Pneumatic shifting device

A technology of pneumatic shifting and mounting holes, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of poor maintainability and assembly, low efficiency, frequent manipulation, etc. The layout, the overall structure is simple, and the inspection and maintenance are convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

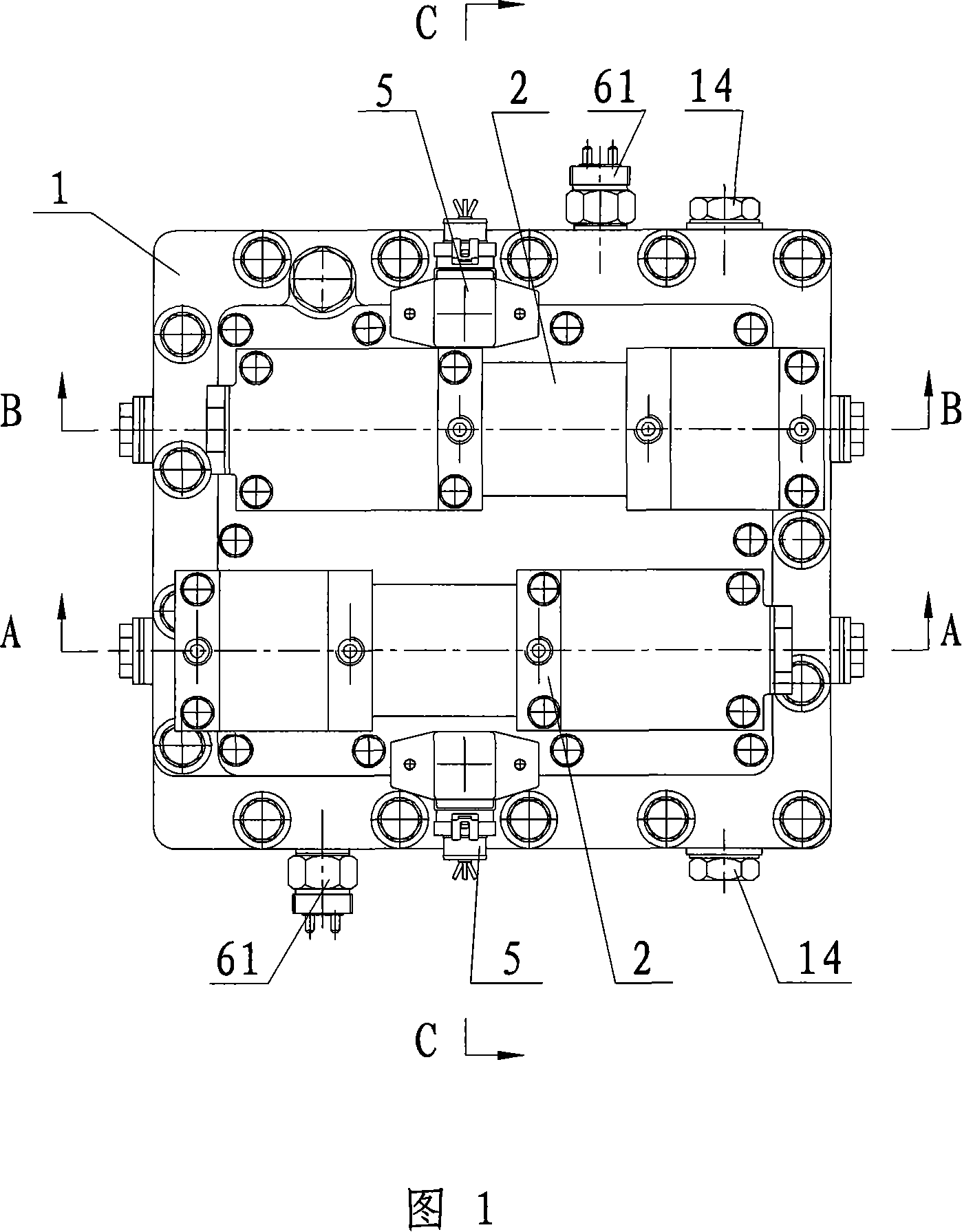

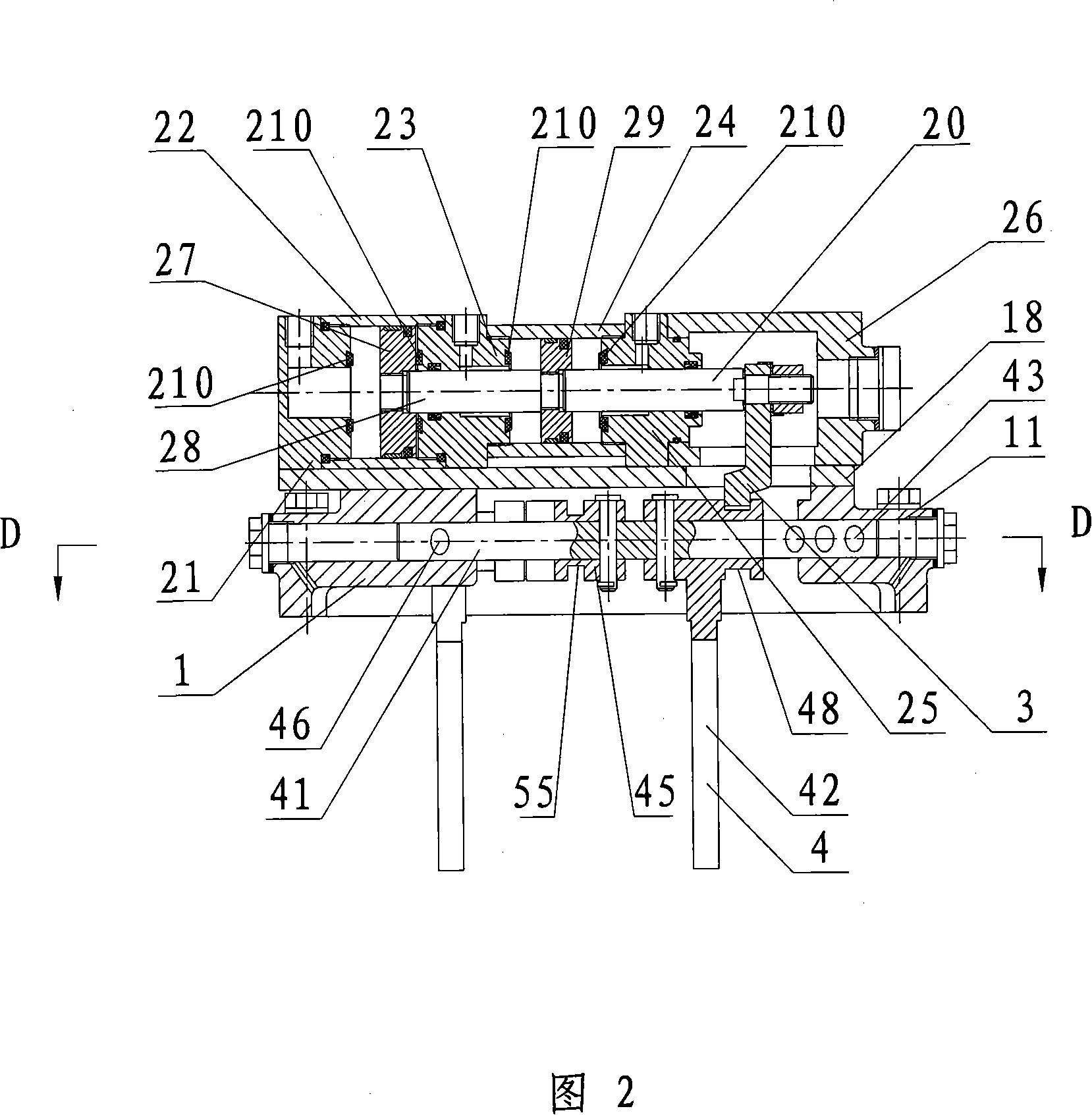

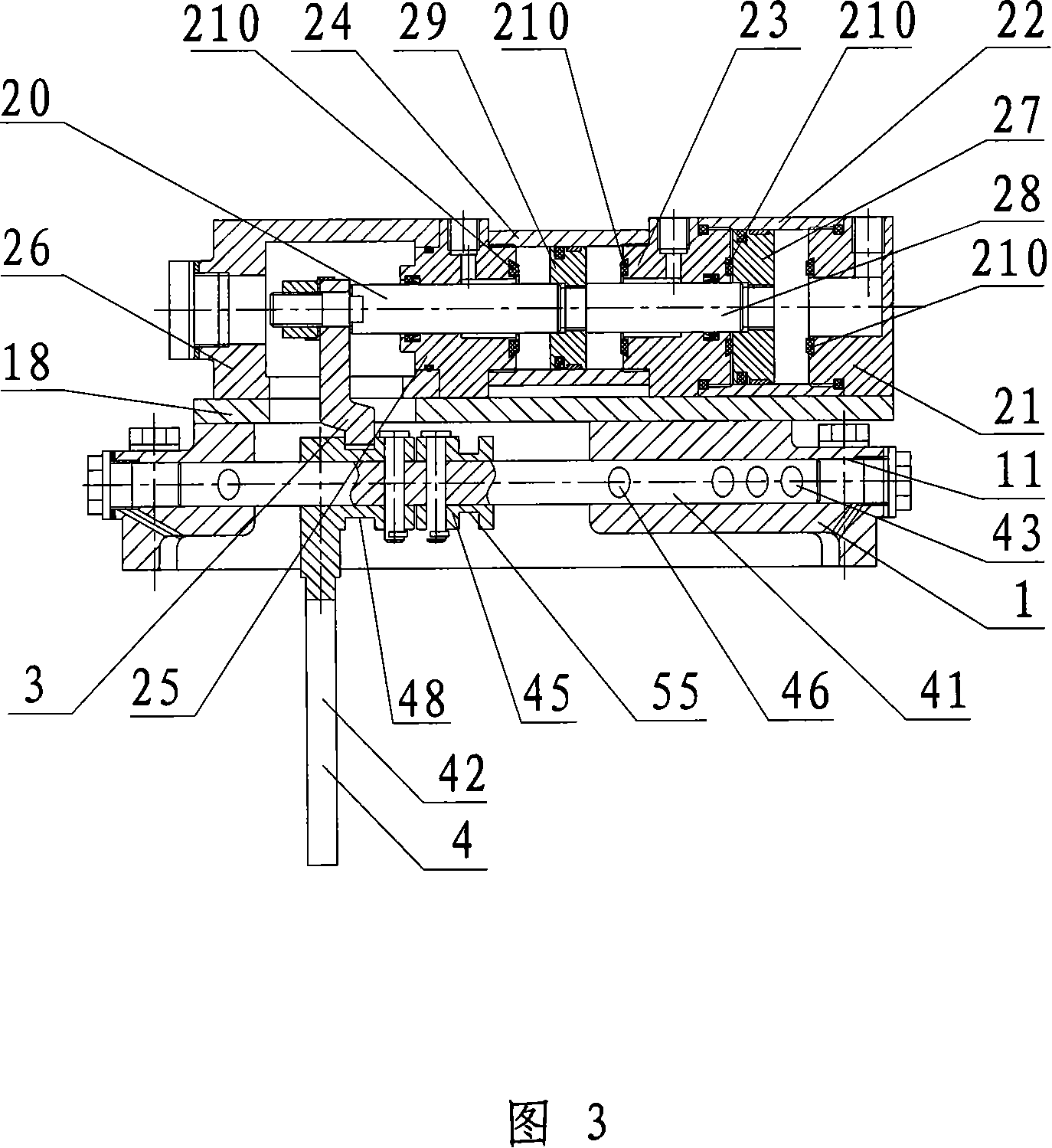

[0048]As shown in Figures 1 to 5, a pneumatic shifting device of the present invention includes a housing 1, two actuators 4 are installed in the housing 1, a connecting plate 18 is installed on one side of the housing 1, and the connecting plate 18 is equipped with two drive cylinders 2 controlled by the electromagnetic valve control device, and the two drive cylinders 2 are respectively the first drive cylinder and the second drive cylinder. Each driving cylinder 2 comprises a cover plate 21, a large cylinder block 22, a connection seat 23, a small cylinder block 24, a supporting cover 25 and a cylinder head 26 connected one by one, and the cover plate 21, the large cylinder block 22 and the connection seat 23 encircle a large cavity body, a large piston ring 27 is set in the large cavity, a large piston ejector rod 28 fixedly connected with the large piston ring 27 is set in the connecting seat 23, and a small cavity is surrounded by the connecting seat 23, the small cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com