Sliding desk type casing tube abrasion testing machine

A technology of wear test and testing machine, which is applied in the direction of testing wear resistance, testing of machine/structural components, measuring devices, etc., to achieve the effect of adjustable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

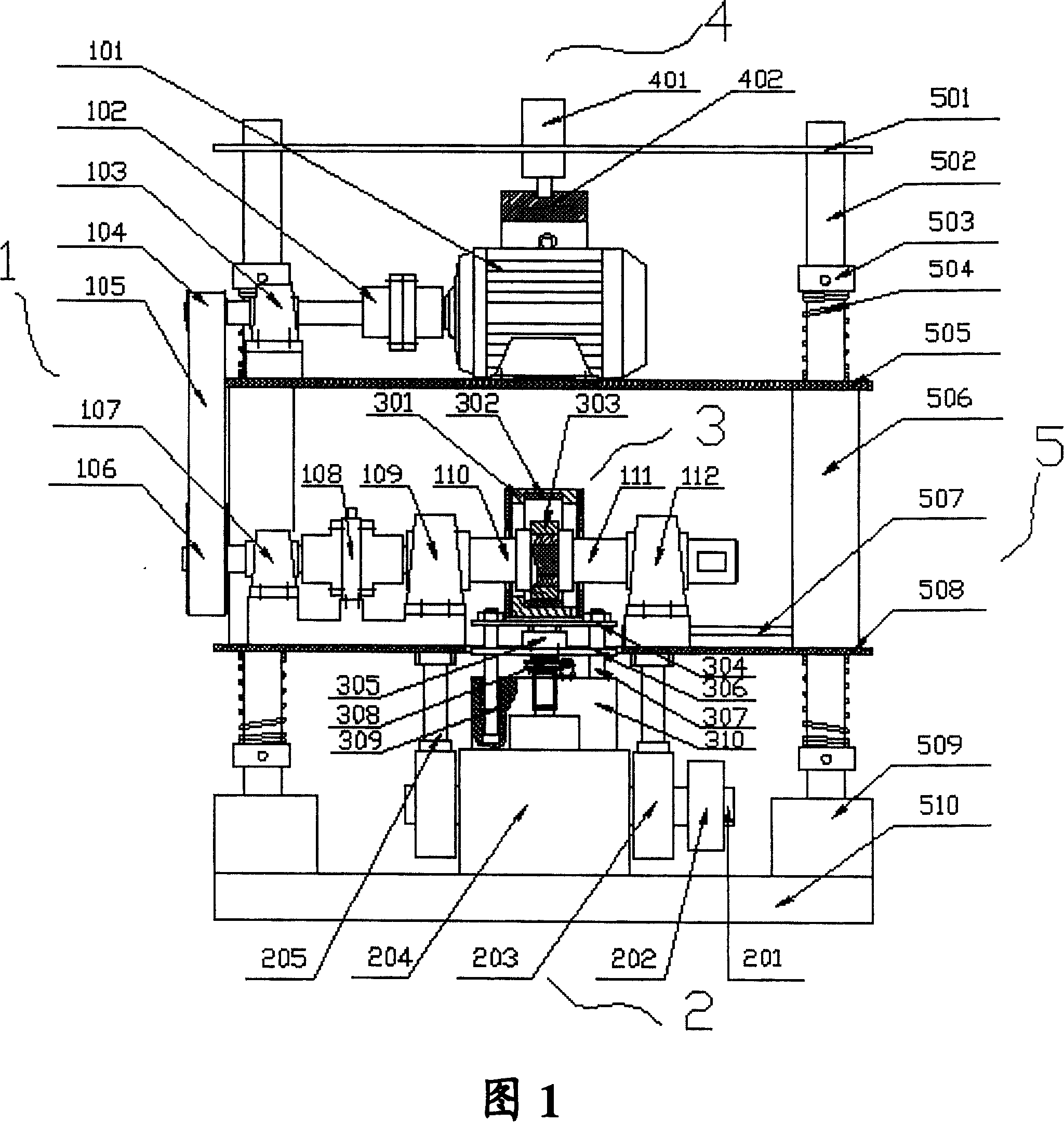

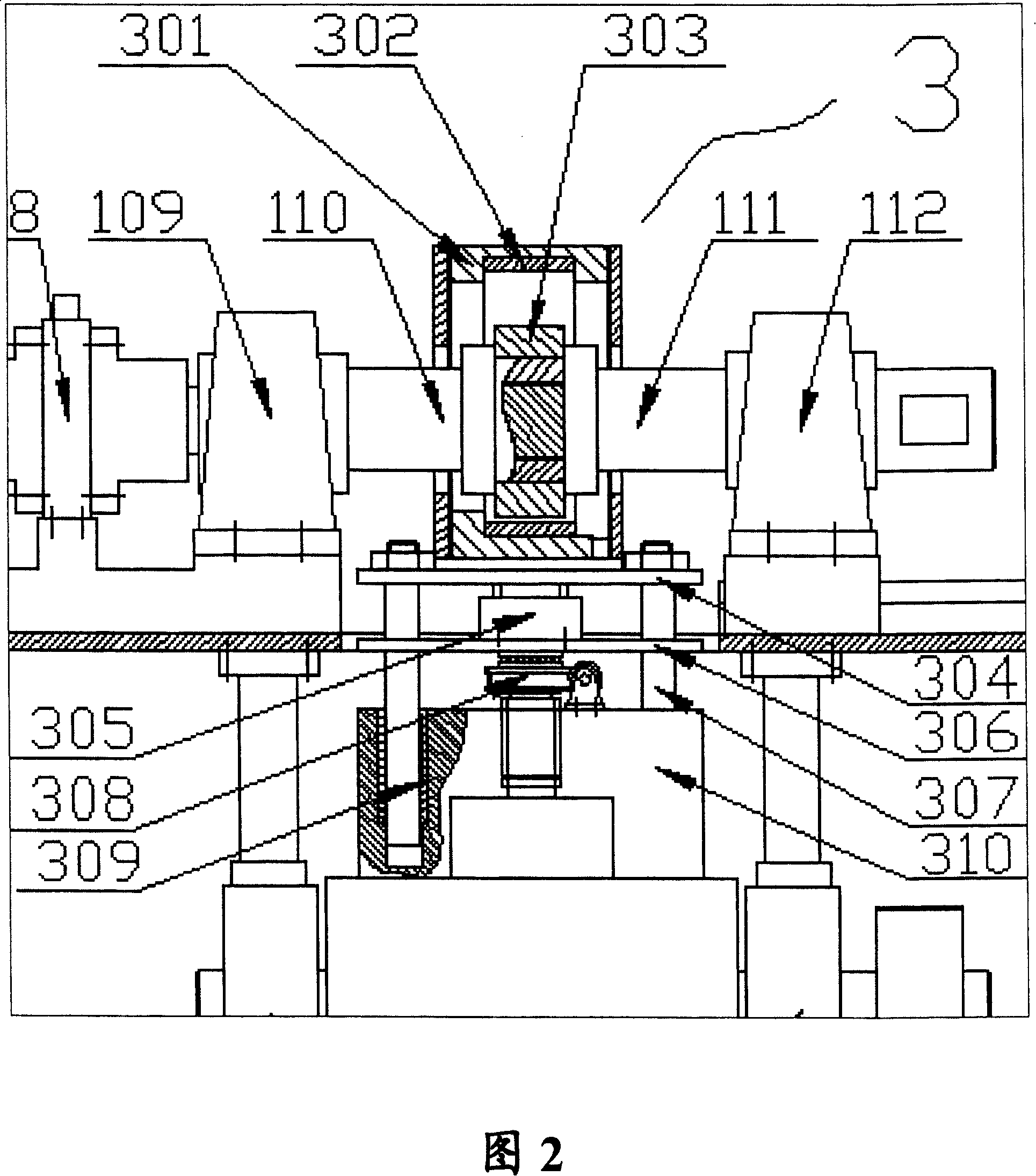

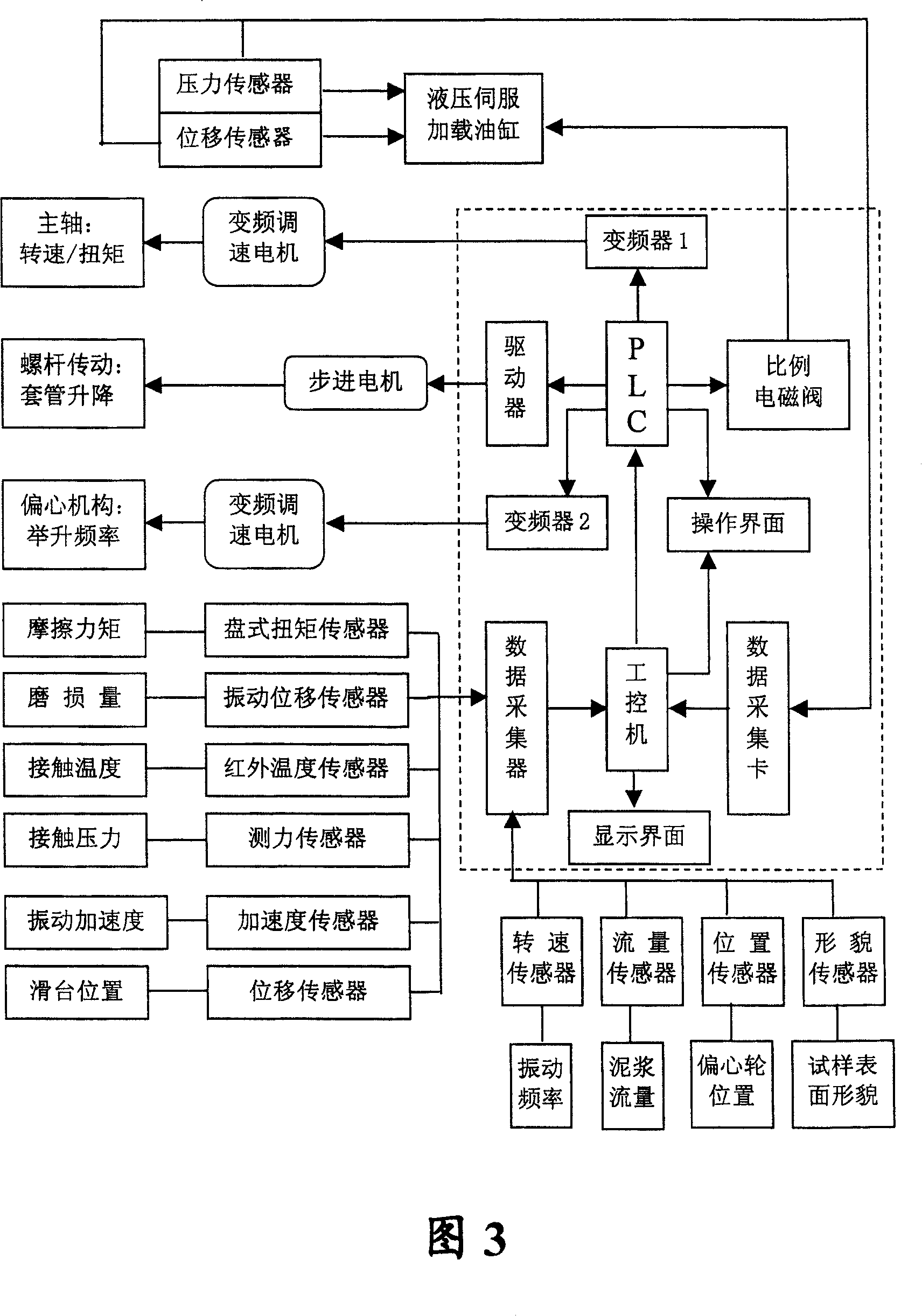

[0038] As shown in Figures 1 to 4, the present invention proposes a sliding table casing wear testing machine, which includes a transmission system 1, an excitation system 2, a clamping system 3 and a frame 5, and a rotating transmission shaft 110 of the transmission system 1. The first test piece is fixed and clamped on the upper part, the second test piece is installed in the clamping system 3 corresponding to the first test piece, the transmission system 1 drives the first test piece to rotate around the axis, and the frame 5 is provided with at least A sliding platform, the transmission system 1 is arranged on the sliding platform, and the excitation system 3 can drive the sliding platform to vibrate up and down, that is, the excitation system 2 can drive the entire transmission system to vibrate up and down, thereby dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com