Toothbrush and toothbrush head for said toothbrush

A technology for toothbrush heads and toothbrushes, applied in the field of toothbrush heads, can solve the problem of not being able to enter the interdental gap easily, and achieve the effect of avoiding bending and large bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

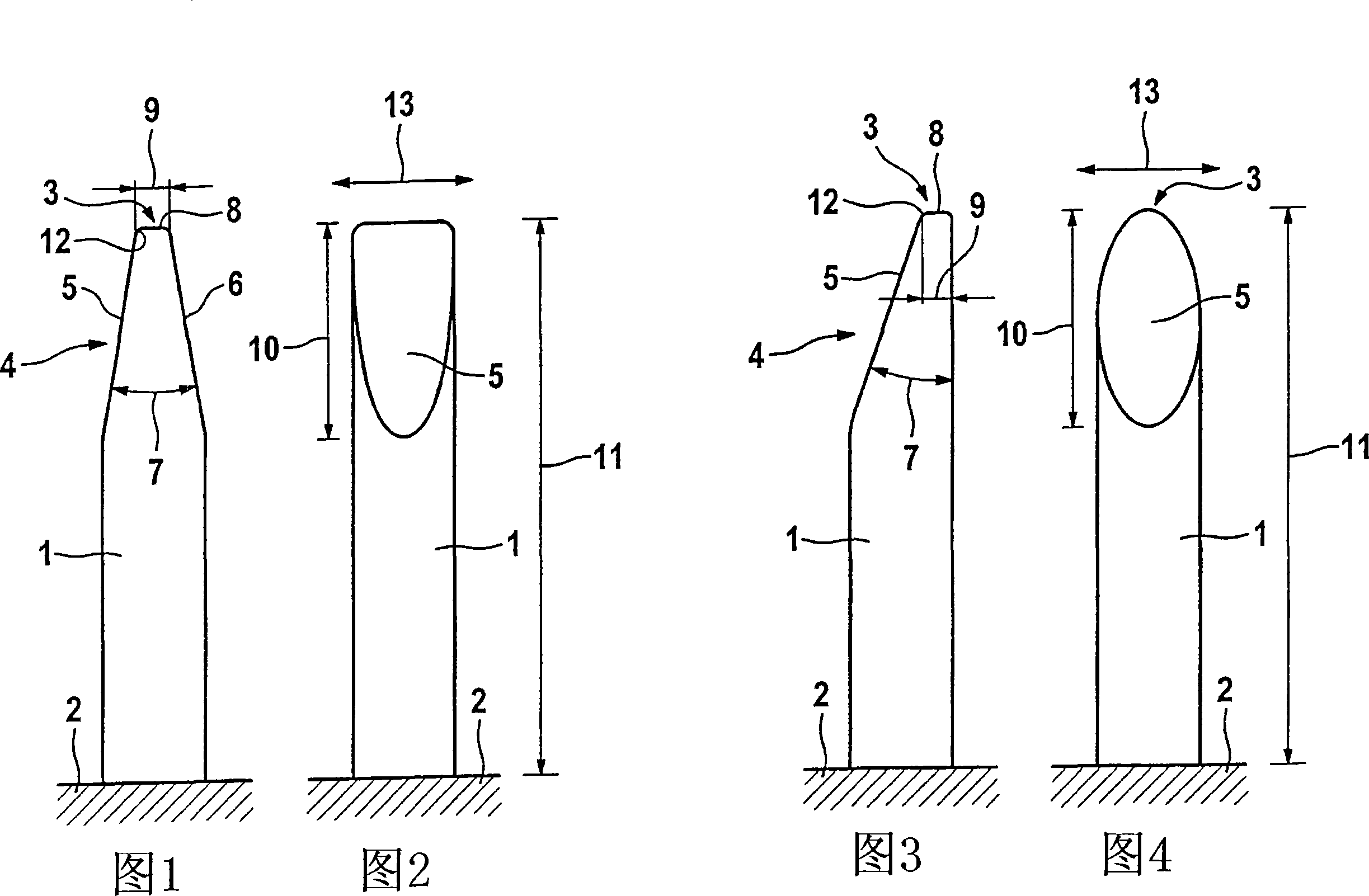

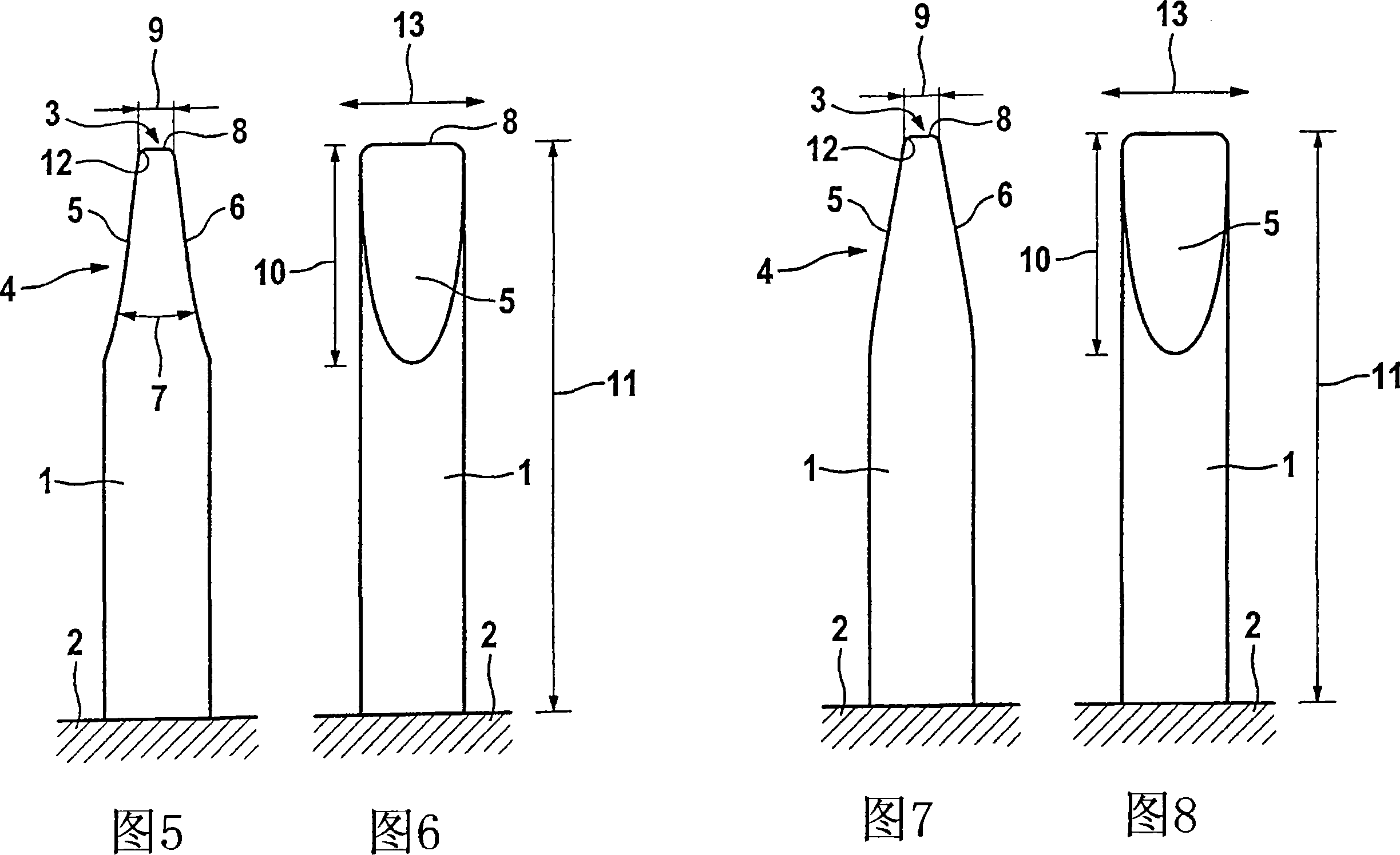

[0037]FIGS. 1 and 2 show filaments or toothbrush bristles 1 which are inserted into a bristle carrier 2 of a toothbrush head which is not shown in detail in FIGS. 1 and 2 . At its root, the filament 1 has a substantially cylindrical shape that sharpens on both sides towards the free end 3 of the filament 1 . In the embodiment according to FIGS. 1 and 2, the sharpening 4 of the free end 3 of the filament 1 is formed by two opposing bevels 5 and 6 forming an acute angle with each other, which are flat in the illustrated embodiment. to constitute. In this case, the two bevels 5 and 6 form a wedge angle 7 of approximately 20° to 25° in the exemplary embodiment shown, wherein the two bevels 5 and 6 are arranged in such a way that they are formed at the free end 3 Ridges in a straight line.

[0038] Therein, in the illustrated embodiment, the sharpening 4 is flattened at its head. The bevels 5 and 6 do not completely merge into a mathematical line at the free end 3 , but are slig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com