Full-automatic current limiting type negative pressure-free pipe network Pressure-superposed water supply equipment

A superimposed water supply, fully automatic technology, applied in the direction of electric fluid pressure control, water supply device, water supply main pipeline, etc., can solve the problems of bad impact on the pipe network, unstable changes in the flow state in the pipe network, secondary pollution and other problems , to avoid adverse impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

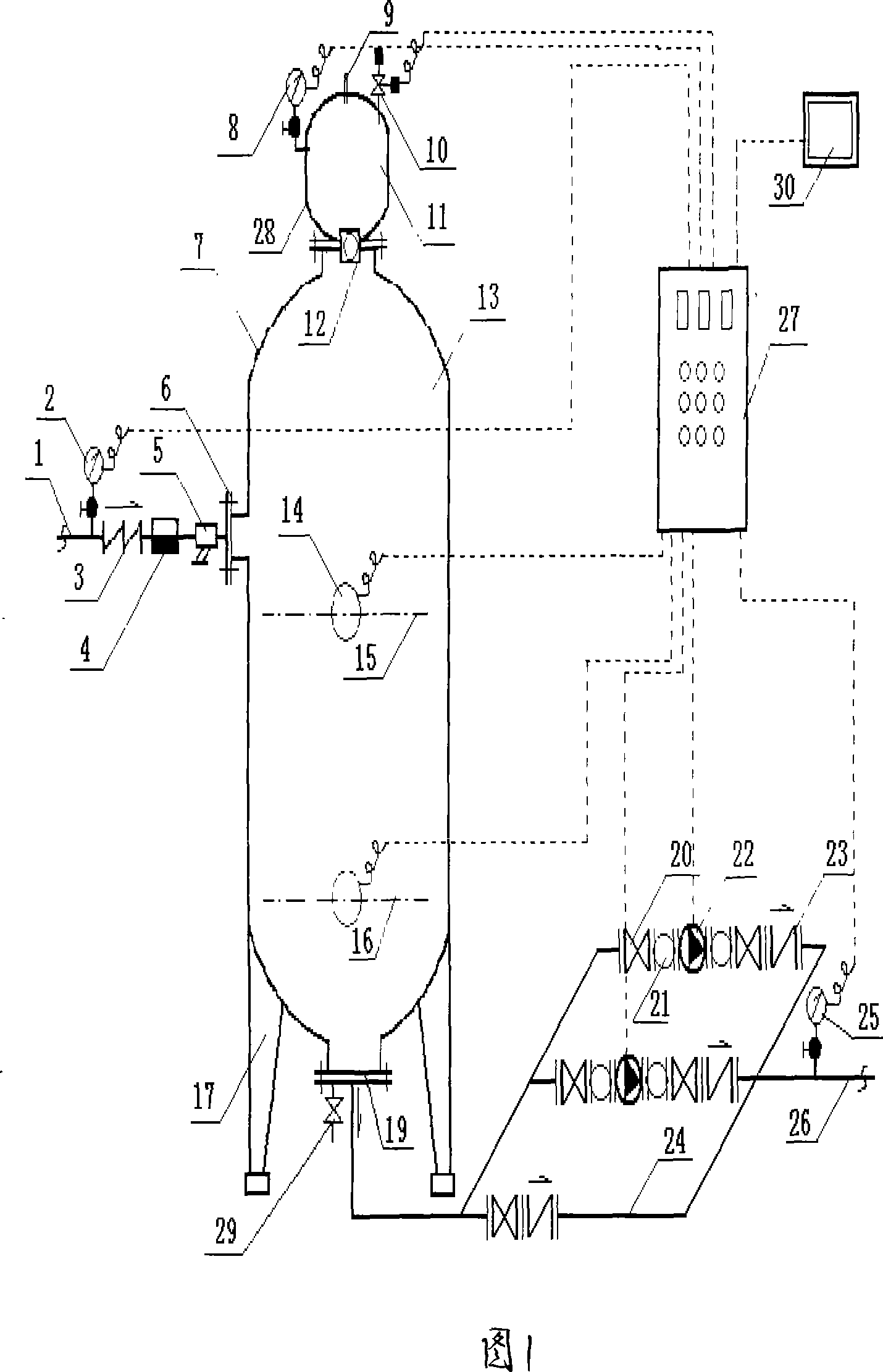

[0049] Embodiment 1, see Fig. 1, install the water inlet pipe remote transmission pressure gauge 2 on the tap water inlet pipe 1, and then connect the backflow preventer 3, the water inlet side gas interrupter 4, and the filter 5 in sequence on the water inlet pipe, and filter The device 5 is connected with the steady flow regulator tank 7 through the pipeline, and the steady flow regulator water inlet flange 6 is installed at the connection end of the steady flow regulator tank 7, and the inner cavity of the steady flow regulator tank 7 is a flow regulating device. Device water cavity 13, fix the steady flow regulator support 17 at the bottom of the steady flow regulator tank body 7, install the cleaning blowdown valve 29 at the water outlet at the bottom of the steady flow regulator tank body 7, The connection at the bottom of 7 is installed with the water outlet flange 19 of the steady flow regulator; after the water pump unit is connected in parallel with the bypass pipe 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com