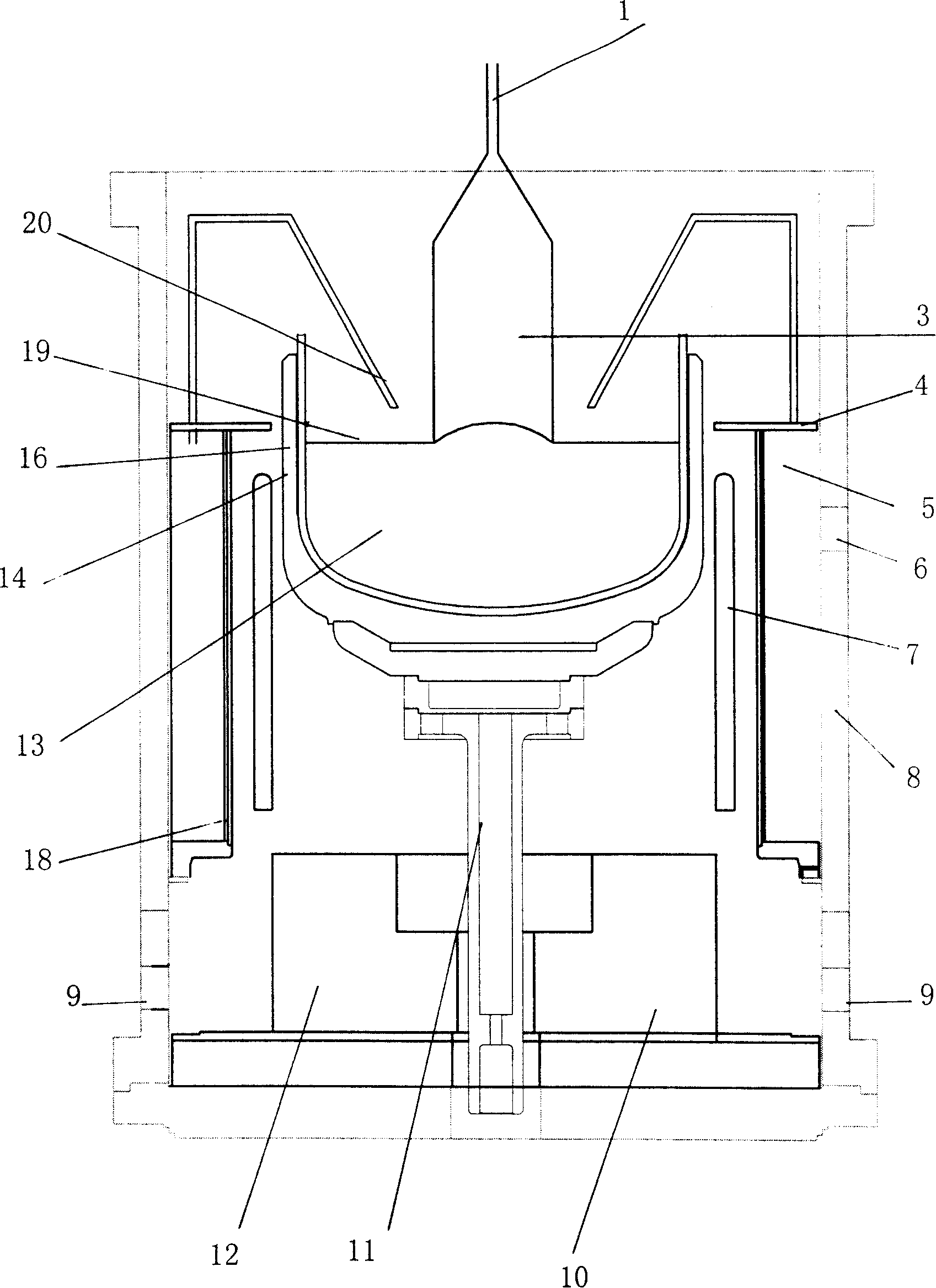

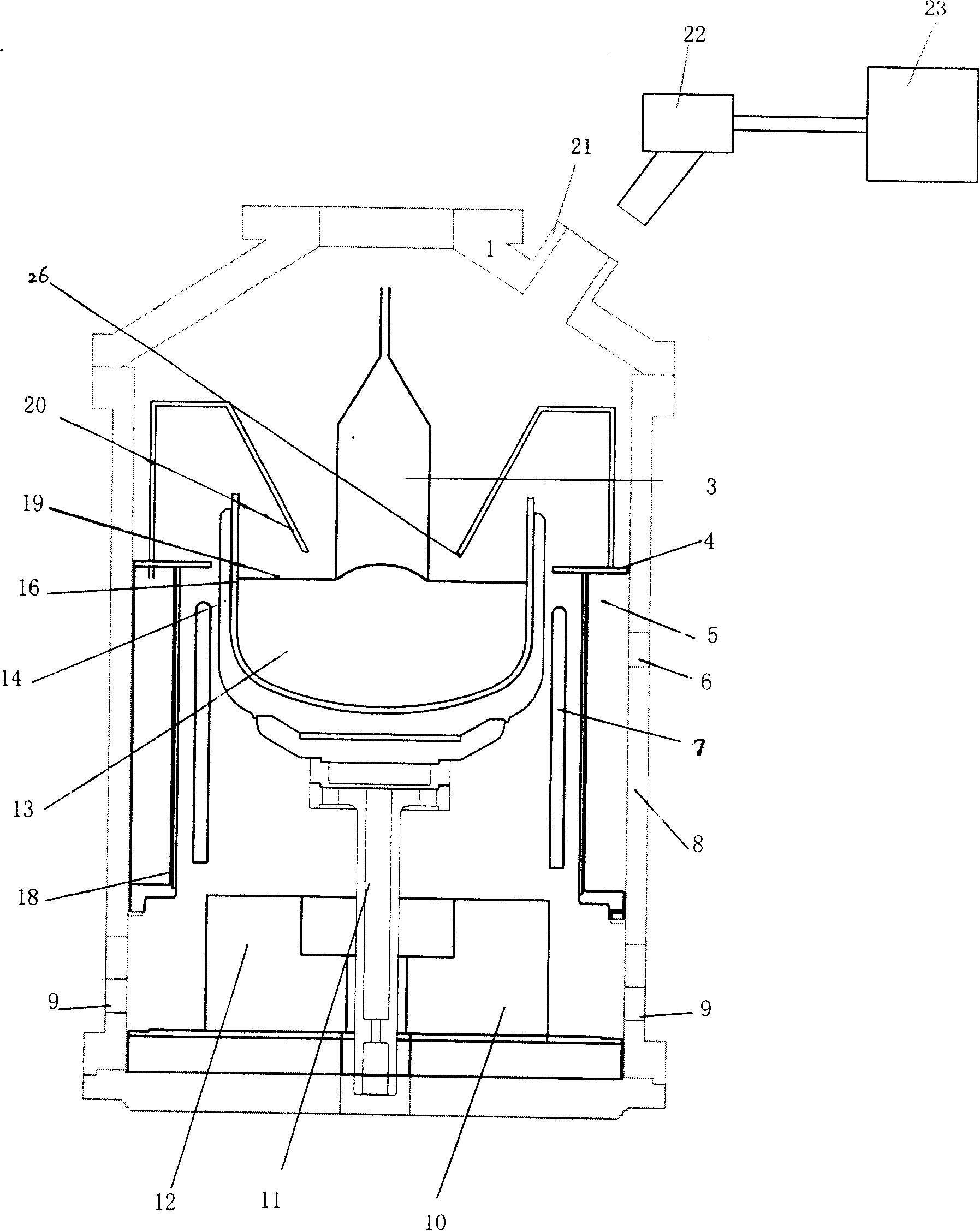

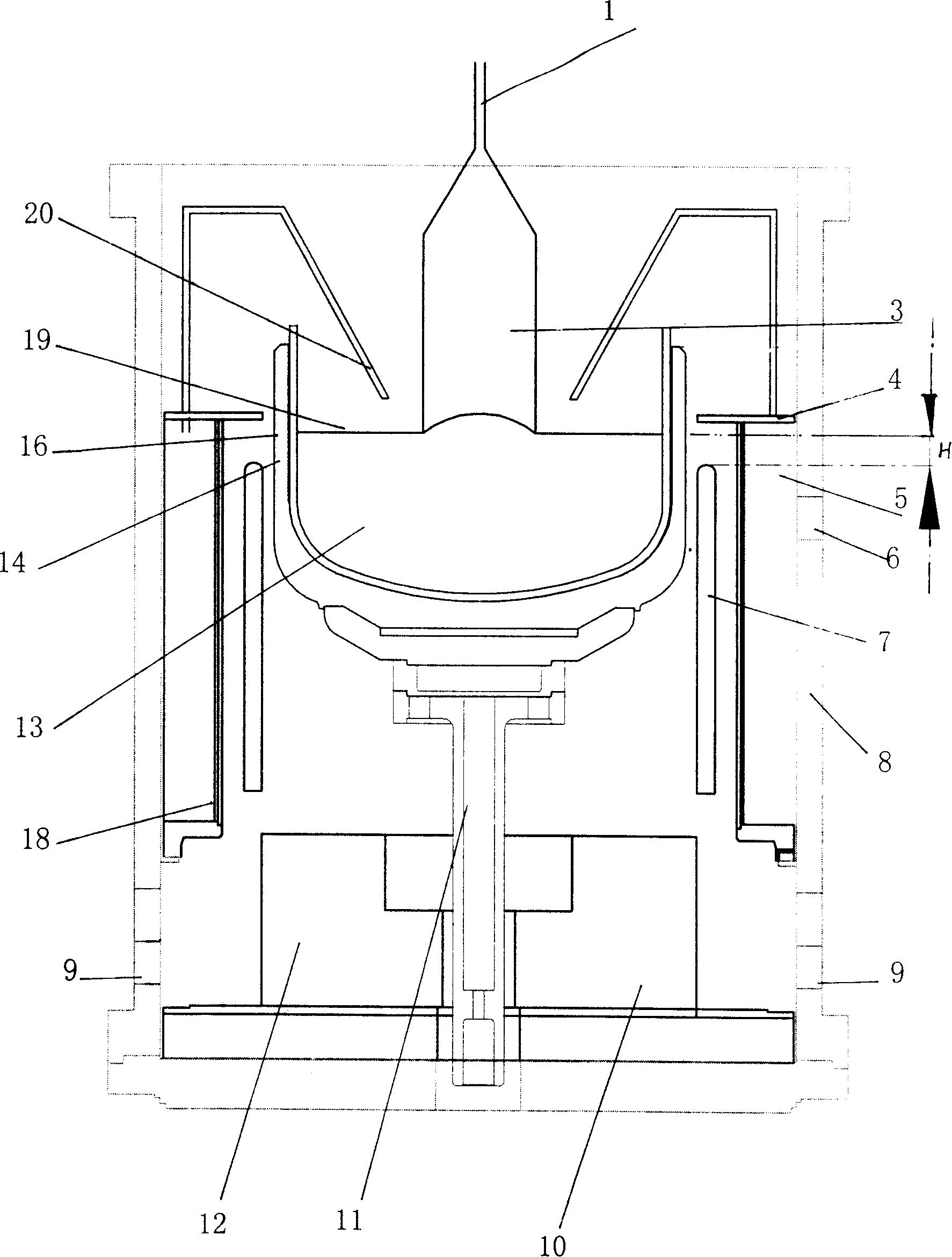

Method for controlling fused silicon liquid level position of czochralski silicon mono-crystal furnace

A technology of Czochralski silicon single crystal and liquid level position, which is applied in the fields of single crystal growth, chemical instruments and methods, self-melting liquid pulling method, etc. Can't work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Example 1. On the KAYEX CG6000 single crystal furnace, use a 16-inch thermal field, charge 50KG, and tell the computer a D 0 The value is 10mm. Using the automatic data calculation function of the computer workstation, the measured value of the actual D is 9.6-10.48mm.

[0045] Example 2. On the KAYEX MCZ150 single crystal furnace, use a 24-inch thermal field, charge 150KG, and tell the computer a D 0 The value is 20 mm. Using the automatic data calculation function of the computer workstation, the measured value of the actual D is 19.52-20.41 mm. The lifting speed of the crucible works just as required, if the actual value of D is greater than 20 mm, then the computer will automatically increase the rising speed of the crucible (14), so that the value of D is reduced to about 20 mm; on the contrary, if the actual value of D is less than 20 mm , then the computer will automatically reduce the rising speed of the crucible (14), making the D value increase to about 20 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com