Non-linear procedure fault identification method based on kernel principal component analysis contribution plot

A technology of nuclear principal component analysis and fault identification, which is applied in character and pattern recognition, instruments, adaptive control, etc., can solve the problems that cannot be directly identified by fault variables, and the nonlinear mapping function is unknown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0174] Tennessee-Eastman Process

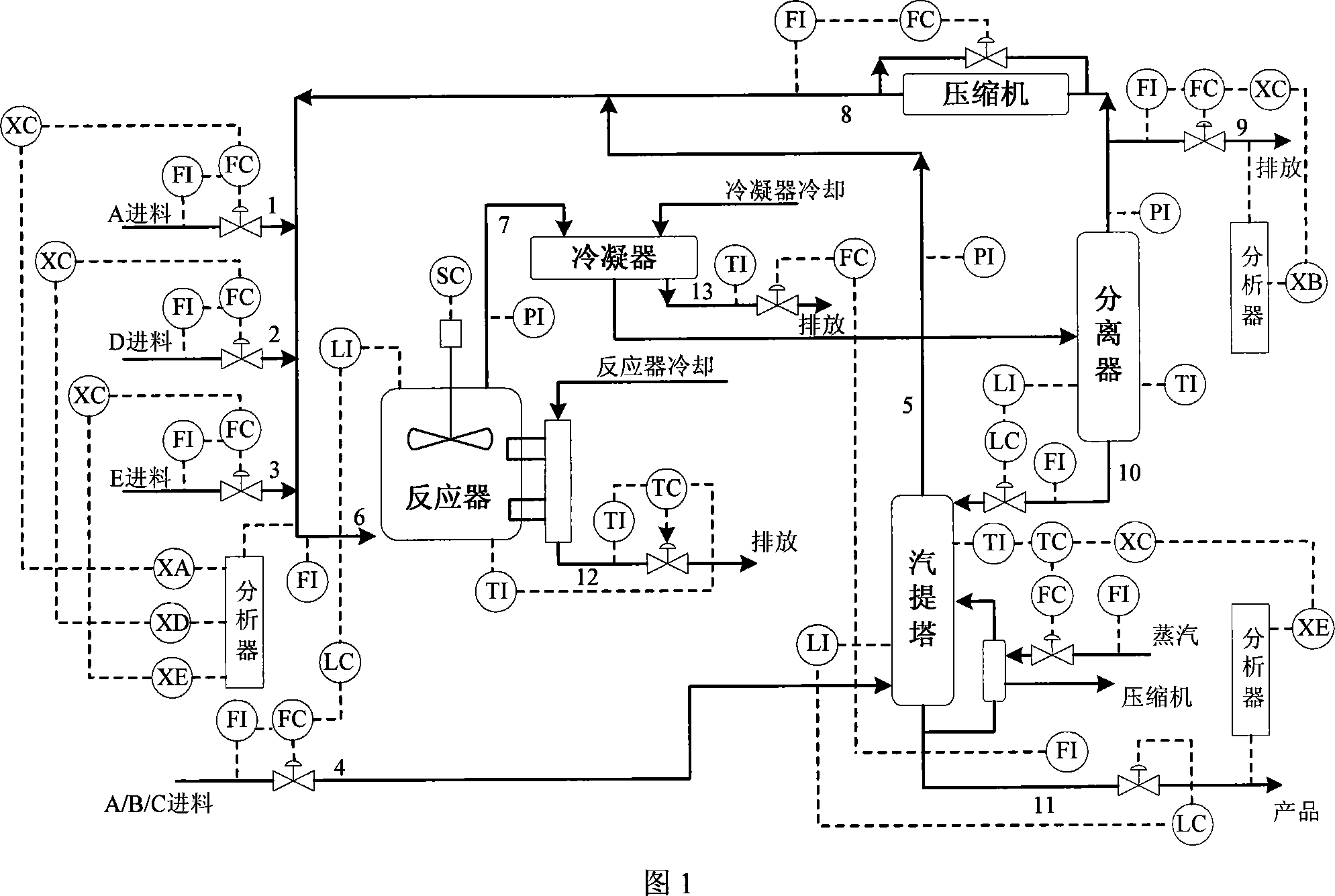

[0175] The method of the invention is applied to the Tennessee-Eastman process simulation data and compared with the original KPCA detection result. The Tennessee-Eastman process is a complex and non-linear process. It was created by Eastman Chemical Company. Its purpose is to provide a real industrial process for evaluating process control and monitoring methods. Control structure like figure 1 Shown. The process includes five main units: reactor, condenser, compressor, separator, and stripper; moreover, it contains eight components: A, B, C, D, E, F, G, and H. The four reactants A, C, D and E are added to the reactor together with the inert component B to form products G and H, as well as by-product F. The Tennessee-Eastman process includes 22 continuous process measurements, 12 controlled variables, and 19 component measurements. As shown in Table 1. In addition to the stirring speed of the reactor's agitator (because it was not controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com