Coating and guiding element for drying machine

A technology for guides and clothes dryers, which is applied in the field of clothes dryers, and can solve problems such as shaking, contact, and inaccurate assembly of painting guides 25, and achieve the effects of easy action control and interference avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below with reference to the drawings and examples.

[0051] Referring to Figure 4 below, Figure 5 A coating guide for a clothes dryer according to an embodiment of the present invention will be described in detail.

[0052] For reference, parts having the same structure as the conventional control unit 22 are denoted by the same symbols.

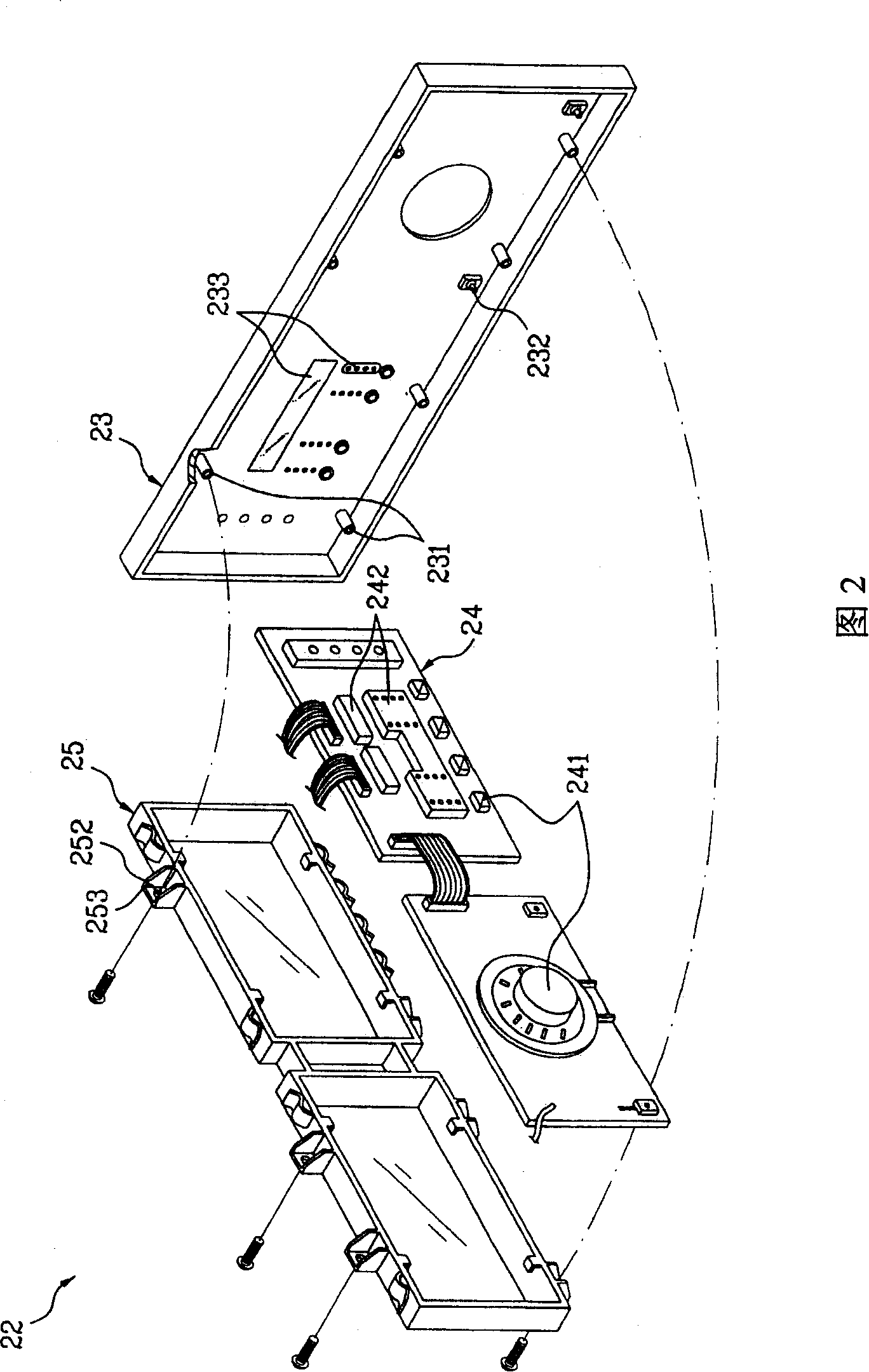

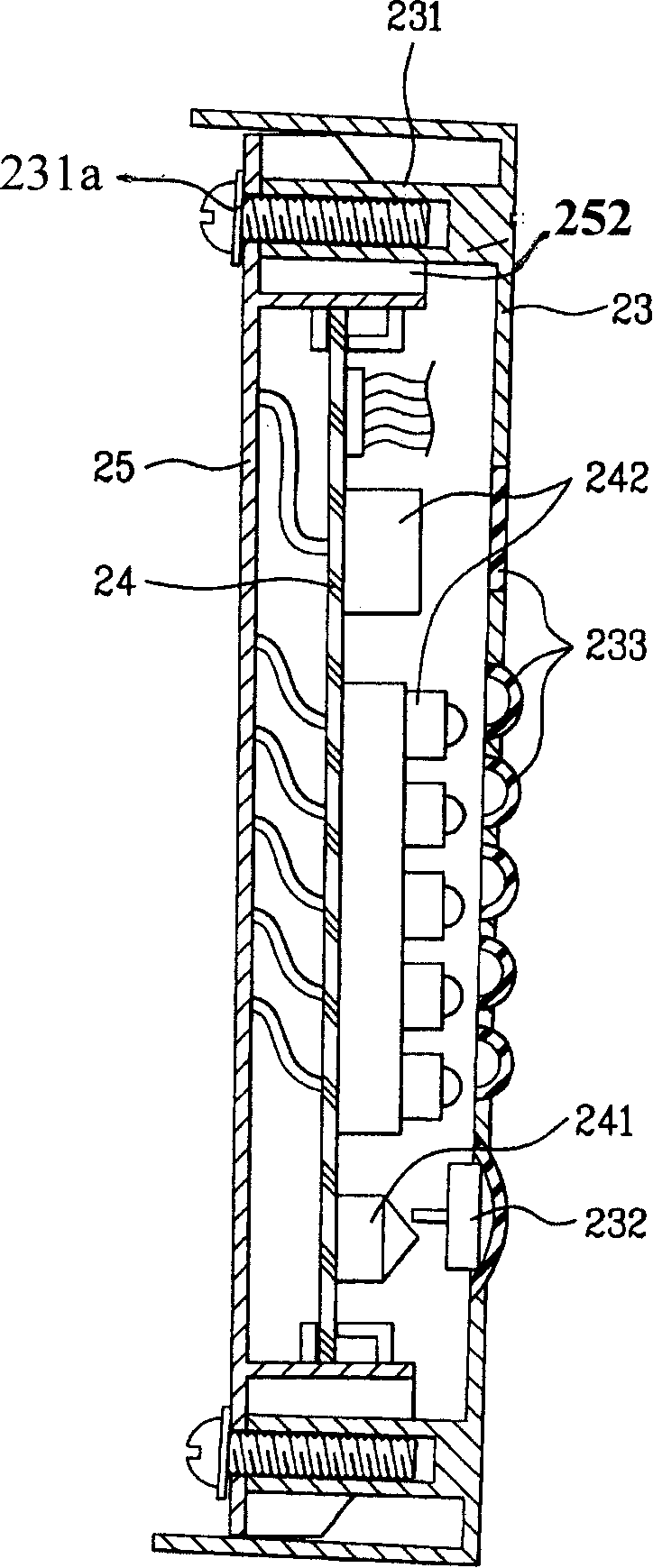

[0053] First, the structure of the control unit 22 of the clothes dryer 1 including the painting guide 25 will be described with reference to FIG. 4 .

[0054] Here, the control part 22 is composed of a control panel 23 forming the appearance of the control part 22; a circuit board 24 on which various electronic components for the operation of the clothes dryer 1 are installed; The coating guide 25 of the coupling part 252 is constituted.

[0055] First, electronic components for controlling the clothes dryer 1 are mounted on the circuit board 24 .

[0056] In addition, on the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com