Mortar stirring device

A mortar mixing and external mixing technology, which is applied in the field of mixing machinery, can solve the problems of single mortar flow direction and insufficient mixing of mortar components, and achieve the effect of sufficient mixing and avoiding air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

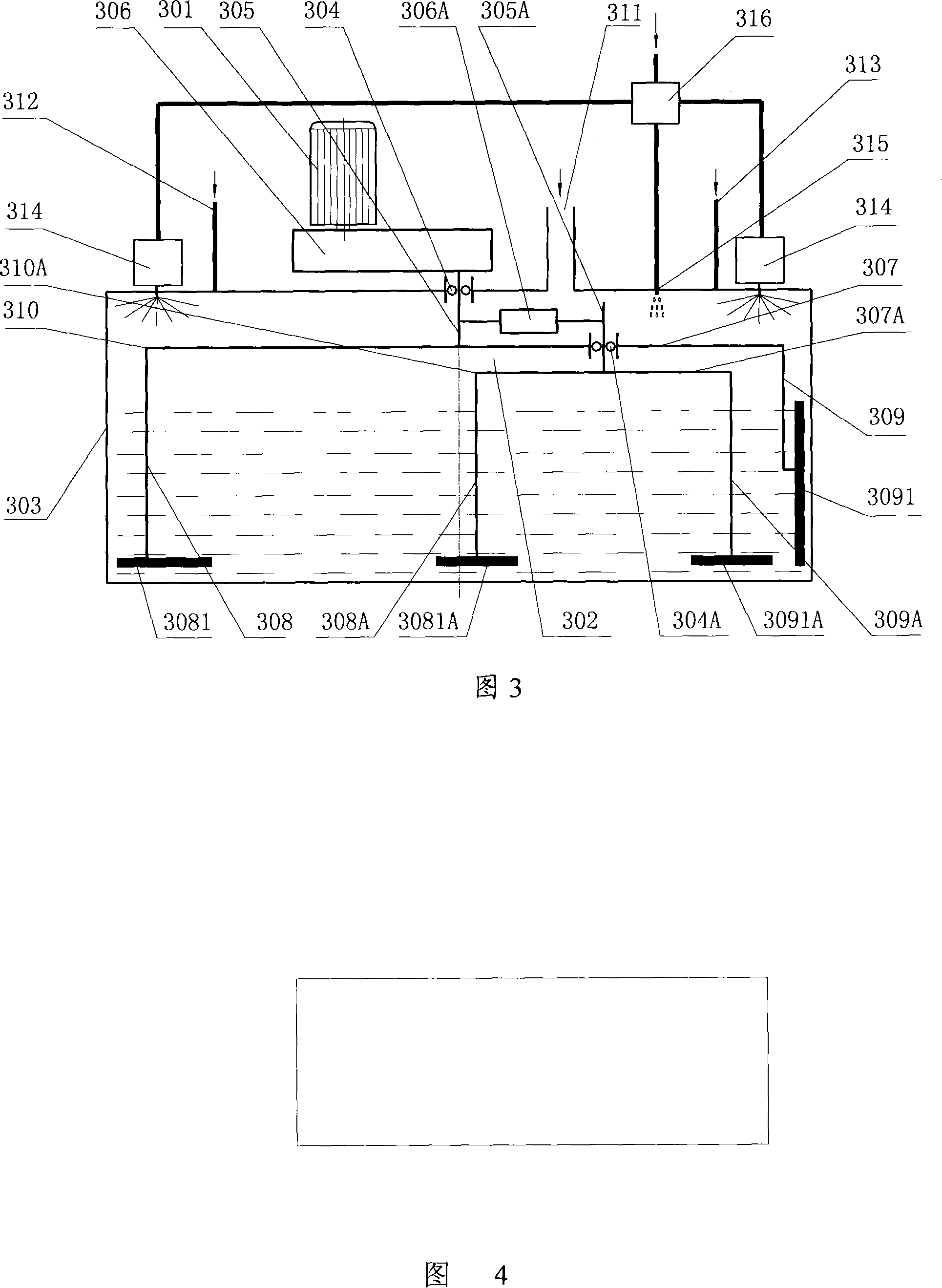

[0027] Please refer to FIG. 3 , which shows the structure of the mortar stirring device provided by the first embodiment of the present invention.

[0028] As shown in FIG. 3 , the mortar stirring device includes a motor 301 , a stirring mechanism 302 , and a bucket 303 . Wherein the material barrel 303 is a cylinder with a top cover, and its interior is used to place mortar; the material barrel 303 is also a base for placing other mechanisms. Motor 301 is installed on the top cover of material bucket 303, and this top cover also has the opening of various feeding pipes, water inlet pipe etc., and connects corresponding pipeline. A first bearing 304 with a vertical axis is installed in the center of the top cover of the bucket 303 , and the vertically arranged main shaft 305 of the stirring mechanism 302 is installed on the first bearing 304 . The first transmission mechanism 306 connects the motor 301 and the main shaft 305 of the stirring mechanism 302 , and the function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com