Lubricant composition

A lubricant composition and additive technology, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of insufficient machine performance and shortened life, and achieve the effects of suppressing rotational torque, reducing friction, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

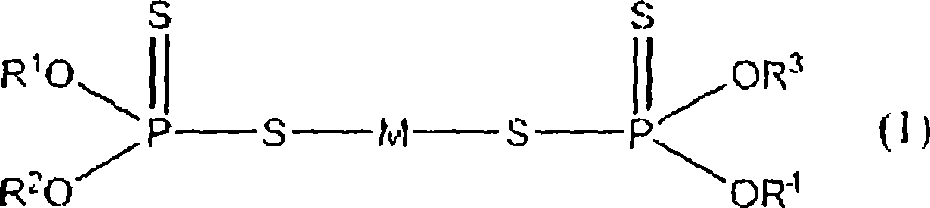

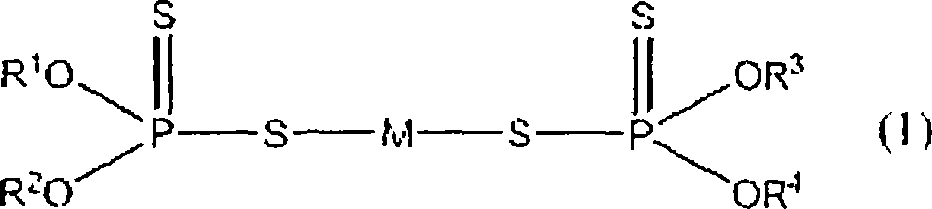

Method used

Image

Examples

Embodiment 1

[0079] Mix 20 g of polyol ester (lubricating machine oil, manufactured by Castrol Corporation, trade name: AISM CHICSUK) and 0.04 g of YUSILAB (trade name, organometallic, manufactured by Yushiro Chemical Co., Ltd.) to prepare a lubricant composition and store it in a container middle. Next, 30 g of HFC-134a was injected into the above-mentioned lubricant composition as a mixed refrigerant. The kinematic viscosity of this mixed refrigerant is 46m 2 / s. In addition, kinematic viscosity is measured on the temperature condition of 40 degreeC based on standard ASTM D445.

Embodiment 2

[0081] A lubricant composition was prepared by mixing 200 g of ECOSTAGE (trade name, lubricating engine oil, manufactured by Nippon Oil Corporation) and 2 g of YUSILAB, and this was used as a lubricating oil for an internal combustion engine. The kinematic viscosity of this lubricating oil for internal combustion engines is 46m 2 / s. In addition, the kinematic viscosity is measured in accordance with standard ASTM D445 under the temperature condition of 40 degreeC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com