Spilled stannum port with external L-shaped stannum export

A technology of tin outlet and overflow tin, which is applied in the field of tin outlet of tin furnace, can solve the problems of low work efficiency, easy to form false soldering of joints, unsuitable for large-scale batch processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

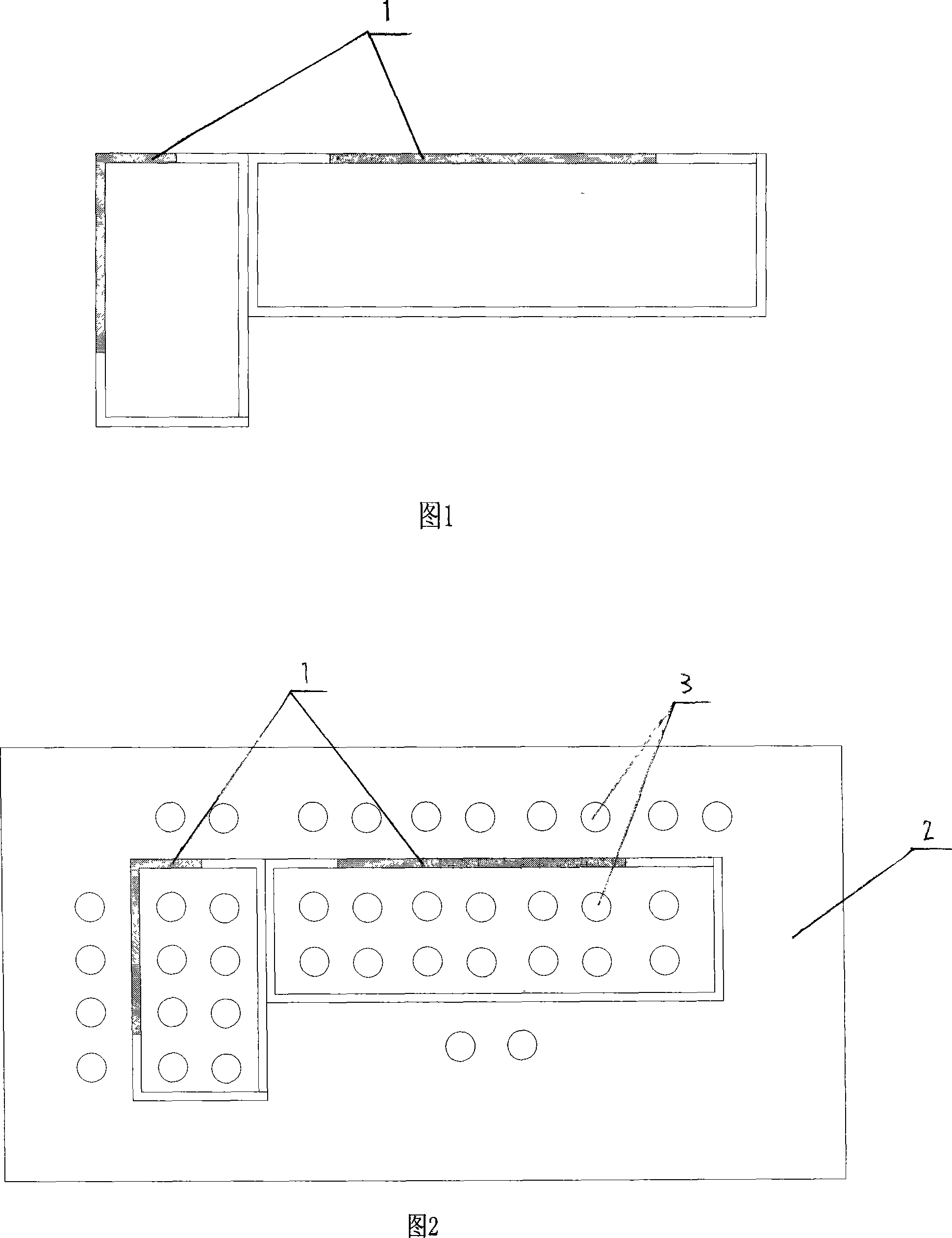

[0012] As shown in Figure 1, an L-shaped tin outlet with an overflow tin outlet is fixed and connected by two rectangular tin outlets to form an "L" shape, and the tin outlet outside the "L"-shaped tin outlet is provided with A tin overflow opening 1, which is a rectangular opening with a depth of 2-8 mm.

[0013] As shown in Fig. 2, the tin outlet described in the present invention is mainly used to distribute the electronic components 3 on the PCBA board 2 in an "L" concentration, and there are other electronic components adjacent to the tin outlet on the inner side of the "L" semi-enclosed structure. The device 3 exists, but there is no electronic component 3 on the outside or the distance from the tin outlet is relatively far.

[0014] When in use, place the PCBA board 2 at a predetermined position above the tin outlet, and keep a certain distance between the board plane and the tin outlet, generally controlled at 2-6 mm. The shape of the tin outlet can be determined acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com