Automatic paint spraying machine

A technology of automatic paint spraying machine and spray booth, which is applied in the direction of spraying device, coating, and surface coating liquid device, etc., which can solve the problems of greatly increased mold cost, low degree of automation, and long cycle, so as to save mold cost, The effect of high degree of automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

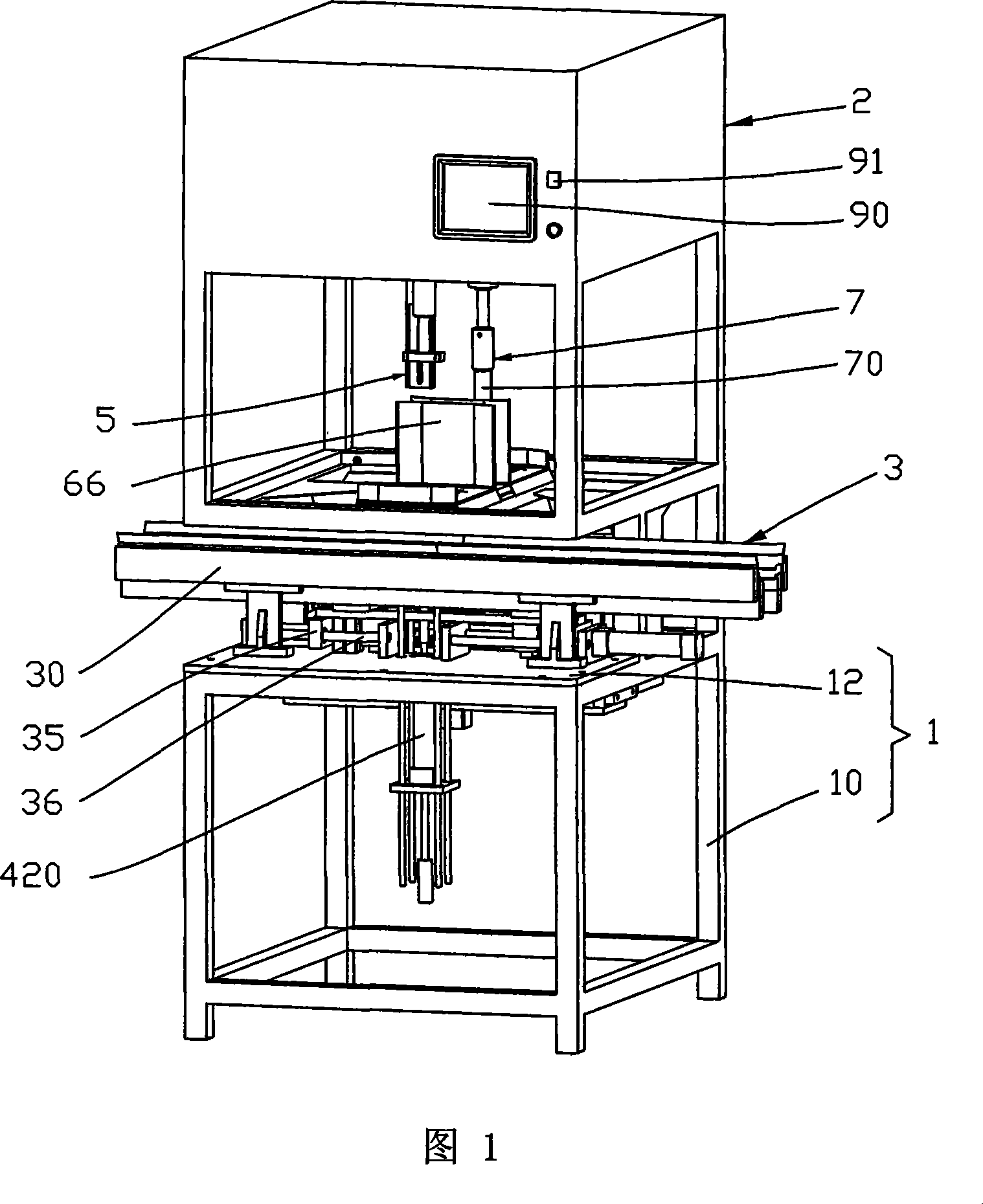

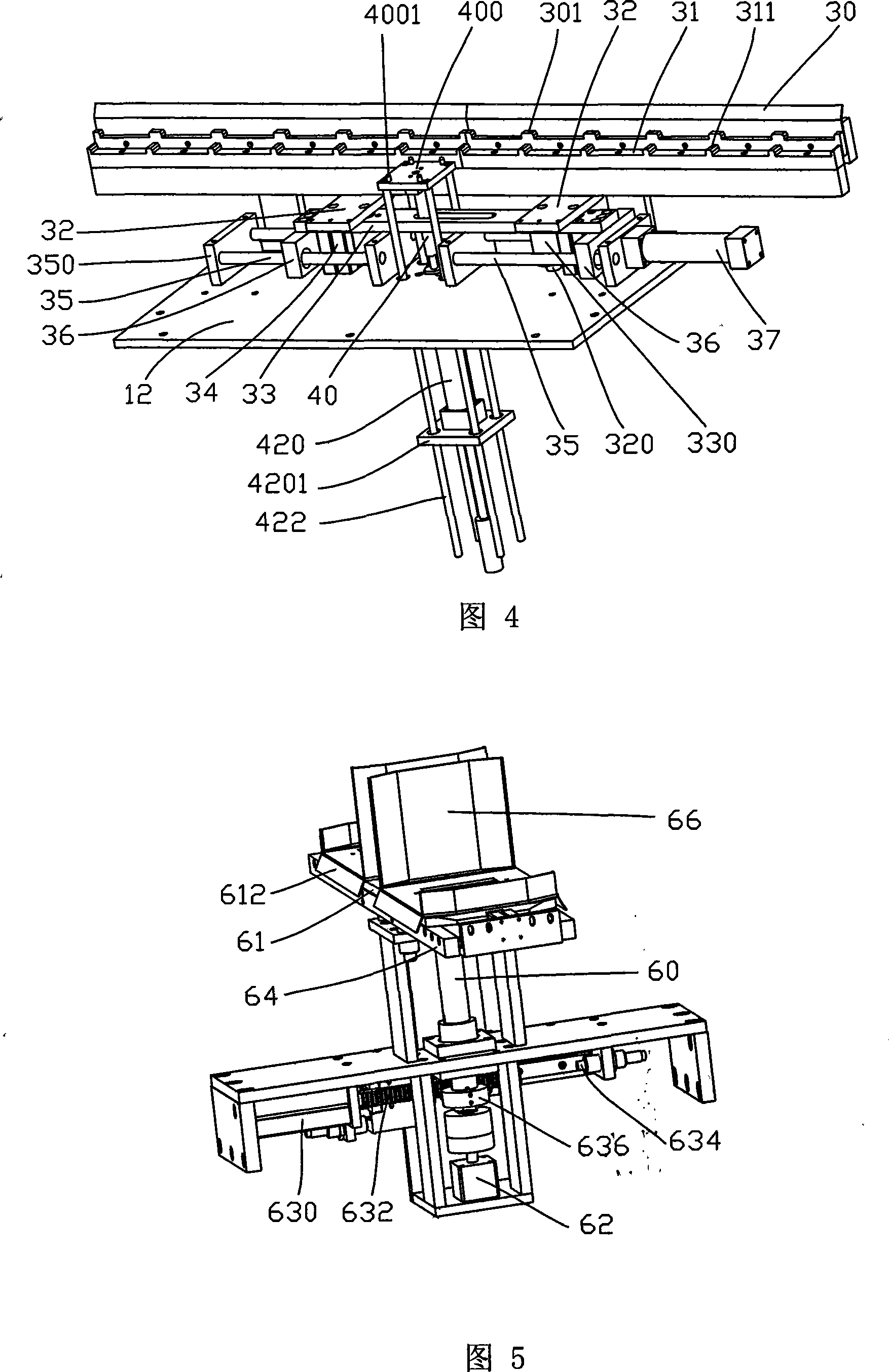

[0015] As shown in Figures 1 to 2, the present invention provides an automatic painting machine, including a machine platform 1, a paint spray booth 2 arranged above the machine platform 1, and a workpiece conveying device located on the machine platform 1 and below the paint spray booth 2 3. Mold setting device 4, paint spraying device 5, mold rotating device 6 provided with mold (not shown), mold washing device 7, sewage discharge device 8 and control system (not shown).

[0016] Wherein, the machine table 1 is a platform installed as other components, and mainly consists of a frame 10 and a platen 12 arranged on the top of the frame 10 .

[0017] Described spray booth 2 utilizes support 20 to be arranged on the top of machine platform 1, and it is a closed working chamber, and its internal area is divided into spray paint area and mold washing area, and described spray paint device 5 and mold wash device 7 are respectively located in spray paint. area and mold washing area....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com