Method for refining beta-methylnaphthalene by melting crystallization

A technology of melt crystallization and methylnaphthalene, which can be used in crystallization purification/separation, organic chemistry, etc., can solve the problems of long process, complicated equipment and operation, and achieve the advantages of low operating cost, simple equipment and process, and improved operating conditions for workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

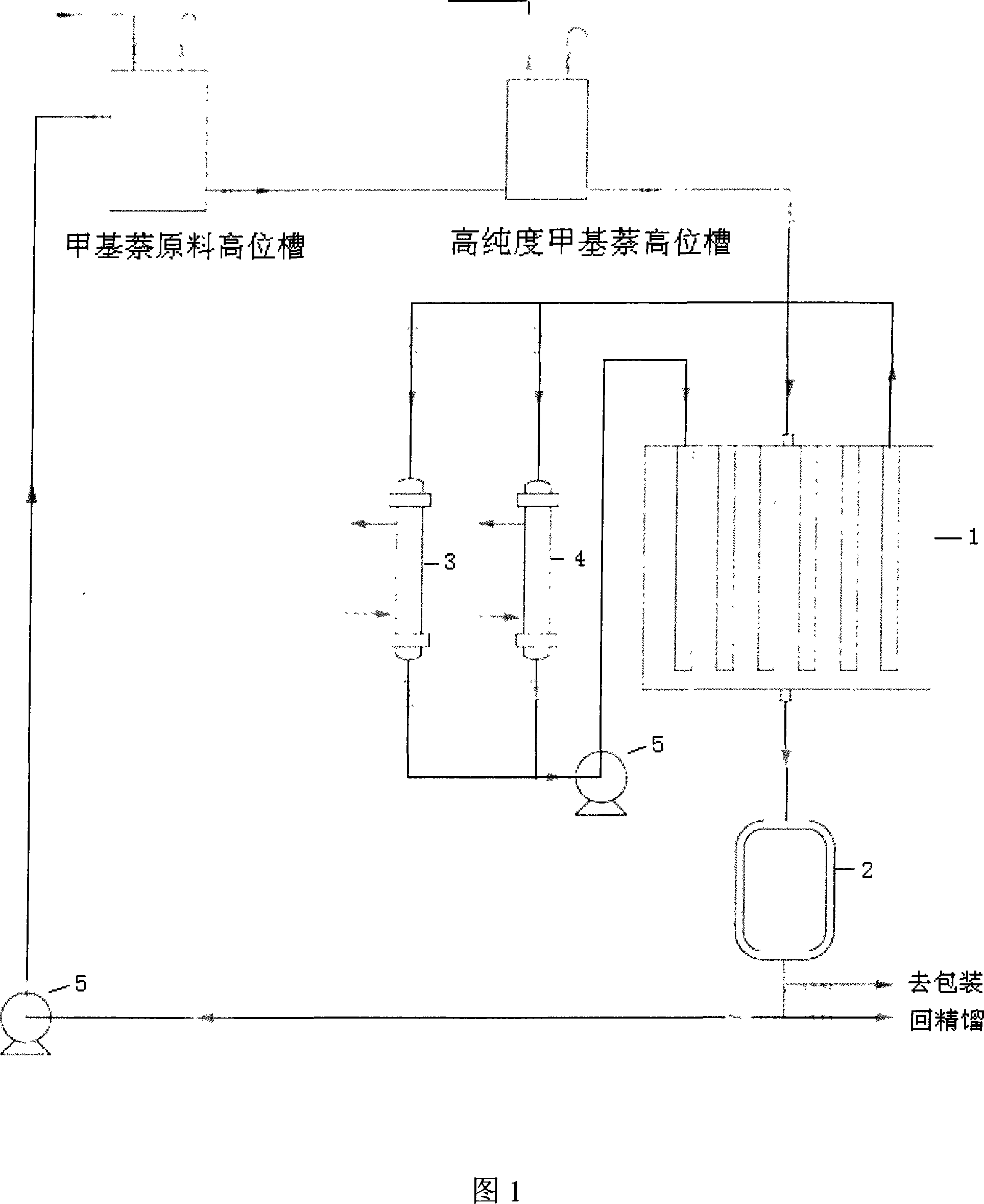

Image

Examples

Embodiment 1

[0025] The high-purity 98.1% β-methylnaphthalene was subjected to film-hanging operation at 0°C for 2 minutes, then the temperature of the crystallizer was raised to 15°C, and 75.0% of the β-methylnaphthalene raw material was heated to 25°C and then put into the crystallizer In the process, after allowing the crystal layer to grow for 1.5 hours, cool down at 2°C / h to crystallize and grow the crystal layer for another 3.5 hours. The thickness of the crystal layer is about 20 mm. The end temperature was 30°C, and the crystal was heated to 40°C to melt, and the purity by gas chromatography analysis was 98.06%. The melting amount of β-methylnaphthalene in the sweating operation is 40% by weight, and the sweating mother liquor is cyclically crystallized. The total crystallization yield was 64.6%.

Embodiment 2

[0027] The high-purity 97.1% β-methylnaphthalene was subjected to film-hanging operation at 5°C for 1 min, then the temperature of the crystallizer was raised to 20°C, and 85.6% of the β-methylnaphthalene raw material was heated to 34°C and then put into the crystallizer In the process, let the crystal layer grow for 2.5 hours, then cool down at 3°C / h to grow the crystal layer for another 5 hours, the thickness of the crystal layer is about 28mm, discharge the crystallization residual liquid and perform sweating operation, the heating rate is 2°C / h, sweating The end temperature was 31°C, and the crystal was heated to 41°C to melt, and the purity by gas chromatography analysis was 98.47%. The melting amount of β-methylnaphthalene in the sweating operation is 31.3% by weight, and the sweating mother liquor is cyclically crystallized. The total crystallization yield was 72.3%.

Embodiment 3

[0029] The high-purity 98.5% β-methylnaphthalene was subjected to film-hanging operation at 10°C for 1.5 minutes, then the temperature of the crystallizer was raised to 25°C, and the raw material of 90.1% β-methylnaphthalene was heated to 40°C and put into crystallization In the device, let the crystal layer grow for 2.0 hours, then cool down at 4°C / h to crystallize and grow the crystal layer for another 5 hours, the thickness of the crystal layer is about 31mm, discharge the crystallization residual liquid and perform sweating operation, the heating rate is 5°C / h, The end temperature of sweating is 28°C, and the crystal is heated to 43°C to melt, and the purity by gas chromatography analysis is 98.66%. The melting amount of β-methylnaphthalene in the sweating operation is 24.9% by weight, and the sweating mother liquor is cyclically crystallized. The total crystallization yield was 83.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com