Automatic control method of roll type pipe correction machine

A straightening machine and roller-type technology, which is applied in the field of automatic control of roller-type tube straightening machines, can solve problems such as unstable straightening effects and achieve stable straightening effects

Inactive Publication Date: 2010-12-01

NIPPON STEEL CORP

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the offset amount and rolling amount are manually set based on the experience and intuition of the operator as described above, the correction effect is still unstable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

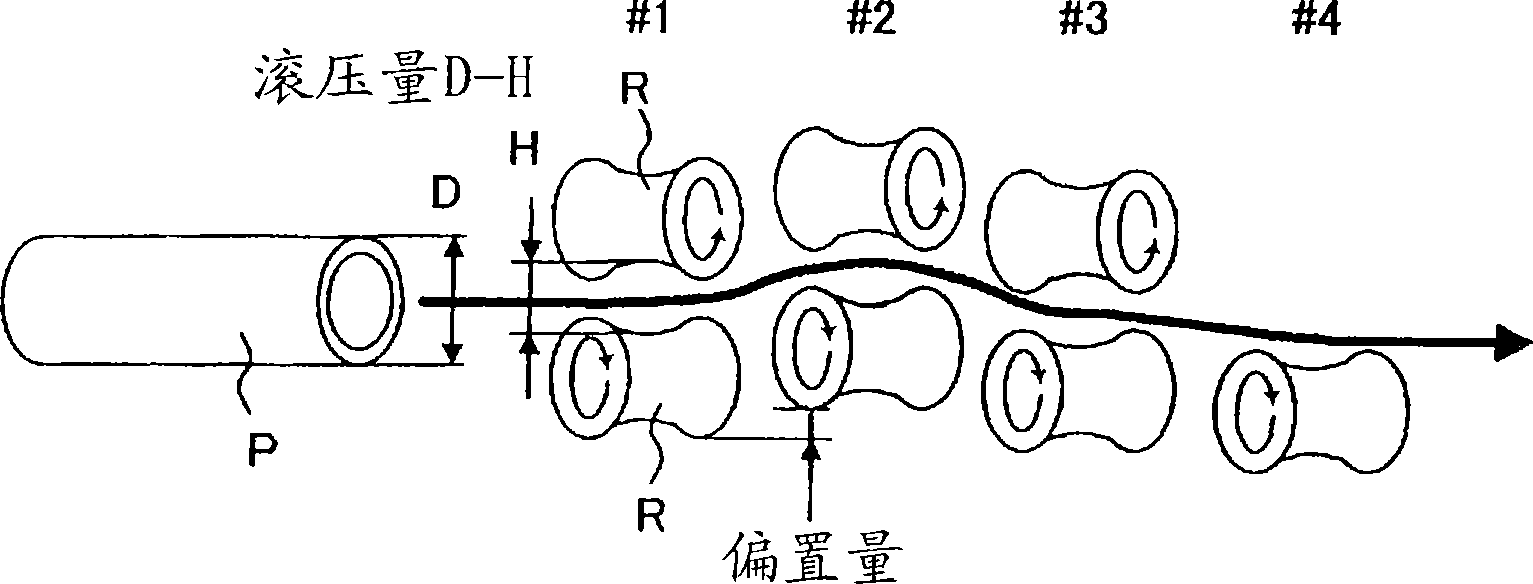

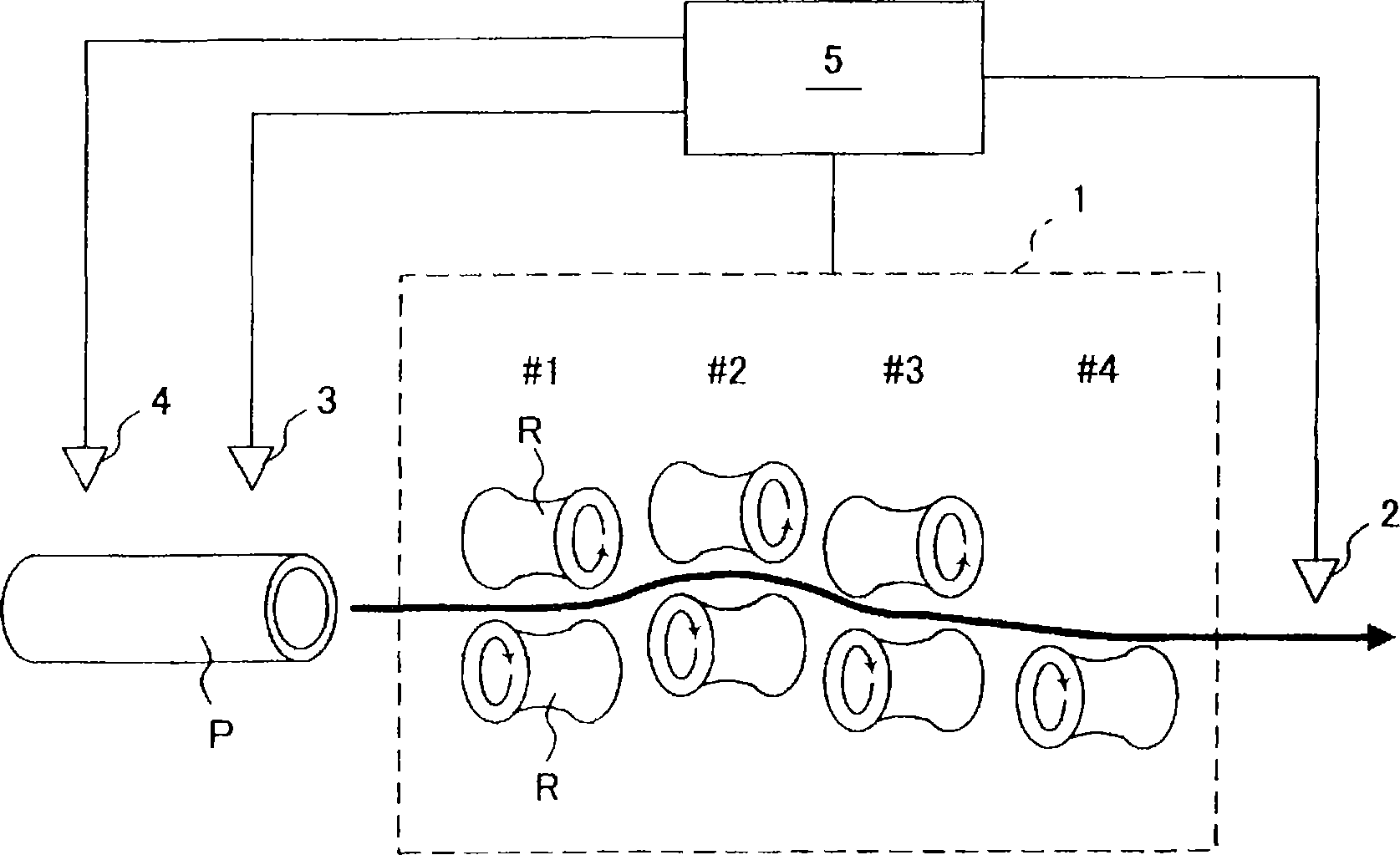

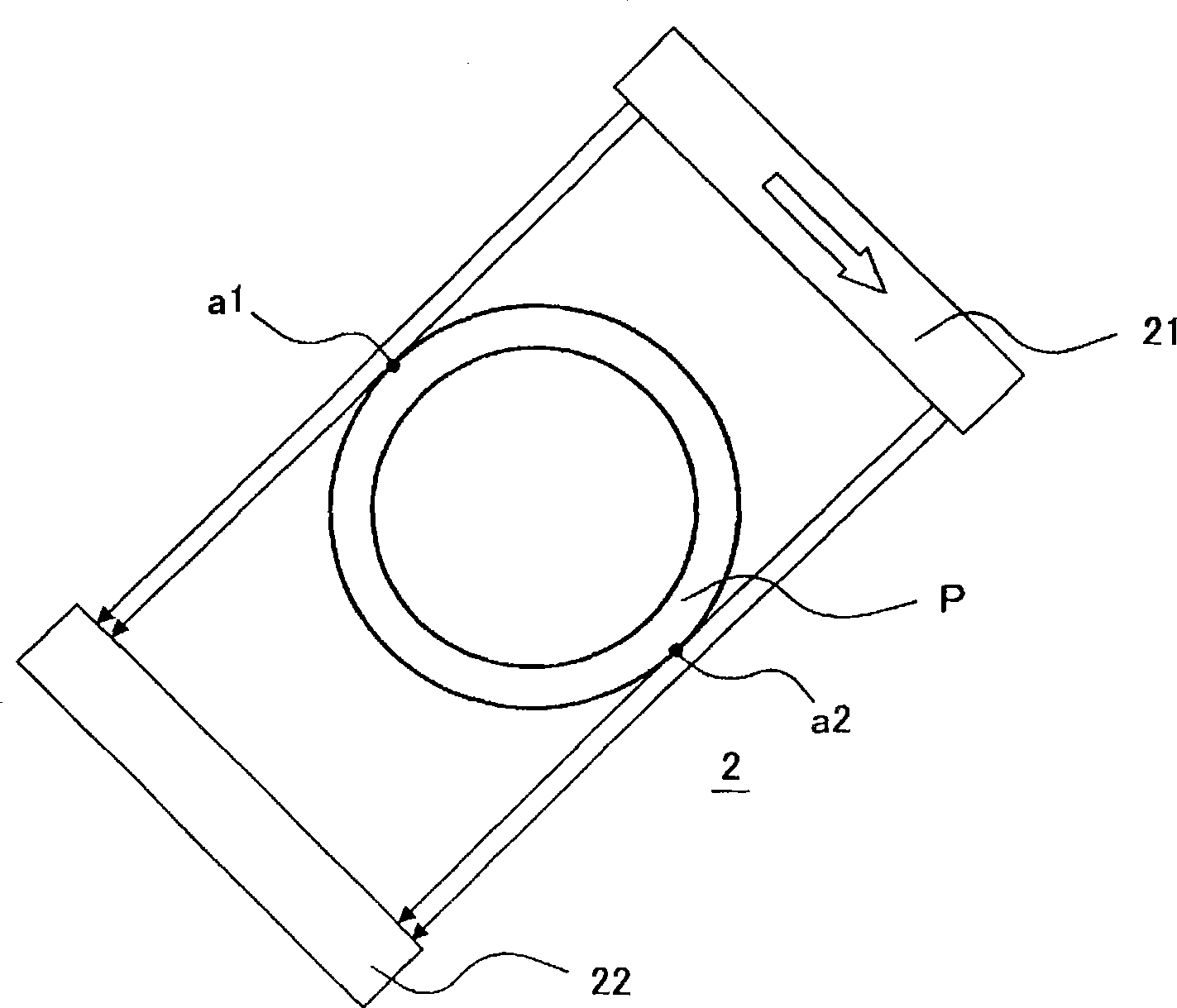

Automatic control method of a roll type pipe correction machine producing a stabilized correction effect. At the time of correcting a pipe by crushing it by means of a straightener equipped with three or more stands each having a pair of hole type rolls, automatic control of first through fourth steps is carried out. First step: the relation between a set value of the offset amount and the bending amount of a pipe measured on the exit side of the correction machine is calculated previously. Second step: the bending amount of the pipe is measured on the exit side of the correction machine. Third step: when the bending amount measured in the second step is out of a target range, a variation of the offset amount for limiting the bending amount of the pipe on the exit side of the correction machine within the target range is calculated according to the relation calculated in the first step. Fourth step: a set value of the offset amount at the time of correcting the next pipe is determinedaccording to the variation of the offset amount calculated in the third step.

Description

Automatic Control Method of Roller Tube Straightening Machine technical field The present invention relates to an automatic control method of a roller pipe straightening machine for straightening steel pipes and the like, and particularly relates to an automatic control method of a roller pipe straightening machine capable of obtaining stable straightening effects. Background technique Pipes manufactured by various pipe manufacturing methods are subjected to various treatments and finished in order to obtain predetermined quality. The straightening step is one of the finishing steps, and its purpose is to eliminate the bending of the manufactured pipe to make it straight, and to change the outer shape of the pipe from an ellipse to a perfect circle. As shown in FIG. 1 , a generally used roller tube straightening machine (straightening machine) includes three or more rolling mills provided with a pair of facing grooved rolls R, R. The roller tube straightening machine mak...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21D3/02B21D3/14

CPCB21D3/04

Inventor 岸真友

Owner NIPPON STEEL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com