Multi-head aluminum foil uncoiling mechanism

An aluminum foil and multi-head technology is applied to the aluminum foil unwinding mechanism to complete the unwinding of multiple rolls of aluminum foil at one time. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

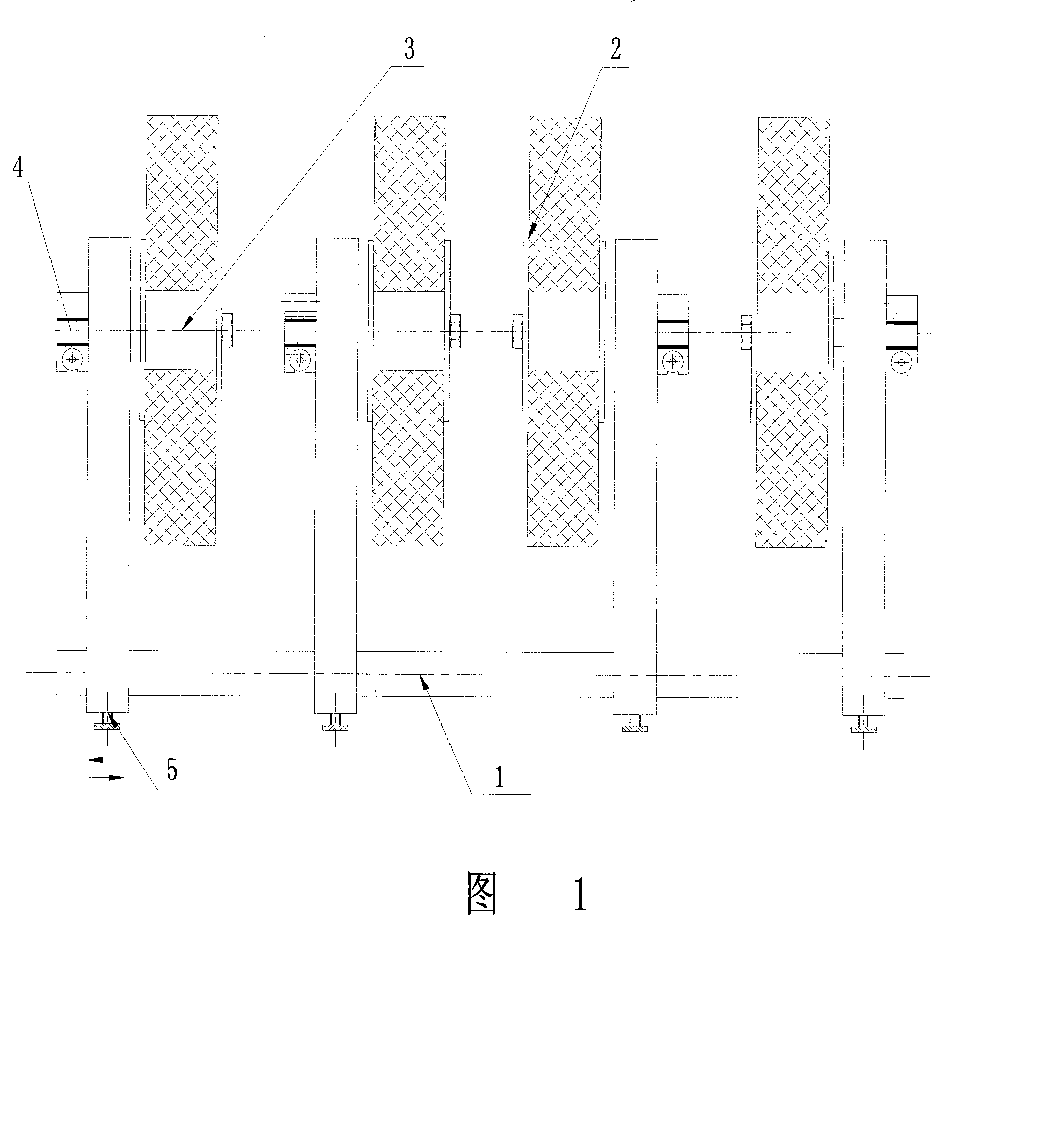

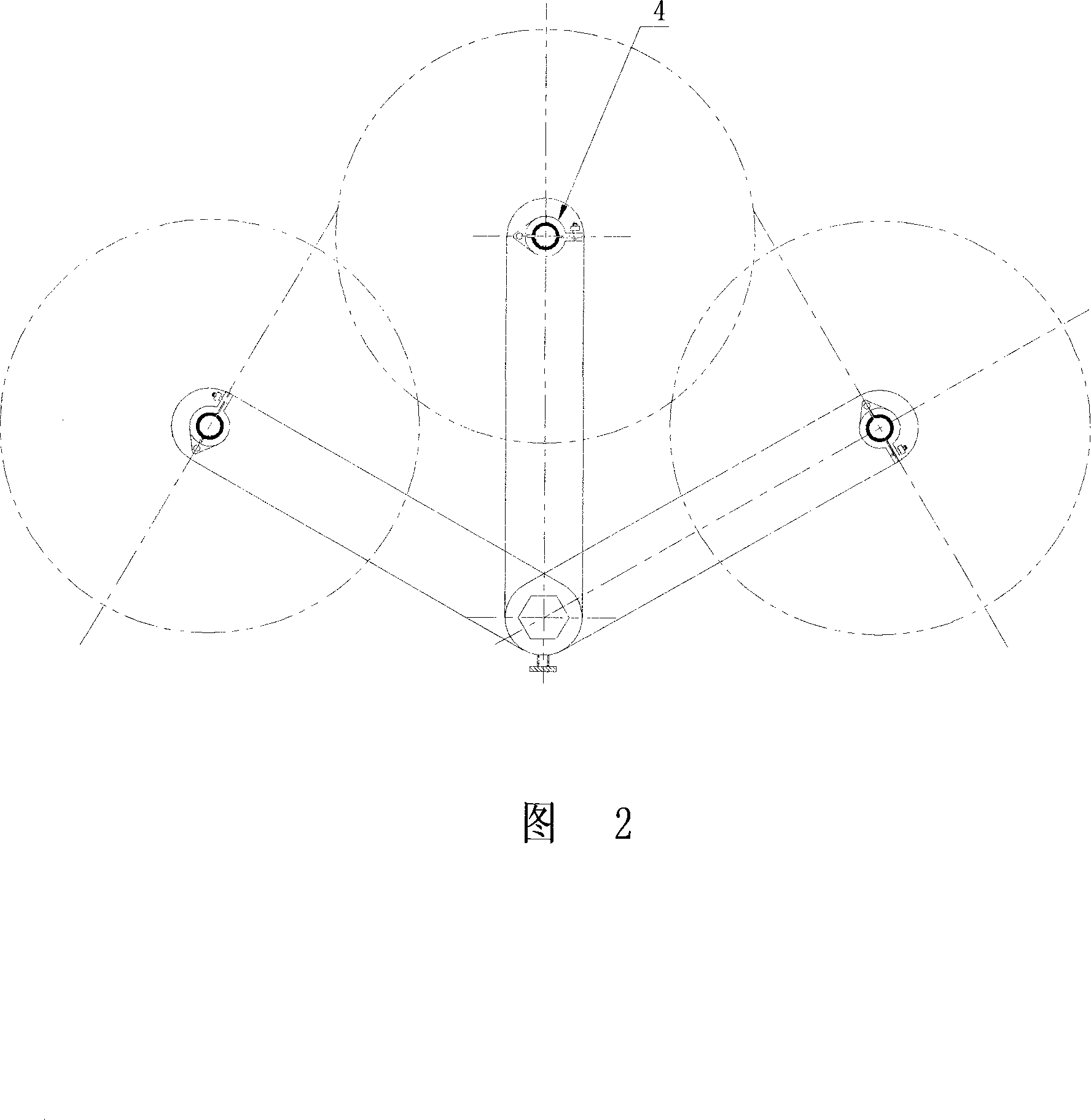

[0019] As shown in the figure, the present invention includes a main shaft 1 and at least one shaft-attached support arm 2, the attached shaft support arm 2 is slidingly connected with the main shaft 1, and the upper end side of each shaft-attached support arm 2 is provided with a transmission support shaft 3, and the other A tension control device 4 is provided on the side.

[0020] The above-mentioned main shaft 1 is a polygonal metal shaft. The lower end of the main shaft 1 is provided with an axial positioning device 5 . The included angle between the shaft-attached arm 2 and the main shaft 1 is 0°-90°. The tension control device 4 is threadedly connected with the shaft-attached arm 2 .

[0021] The present invention adopts V-shaped uncoiling frame, when the included angle between the supporting arm 2 and the main shaft 1 is 60°, the main shaft 1 is hexagonal; the included angle between the supporting arm 2 and the main shaft 1 is 90° , the main shaft 1 is a quadrangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com