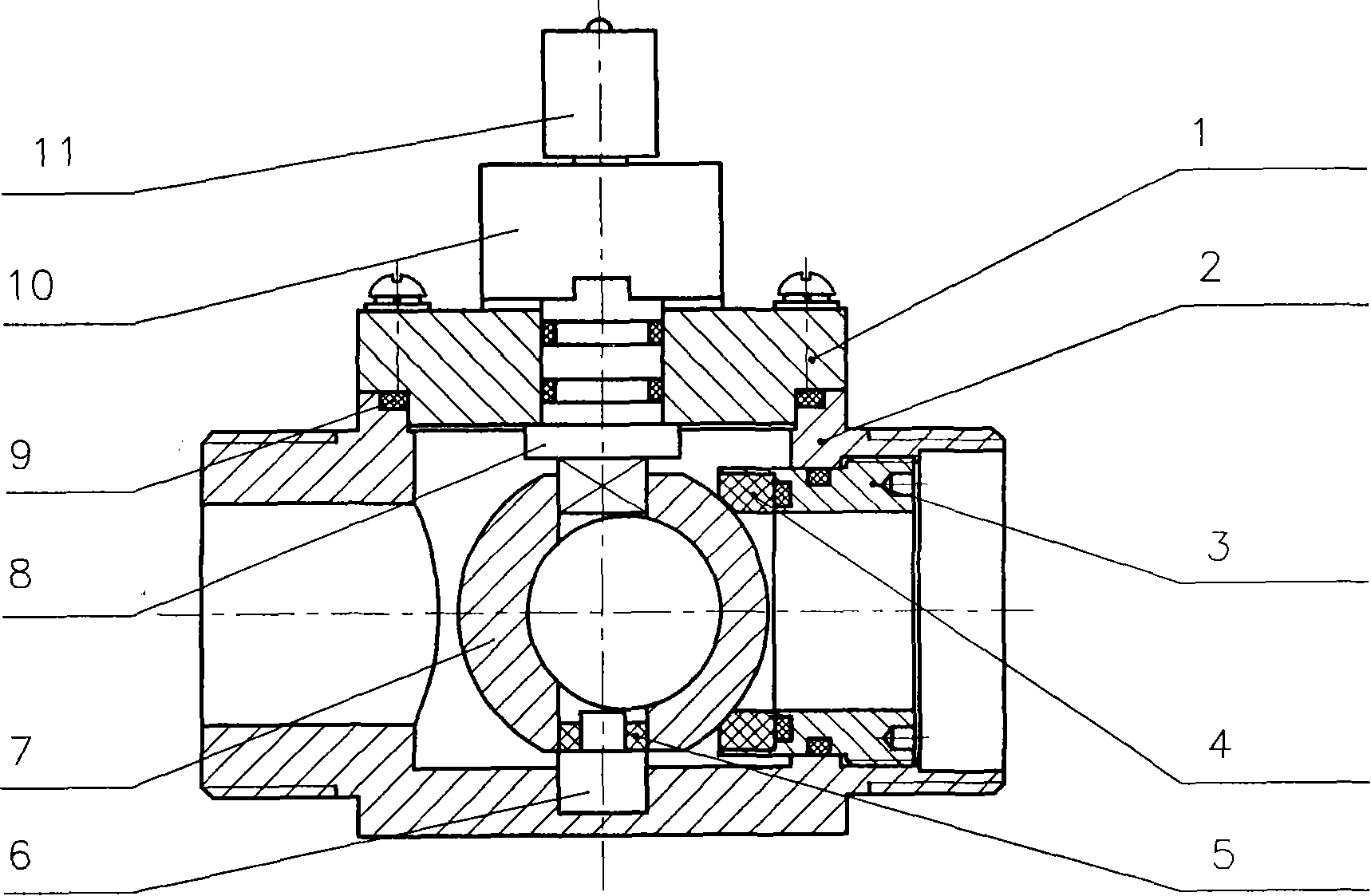

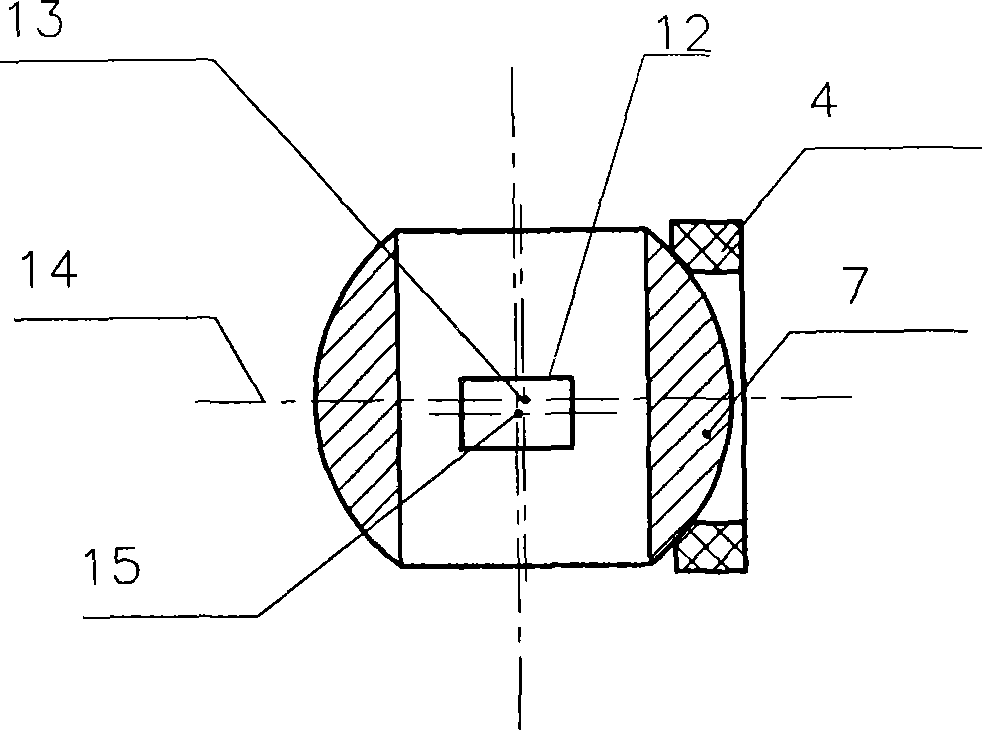

[0010] Such as figure 1 As shown, an eccentric electric ball valve described in this embodiment includes a valve cover 1, a valve body 2, a sealing seat 3, a sealing ring 4, a supporting sleeve 5, a supporting shaft 6, an eccentric ball 7, a valve stem 8, and an O Form ring 9, reducer 10, motor 11, reducer 10 is connected with valve stem 8, the head of valve stem 8 is square and matches with eccentric hole 12 opened on the upper part of eccentric ball 7, so that valve stem 8 drives The eccentric ball 7 rotates to form a cam-like movement structure with the valve stem 8. The lower end of the eccentric ball 7 is supported and positioned by the support shaft 6. A seal for adjusting the pressing force is provided between the valve body 2 and the eccentric ball 7. Seat 3 and sealing ring 4. At this time, the eccentric ball 7 ensures that the water or gas medium does not leak by pressing the sealing ring 4 , and the compression force between the eccentric ball 7 and the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com